Test procedure for reduced pressure assembly, Test no. 1 - check valve no. 2, Test no. 2 - shutoff valve no. 2 – FEBCO TK-1 Backflow Preventer Test Kit User Manual

Page 3: Test no. 3 - to test no. 1 check valve, Test no. 4 - pressure differential relief valve

Test Procedure for Reduced

Pressure Assembly

A. All needle valves must be closed on test kit.

B. Open test cock No. 4 and flush test cocks Nos. 1, 2 and 3 on reduced

pressure assembly then close test cock No. 4.

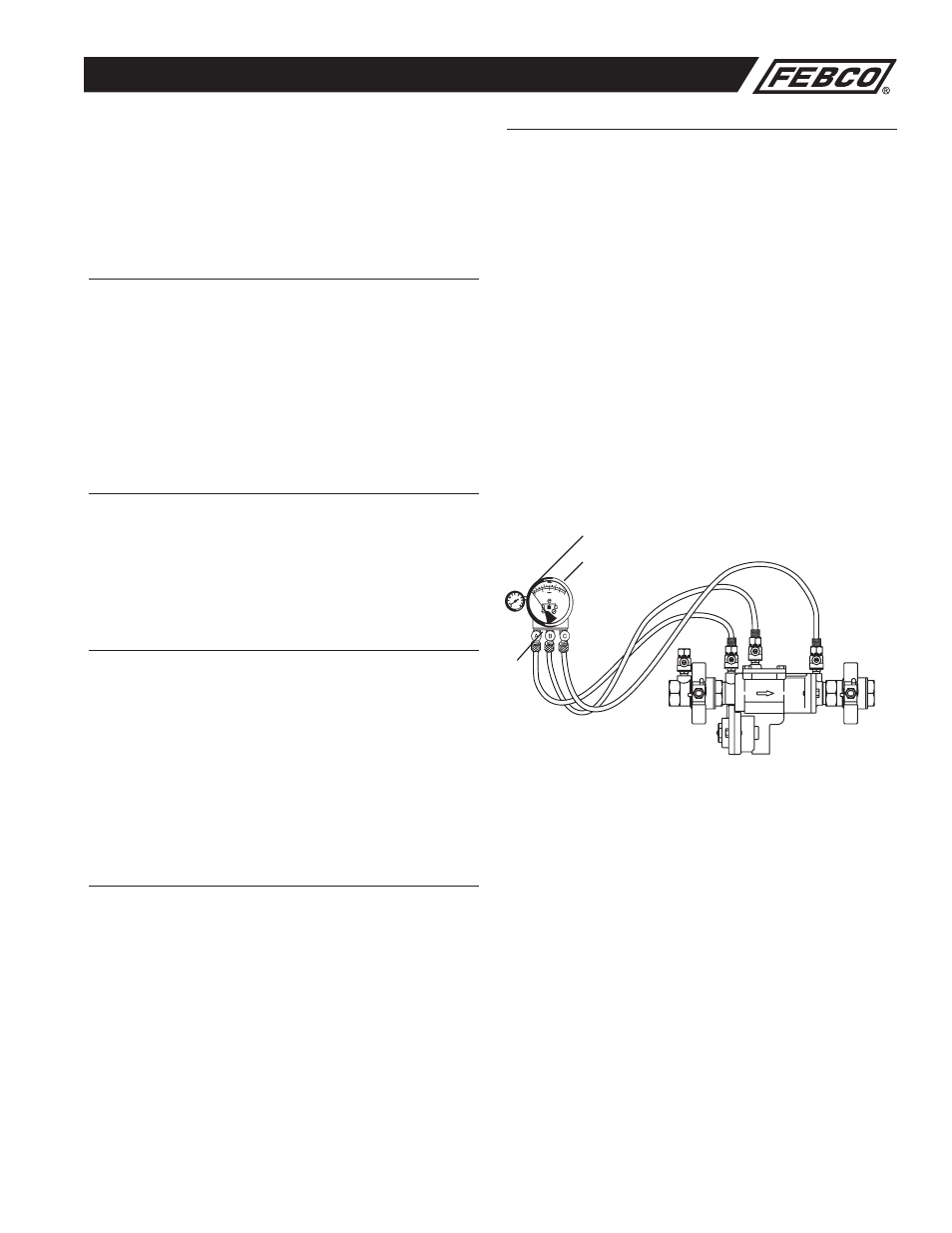

C. Attach hoses as shown. Bleed air from kit, close No. 2 shutoff.

Test No. 1 - Check Valve No. 2

Purpose: To test check valve No. 2 for tightness against reverse flow.

Requirements: Valve must be tight against reverse flow under all pressure

differentials.

Step 1

Slowly open the needle valve "A" high side (red) and "C" bypass

(yellow). Keep the "B" low (blue) closed.

Step 2

Open test cock No. 4. Open test cock No. 2 and test cock No. 3

after opening test cock No. 4.

Step 3

Indicated pressure differential will decrease slightly. If pressure

differential continues to decrease (until the vent opens ) the No.

2 checkvalve is reported as "leaking".

Test No. 2 - Shutoff Valve No. 2

Purpose: To test shutoff valve No. 2 for tightness.

Step 1

After passing Test No. 1, continue to test No. 2 by closing test

cock No. 2.

Step 2

The indicated pressure differential will decrease slightly. If pres-

sure differential continues to decrease (approaching "zero") the

No. 2 shutoff valve is reported to be "leaking".

Note: A leaking No. 2 shutoff will give a false reading in tests No. 3 and 4.

Test No. 3 - To test No. 1 Check Valve

Purpose: To test check valve No. 1 for tightness.

Requirements: Valve must be tight against reverse flow under all pressure

differentials.

Step 1

Close needle valve "A" high side (red) and open test cock No. 2.

Step 2

Close test cock No. 4. Disconnect bypass hose (yellow) at test

cock No. 4.

Step 3

Open needle valve "B" low (blue) and "C" bypass (yellow), bleed-

ing to atmosphere, then closing needle valve "B" (blue) restores

the system to a normal static condition.

Step 4

Observe the pressure differential gauge. If there is a decrease in

the indicated value, the No. 1 check valve is reported as "leaking"

Test No. 4 - Pressure Differential Relief Valve

Purpose: To test operation of pressure differential relief valve.

Requirements: The pressure differential relief valve must operate to main-

tain the "zone" between the two check valves at least 2psi (14 kPa) less

than the supply pressure.

Step 1

Close needle valve "C" bypass (yellow).

Step 2

Open needle valve "A" high side (red).

Step 3

Open needle valve "B" low (blue) very slowly until the differential

gauge needle starts to drop.

Step 4

Hold the valve at this position and observe the gauge reading

at the moment the first discharge is noted from the relief valve.

Record this as the opening differential pressure of the relief

valve. Note: it is important that the differential gauge needle

drops slowly.

Step 5

Close test cocks Nos. 2 and 3. Remove hose from test cocks

Nos. 2 and 3.

Step 6

Use bypass hose (yellow) to relieve pressure from test kit by

opening needle valve "A", "B" and "C" and bleed valves "A" and

“B”.

Step 7

Remove all test equipment and open No. 2 shutoff valve of the

device.

Bleed Valve A

Bleed Valve B

High

(red)

Bypass

(yellow)

3

Low

(blue)

860 Shown