Tjernlund SS2 SideShot (Discontinued Version - Pre UC1 Universal Control) 8504063 Rev B 11/99 User Manual

Page 13

12

DRAFT ADJUSTMENT PROCEDURE

The SS2 Vent system will properly vent a wide range of BTU/hr. input capacities. To compensate for different burner capacities,

vent connector lengths, types and sizes, it features a draft adjustment located on the back of the venter assembly. Turning this

draft adjustment knob clockwise will increase draft and raise the BTU capacity. Turning the knob counter-clockwise will decrease

draft and lower the BTU capacity. The SS2 is factory set for the highest draft (BTU capacity).

IMPORTANT:

Before proceeding, close all windows, doors and fireplace dampers. Turn on all appliances in the structure that exhaust indoor air

such as clothes dryer, exhaust fans, range hoods, bathroom and whole house exhaust fans. Failure to perform the draft adjust-

ment procedure may cause a poor vent system installation possibly resulting in fire, carbon monoxide poisoning, explosion, per-

sonal injury or property damage.

1. Insert a stack thermometer into the vent pipe as close as possible to the SS2 inlet. NOTE: plug hole when finished with installation.

2. Adjust barometric draft control to the minimum or least draft setting.

3. Place the heating system into operation. NOTE: There will be a slight pause between the venter operation and the burner operation.

4. Continuously monitor the over fire draft and adjust the SS2 draft adjustment knob to maintain a reading of -.02 to -.03” W.C..

When the flue gas temperature at the venter inlet has stabilized make any final draft adjustment necessary to maintain a

reading of -.02 to -.03” W.C.. IMPORTANT: If a minimum of -.02” W.C. cannot be obtained with the SS2 draft adjustment

knob turned fully clockwise, close the burner air shutter until a reading of -.02” W.C. is obtained.

5. Perform a smoke test and make any adjustments to the burner air shutter and venter draft adjustment to arrive at a trace of

smoke (between 0 and 1) at a minimum over fire draft of -.02” W.C..

6. Perform a CO

2

test at the same location as the smoke test. Reduce the CO

2

1% to 2% by opening the burner air shutter.

Recheck over fire draft and increase venter draft if necessary to maintain a minimum of -.02” W.C.. IMPORTANT: Depending

on installation variables it may be necessary to operate burner at CO

2

levels of 12% to 13% with firing rates over 1 GPH to

maintain a minimum of -.02” W.C. over fire draft. Consult factory at 1-800-255-4208 if you experience burner setup problems.

Do not allow heating system to run at less than a -.02” W.C. over fire draft or at a CO

2

level that is less than a 1% reduction from

the value measured at a trace of smoke and a -.02” W.C. over fire draft. If these parameters are unobtainable, contact Tjernlund at

1-800-255-4208 for Technical Assistance.

7. Remove the call for heat from the heating system. NOTE: The SS2 will run in post-purge mode from the Relay/Timer. Allow

the system to cool down to ambient room temperature.

8. Restart the heating system.

9. At 5 minutes into the restart, read and record the inlet temperature ________F, ________C. If

this temperature is above 250

0

F (121

0

C)., continue to step 10. If this temperature is below

250

0

F (121

0

C), insulate the pipe with an approved pipe insulation. Verify that the over fire draft

and CO

2

have not changed, If they have, redo the adjustment steps. With the pipe insulated,

redo the 5 minute temperature test and record the new value here ________F, ________C. If

insulating the pipe did not increase the inlet temperature above 250

0

F. (121

0

C) within 5 minutes

of the heating system call for heat, call 800-255-4208 for technical support.

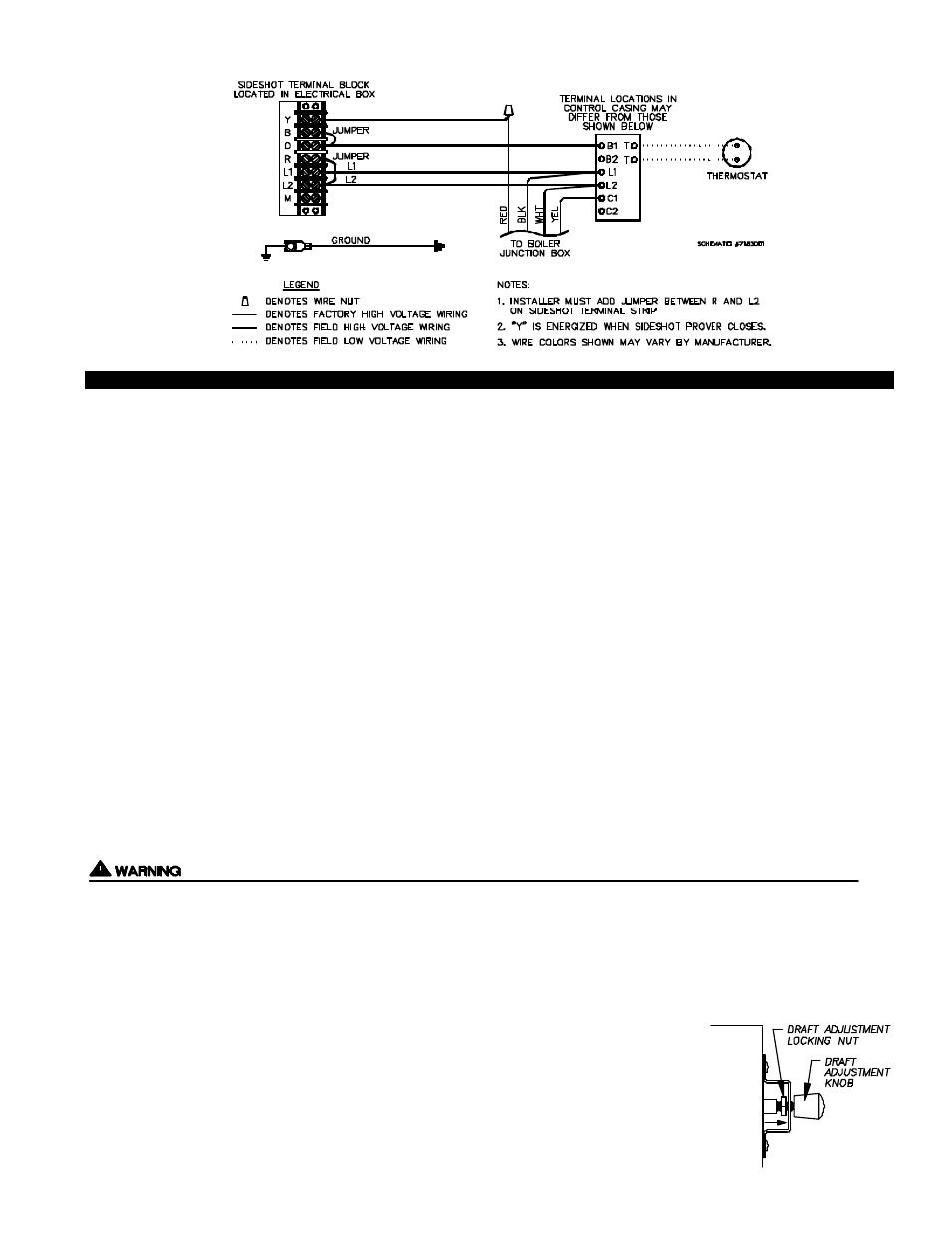

10. Lock down the burner primary air adjustment, the barometric adjustment knob and the SS2 draft

adjustment with the lock nut that is behind the knob bracket, (See Diagram K). Verify the over

fire draft and CO

2

readings have not changed from the earlier values.

DIAGRAM K

SS2 WIRED WITH WEIL-MCLAIN WGO, WTGO AND SGO-W WATER BOILERS

OR AQUASTAT CONTROLLED BURNERS WITH CARLIN 602002 PRIMARY CONTROL