Trimming the junction box, Figure 4. signal trim main board, 2railboss calibration guide – Rice Lake RailBoss Rail Scales - Calibration Guide User Manual

Page 2

2

Railboss Calibration Guide

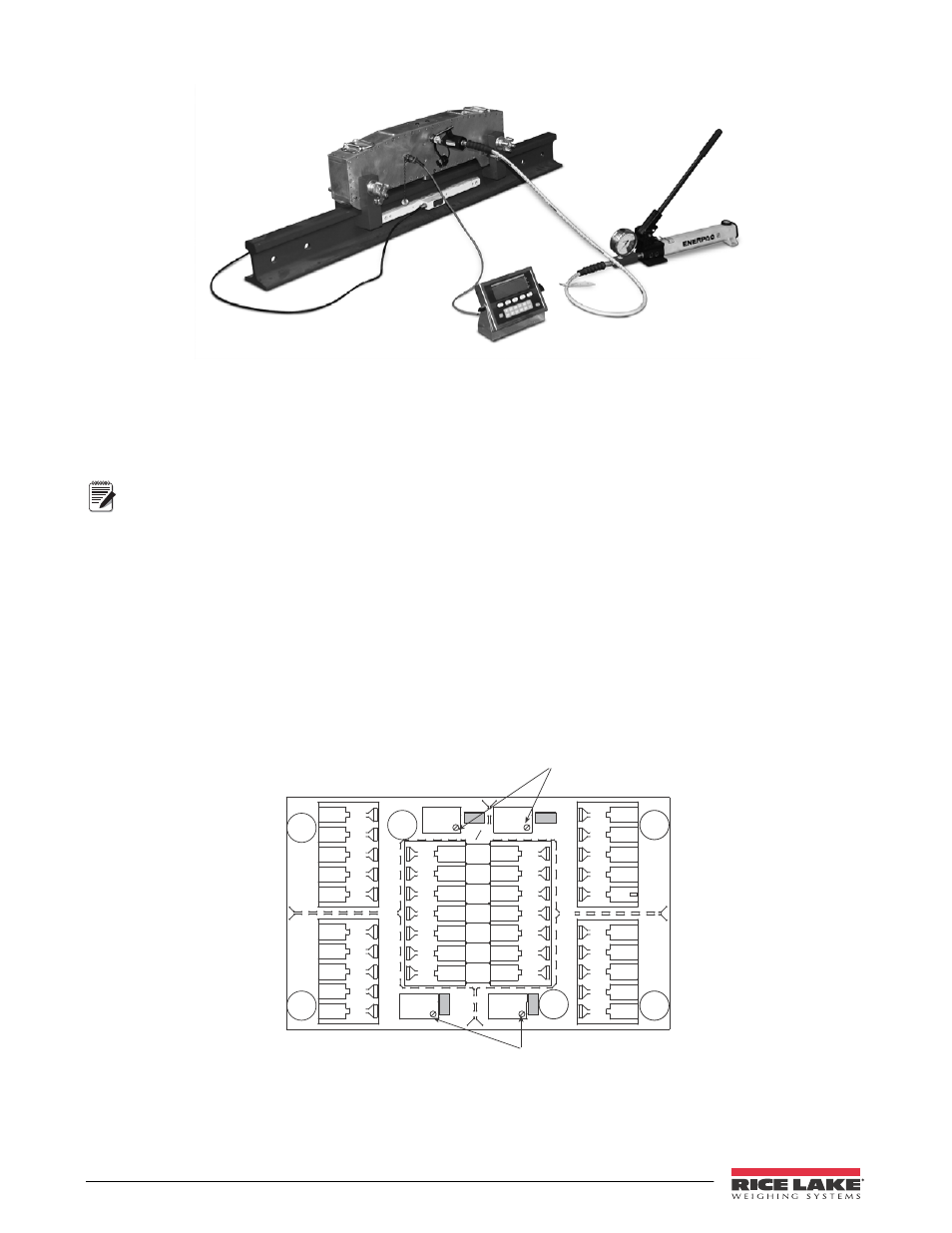

Figure 3. Indicator and Hydraulic Pump Attached to RailBoss Calibrator

4. Engage the pump by closing the release valve located on the side of the pump (turn clockwise).

5. Pump until weight reaches 30,000 lb and release pressure until weight returns to zero.

6. Repeat steps 4 & 5 two more times before attempting to calibrate.

Hydraulic cylinders tend to bleed down at a slow rate.

If weight does not stabilize, repeat step 4-6.

7. Calibrate the indicator to match the scale’s 30,000 lb load (see Section 5.1 of the RailBoss Installation

Manual). If weight is not stable, repeat Step 4.

8. Repeat Steps 1 - 7 on each RailBoss rail.

9. Once calibration is complete on all RailBoss rails, disconnect the hydraulic pump and indicator.

Trimming the Junction Box

Trimming is a process of equalizing the output from multiple individual load cells. If needed, load cell output can

be individually trimmed with potentiometers. Whenever a substantial amount of trim (more than 5% of normal

output), seems necessary to equalize output, check for other possible problems. The best trim is always the least

amount of trim. When all errors except cell mismatch and cable extensions or reductions have been corrected,

continue with trimming.

Figure 4. Signal Trim Main Board

Note

JP4

JP2

PT4

PT3

JP3

PT1

EXP

PT2

JP1

1

CELL4

1

CELL1

1

CELL3

1

CELL2

IND

-EX

-SI

SHD

+SI

+EX

M

R

N

I

-SI

S2C

I

A

G

+EX

+SI

-SI

SHD

-EX

I

S

G

A

L

T

+SI

M

S

I

N

L

T

R

+EX

-EX

-SI

SHD

+SI

+EX

+SI

-EX

-SI

SHD

-EX

SHD

+SE

-SE

+EX

Potentiometers

Jumper Locations

JP1 and JP2

Shaded

Jumper Locations

JP3 and JP4

Shaded

Potentiometers