Lubrication, 1. type of oil, 2. lubrication method – Rice Lake Star TSP-700 - Technical Manual User Manual

Page 14: 3. lubrication locations

– 10 –

MAINTENANCE AND LUBRICATION

2.

Lubrication

Lubrication is extremely important for preserving the original performance of the printer over a long period of time.

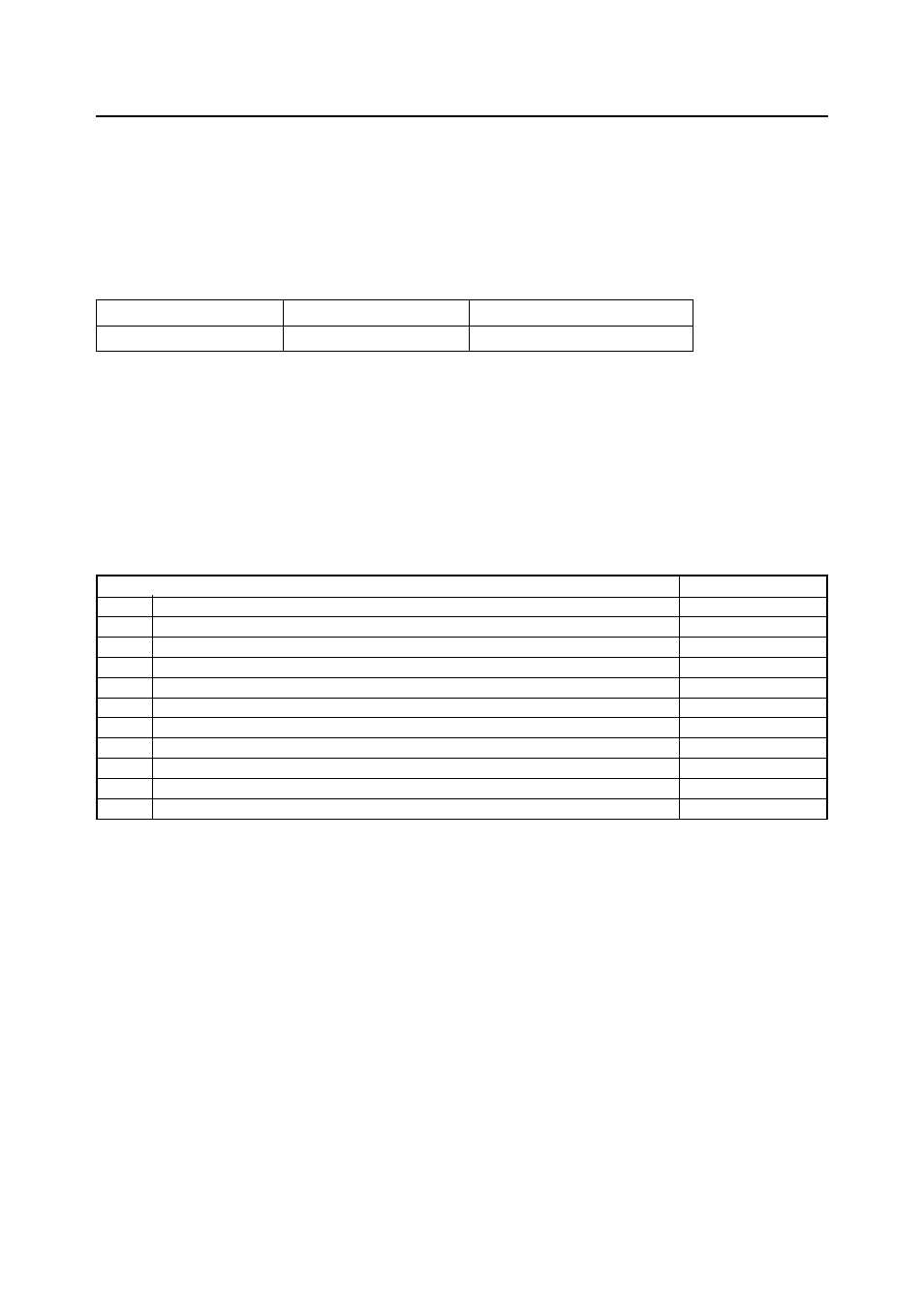

2-1. Type of oil

The type of oil used has a major influence on the performance and durability of the printer.You should pay particular

attention to the cold temperature properties of the oil. We recommend use of the grease and lubrication oils listed below

for this printer.

Type of oil

Product name

Manufacturer

Grease

Molykote EM-30L

Dow Corning Corp.

2-2. Lubrication method

When lubricating during disassembly or assembly operations, be sure to wash and clean the equipment well prior to

lubrication to remove dirt and dust.

Lubricate the equipment at regular intervals of six months or after every one million lines. Be sure to lubricate equipment

after disassembling or replacing parts when oil has been removed by cleaning.

2-3. Lubrication locations

Lubrication locations

Type of oil

1

Rubbing surface of Shaft C and Frame

Molykote EM-30L

2

Rubbing surface of Case stopper and Screw and Frame

Molykote EM-30L

3

Rubbing surface of Gear 24

Ч

0.7 - 55

Ч

0.5 and Frame shaft

Molykote EM-30L

4

Rubbing surface of Gear 40

×

0.5 and Freme shaft

Molykote EM-30L

5

Rubbing surface of Cover B assy and Lock lever

Molykote EM-30L

6

Rubbing surface of Lock lever and Cover open lever

Molykote EM-30L

7

Rubbing surface of Release plate and Cover B assy

Molykote EM-30L

8

Rubbing surface of Release plate and Lock plate

Molykote EM-30L

9

Rubbing surface of Lock plate and Cover B assy

Molykote EM-30L

0

Rubbing surface of Lock plate and Lock plate spring

Molykote EM-30L

A

Rubbing surface of detector holder and near-end detector cover

Molykote EM-30L