Test procedure for pressure type vacuum breaker, Test no. 1 – air inlet, Test no. 2 – test check valve pressure drop – FEBCO TK-1 Backflow Preventer Test Kit User Manual

Page 2

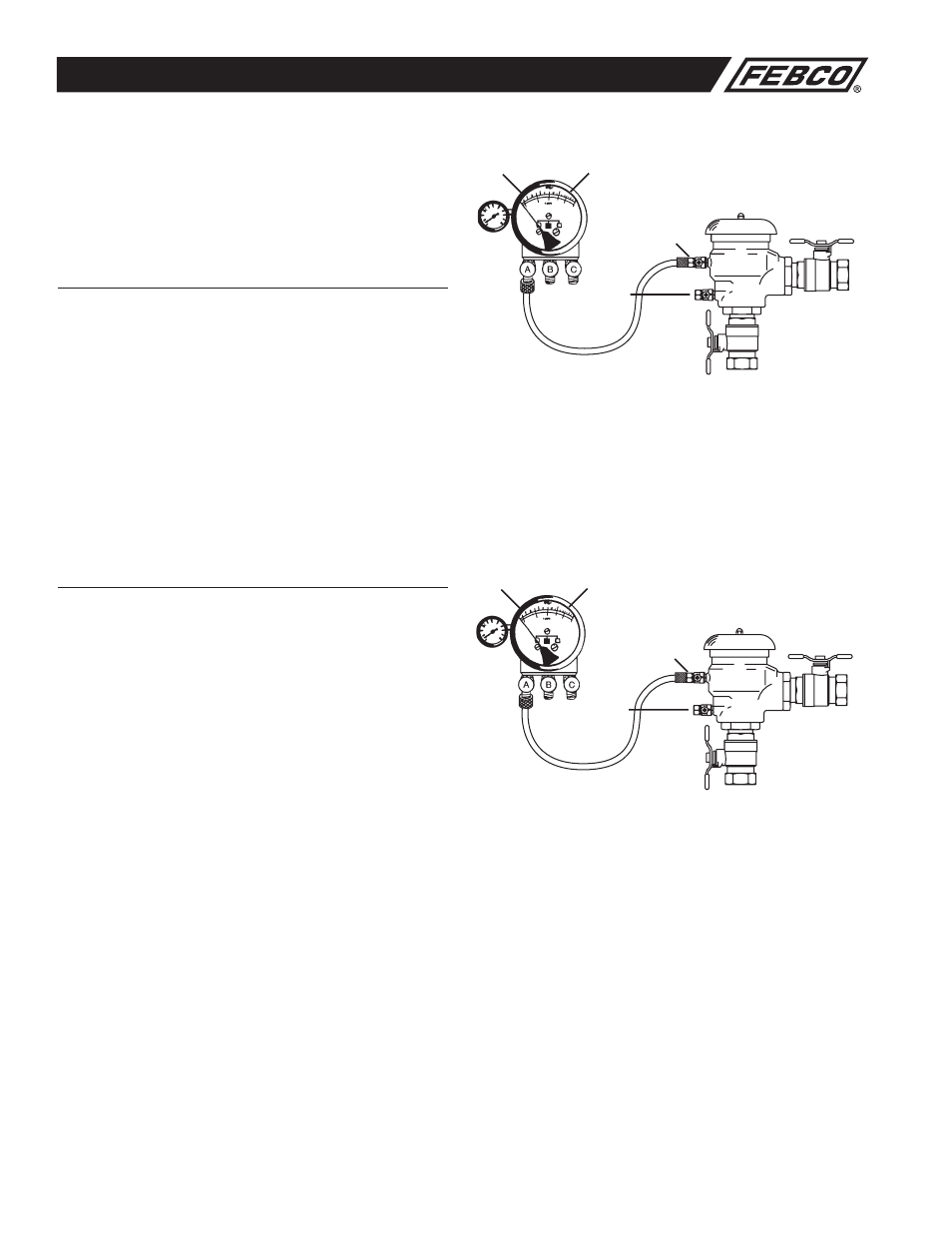

Test No. 1

765 Shown

Test Procedure for Pressure

Type Vacuum Breaker

Note: For both of the following tests the test kit must be held at the same

level as assembly being tested.

A. Before starting test all needle valves and bleed valves must be closed.

B. Flush test cock #2 and #1.

Test No. 1 – Air Inlet

Requirement: Air inlet must start to open when down stream pressure is

1.0psi or above.

Step 1 Remove nut on top of hood and remove hood.

Step 2 Install hose between test cock No. 2 and connection "A" on high

side (red) on test kit.

Step 3

Open test cock No. 2 and needle valve "A" high side (red) on test

kit.

Step 4

Open bleed valve "A" on top of test kit. Bleed air from hose.

Then close bleed valve "A" on top of test kit.

Step 5

Close shutoff valve No. 2 then shutoff valve No. 1.

Step 6

Slowly open needle valve "C" bypass (yellow) just as air inlet

opens. Record differential pressure.

Step 7

Close test cock No. 2 and remove hose.

Step 8

Close needle valve "C" bypass (yellow).

Step 9

Open shutoff valve No. 1.

Test No. 2 – Test Check Valve Pressure Drop

Requirement: Supply pressure drop must be 1.0 PSID or above when

water flow stops from test cock No. 2.

Step 10 Install hose between test cock No. 1 and connection "A" high

side (red) on test kit.

Step 11 Open test cock No. 1 and bleed valve "A" on top of test kit.

Open bleed valve "A" on top of test kit and bleed air from hose.

Shut off bleed valve "A" on top of test kit.

Step 12 Close shutoff valve #1.

Step 13 Open test cock No. 2. When flow of water out of test cock No.

2 stops, the differential reading is the pressure drop record

Step 14 Close test cock No. 1 and test cock No. 2.

Step 15 Replace hood and nut on top of hood. Open shutoff valves Nos.

1 then 2.

2

Test No. 2

765 Shown

Bleed Valve A Bleed Valve B

Test Cock No. 2

Test Cock

Bleed Valve A Bleed Valve B

Test Cock No. 2

Test Cock