0 trimming & calibrating, Trimming & calibrating – Rice Lake AX 3040 User Manual

Page 14

10

AX3040 Operator Manual

4.0

Trimming & Calibrating

The Rice Lake AX3040 is delivered with the junction box corner-trimmed. However, once the weigh pads have

been set up, you may want to verify that end weight values on each weigh pad are the same. We suggest you use

25% of the weigh pad capacity for verification. Provided the values are the same, you can perform calibration using

25% of the Rice Lake AX3040 total capacity. Take care to distribute the test weights evenly across the two weigh

pads. Refer to the indicator manual to determine correct calibration procedures.

Trimming Procedure

Trimming is a process of equalizing the output from multiple individual load cells. If needed, load cell output can

be individually trimmed with potentiometers.

Whenever a substantial amount of trim (more than 5% of normal output), seems necessary to equalize output,

check for other possible problems. The best trim is always the least amount of trim. When all errors except cell

mismatch and cable extensions or reductions have been corrected, continue with the trimming.

Use the following steps to properly trim the junction box.

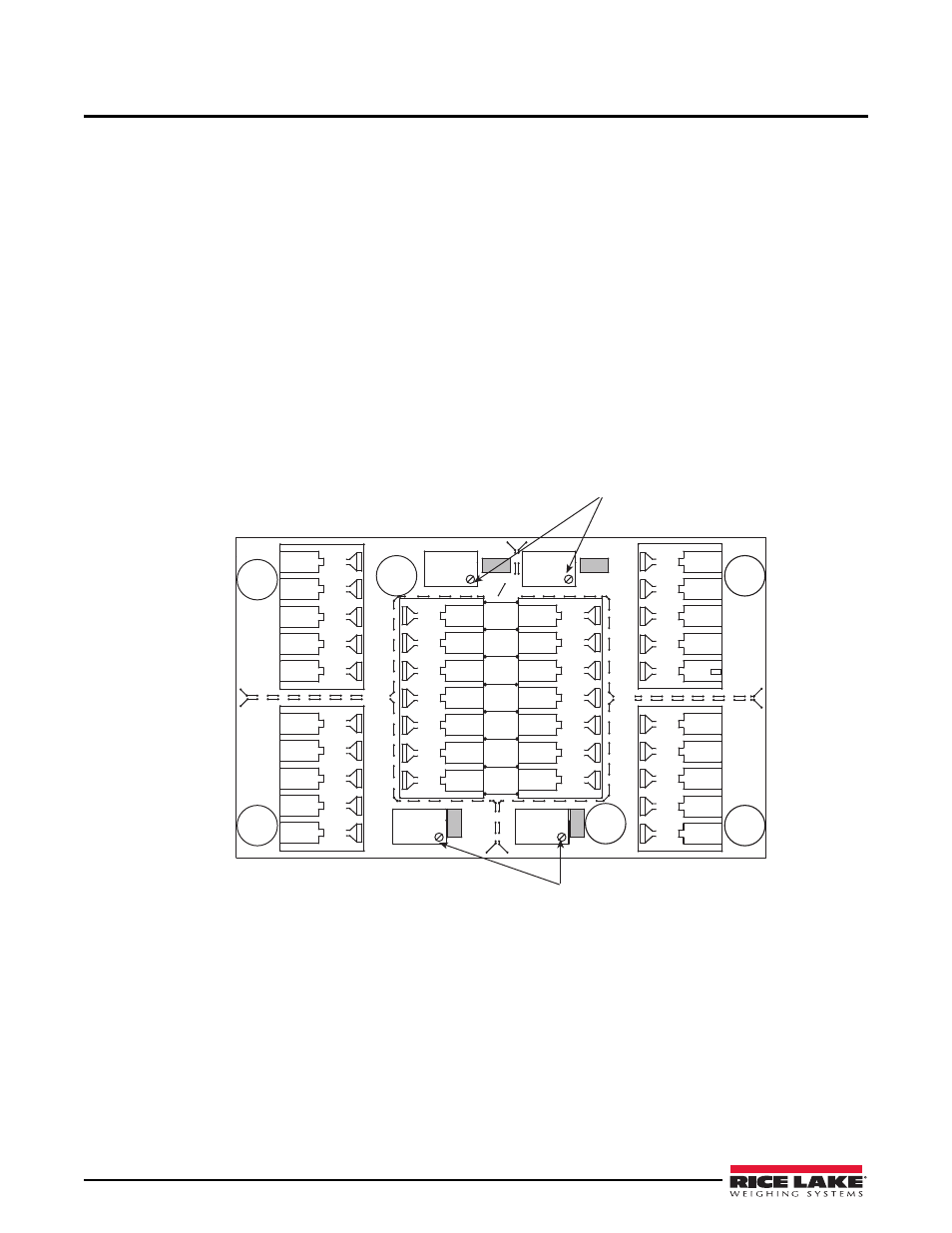

1. Make sure jumpers are in place to enable trimming of the cells corresponding to each load cell. See Figure

4-1 for the location of jumpers JP1, JP2, JP3, and JP4. Note that you need to remove jumpers for any

unused cells.

Set all potentiometers fully clockwise to give maximum signal output from each cell (See Figure 4-1 for

location of potentiometers).

JP4

JP2

PT4

PT3

JP3

PT1

EXP

PT2

JP1

1

CELL4

1

CELL1

1

CELL3

1

CELL2

IND

-EX

-SI

SHD

+SI

+EX

M

R

N

I

-SI

S2C

I

A

G

+EX

+SI

-SI

SHD

-EX

I

S

G

A

L

T

+SI

M

S

I

N

L

T

R

+EX

-EX

-SI

SHD

+SI

+EX

+SI

-EX

-SI

SHD

-EX

SHD

+SE

-SE

+EX

Potentiometers

Jumper Locations

JP1 and JP2

Shaded

Jumper Locations

JP3 and JP4

Shaded

Potentiometers

1

1

Load cells will be

wired in on Cell 1

and Cell 4

Figure 4-1. Potentiometer Locations

2. Zero the indicator and place calibrated test weights over each load cell one at a time. The amount of test

weight to be used will depend on the configuration. Rice Lake Weighing Systems suggest you use 25% of

the weigh pad capacity.

3. Record the value displayed on the indicator after each test weight is placed one at a time on each end

(directly over the load cell) without allowing the weight to overhang the sides. Allow the AX3040 to return

to zero each time to check for friction or other mechanical problems. Select the load cell that has the lowest

value as your reference point. This cell will not be trimmed and will be your reference load cell.

4. Place the same test load over each cell one at a time. Using the corresponding potentiometer, trim each cell

down to equal the reference load cell. As end corrections are somewhat interactive, check all cells again for

repeatability. If necessary, repeat steps 4 and 5.