Rice Lake Datamax-ONeil I-4212e Mark II - Manual User Manual

Page 32

Chapter 3 - Printer Operation

26

3.4.3 Standard Calibration

The Standard Calibration can be performed using the NETira CT Utility (see Section 3.3) or using

the front panel buttons via the printer’s menu, see Section 4.5. Standard Calibration provides

dynamic readings, which can be helpful when using media with small position-critical notches or

marks. Three calibration samples are required:

Empty – with nothing over the sensor;

Gap, Notch, Hole or Mark – with media liner, a notch, hole, or a mark over the sensor; and,

Paper – with the label (and liner, if any) over the sensor.

Calibrate the Media Sensor using the steps below:

The Sensor Calibration menu item is only accessible in the Advanced Menu mode.

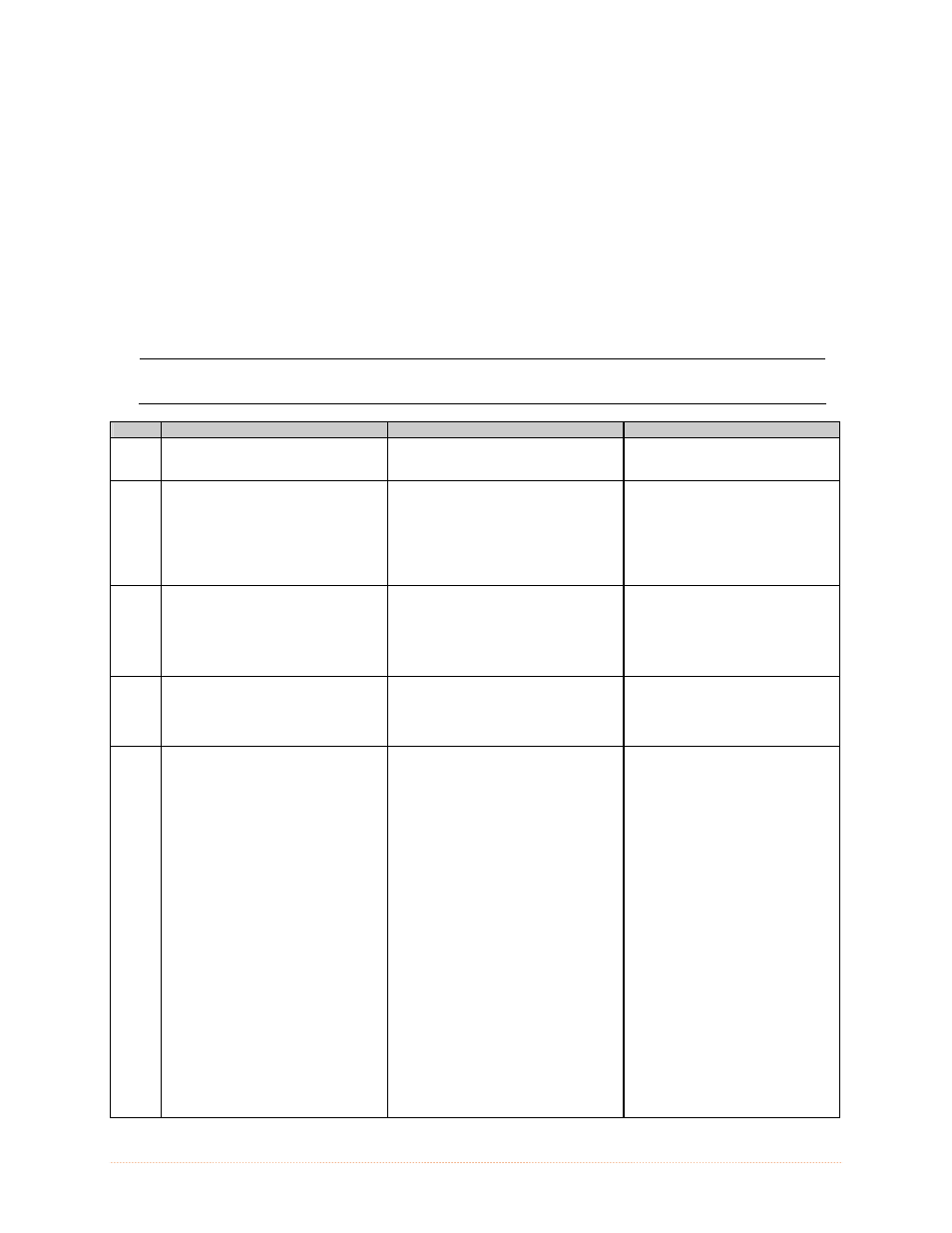

Step

Action

Displayed Message

Comment

A

Turn ON the printer.

READY

Wait briefly for initialization to

complete.

B

Press MENU Button. Make sure

MEDIA SETTINGS is highlighted

and press ENTER.

Then using the DOWN Button,

scroll to SENSOR CALIBRATION.

(Printer Menu)

C

Press ENTER to access SENSOR

CALIBRATION. Then using the

DOWN Button, scroll to PERFORM

CALIBRATION. Press ENTER again

and then press YES to proceed.

PERFORM CALIBRATION

Press NO to abort this procedure.

D

With no media installed, press

ESC.

REMOVE LABEL STOCK

PRESS ESC KEY

Yyy

This sets the empty value, where

“yyy” represents the current

sensor reading.

E

Proceed according to the media

type:

Die-Cut – Remove a label or two

from the liner then install the

media. Position the Media Sensor

under the liner area and press

ESC.

Notched (or Reflective) – Install

media. Position the Media Sensor

under a notch (or black mark) and

press ESC.

Continuous – Press ESC then

proceed to Step F.

For die-cut media:

SCAN BACKING

PRESS ESC KEY

yyy

For Notched/Reflective media:

SCAN MARK

PRESS ESC KEY

yyy

For continuous media:

REMOVE LABEL STOCK

PRESS ESC KEY

Yyy

This sets the gap (or mark)

value, where “yyy” represents

the current sensor reading.

See Section 2.3 for sensor

adjustment instructions.

Do not position a perforation

over the sensor when taking the

sample.

(3) For small notches or

reflective marks, ensure that the

labels exit straight from the

printer.

(4) Unless otherwise noted, do

not move the Media Sensor after

this step.