FEBCO 860U Reduced Pressure Assemblies with Union End Ball Valves User Manual

English instructions, Installation instructions, Service and maintenance

ENGLISH INSTRUCTIONS

Limited Warranty: FEBCO (the “Company”) warrants each product to be free from defects in material

and workmanship under normal usage for a period of one year from the date of original shipment. In the

event of such defects within the warranty period, the Company will, at its option, replace or recondition

the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY

GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy

described in

the first

paragraph of

this warranty

shall constitute

the sole

and exclusive

remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing

other property which is damaged if this product does not work properly, other costs resulting from labor

charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water

conditions, chemical, or any other circumstances over which the Company has no control. This warranty

shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance

or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow

the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may

not apply

to you.

This

Limited Warranty

gives you

specific legal

rights, and

you may

have other

rights

that vary from State to State. You should consult applicable state laws to determine your rights.

SO

FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT

BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

SHIPMENT.

Garantía limitada:

FEBCO

(en adelante,

“la Compañía”)

garantiza, por

un período

de un

año a

partir de

la fecha

de embarque original, que sus productos están libres de defectos en materiales y mano de obra bajo condiciones

de uso normal. En caso de que se encuentren tales defectos dentro del período de garantía, la Compañía reem-

plazará o reacondicionará, a su elección, el producto sin costo alguno.

LA GARANTÍA AQUÍ ESTIPULADA SE OTORGA EN FORMA EXPRESA Y ES LA ÚNICA GARANTÍA

OTORGADA POR LA COMPAÑÍA EN RELACIÓN CON EL PRODUCTO. LA COMPAÑÍA NO OTORGA NINGUNA

OTRA GARANTÍA, YA SEA EXPRESA O IMPLÍCITA. LA COMPAÑÍA POR LA PRESENTE RENUNCIA

ESPECÍFICAMENTE A TODAS LAS DEMÁS GARANTÍAS, EXPRESAS O IMPLÍCITAS, INCLUYENDO SIN

LIMITACIÓN, LAS GARANTÍAS IMPLÍCITAS DE APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA

UN PROPÓSITO EN PARTICULAR.

La solución descrita en el primer párrafo de esta garantía constituirá la única y exclusiva solución por incum-

plimiento de

garantía, y

la Compañía

no se

hará responsable

por daños

accidentales, especiales

o indirectos,

incluyendo sin limitación, la pérdida de ganancias o el costo de reparación o reemplazo de otra propiedad que

resulte dañada por el mal funcionamiento de este producto, otros costos resultantes por mano de obra, retardos,

vandalismo, negligencia, obstrucciones ocasionadas por materiales extraños, daños debidos a condiciones

adversas del

agua, químicos

o cualquier

otra circunstancia

sobre la

cual la

Compañía no

tenga control.

Esta

garantía no

tendrá validez

en cualquier

caso de

abuso, uso

indebido, aplicación

incorrecta, instalación

inadec-

uada, o mantenimiento adecuado o alteración del producto.

Algunos Estados no permiten limitaciones en la duración de una garantía implícita y algunos Estados no permiten

la exclusión o limitación de daños accidentales o indirectos. Por lo tanto, es posible que las limitaciones anteriores

no sean aplicables en su caso. Esta garantía limitada le da derechos legales específicos; usted podría tener tam

-

bién otros

derechos que

varían según

el Estado.

Usted

debe consultar

las leyes

estatales aplicables

para deter

-

minar sus derechos.

EN LA MEDIDA EN QUE SEA CONGRUENTE CON LAS LEYES ESTATALES APLICABLES,

CUALQUIER GARANTÍA IMPLÍCITA QUE NO SEA RECHAZADA, INCLUYENDO LAS GARANTÍAS IMPLÍCITAS DE

APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN PROPÓSITO EN PARTICULAR, SE LIMITA EN

SU DURACIÓN A UN AÑO A PARTIR DE LA FECHA DEL EMBARQUE ORIGINAL.

Garantie limitée:

FEBCO (la « Société ») garantit que chacun de ses produits est exempt de vice de

matériau et de fabrication dans des conditions normales d’utilisation pour une période d’un an à compter

de la date d’expédition d’origine. Dans l’éventualité où de tels vices se manifesteraient pendant la période

de garantie, la Société, à sa discrétion, remplacera ou reconditionnera le produit sans frais.

LA PRÉSENTE

GARANTIE EST

EXPRESSE ET

REPRÉSENTE LA

SEULE GARANTIE

OFFERTE PAR

LA SOCIÉTÉ POUR CE PRODUIT. LA SOCIÉTÉ N’OFFRE AUCUNE AUTRE GARANTIE, EXPRESSE OU

TACITE. PAR LA PRÉSENTE, LA SOCIÉTÉ REJETTE SPÉCIFIQUEMENT TOUTE AUTRE GARANTIE,

EXPRESSE OU TACITE, NOTAMMENT TOUTE GARANTIE TACITE DE QUALITÉ MARCHANDE OU

D’ADAPTATION À UN BUT PARTICULIER.

Le recours

décrit dans

le premier

paragraphe de

cette garantie

constitue le

seul recours

à toute

violation

de la présente garantie. La Société ne saurait être tenue responsable de tout dommage accessoire, spé-

cial ou indirect, y compris, de façon non limitative : la perte de profits ou le coût afférent à la réparation ou

au remplacement d’autres biens qui seraient endommagés par suite du fonctionnement incorrect dudit

produit ; d’autres coûts résultant de frais de main-d’œuvre, de retards, de vandalisme, de négligence,

d’une obstruction causée par des matériaux étrangers, de dommages causés par une eau impropre,

des produits chimiques ou par tout autre événement échappant au contrôle de la Société.

La présente

garantie est déclarée nulle et non avenue en cas d’usage abusif ou incorrect, d’application, d’installation

ou d’entretien incorrects ou de modification du produit.

Certains États

n’autorisent pas

les limitations

de durée

d’une garantie

tacite ou

l’exclusion ou

la limita

-

tion des dommages accessoires ou indirects. Les limitations susmentionnées peuvent donc ne pas

s’appliquer à vous. Cette garantie

limitée vous donne des droits spécifiques et

il se peut que vous ayez

aussi d’autres

droits qui

varient d’un

État à

l’autre. Veuillez

vous référer

aux lois

applicables de

l’État pour

déterminer vos droits en

la matière.

DANS LA MESURE PERMISE PAR LA LOI APPLICABLE DE L’ÉTAT,

TOUTES LES GARANTIES TACITES NE POUVANT PAS ÊTRE REJETÉES, Y COMPRIS LES GARANTIES

TACITES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN BUT PARTICULIER, SONT LIMITÉES

QUANT À LEUR DURÉE À UN AN À COMPTER DE LA DATE D’EXPÉDITION D’ORIGINE.

You are required to thoroughly read all installation instructions and product safety

information before beginning the installation of this product. FAILURE TO COMPLY

WITH PROPER INSTALLATION AND MAINTENANCE INSTRUCTIONS COULD

RESULT IN PRODUCT FAILURE WHICH CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY AND/OR DEATH. FEBCO is not responsible for damages

resulting from improper installation and/or maintenance.

Local building or plumbing codes may require modifications to the information

provided. You are required to consult the local building and plumbing codes prior

to installation. If this information is not consistent with local building or plumbing

codes, the local codes should be followed.

Need for Periodic Inspection/Maintenance: This product must be tested periodi-

cally in compliance with local codes, but at least once per year or more as service

conditions warrant. Corrosive water conditions, and/or unauthorized adjustments or

repair could render the product ineffective for the service intended. Regular check-

ing and cleaning of the product’s internal components helps ensure maximum life

and proper product function.

Installation Instructions

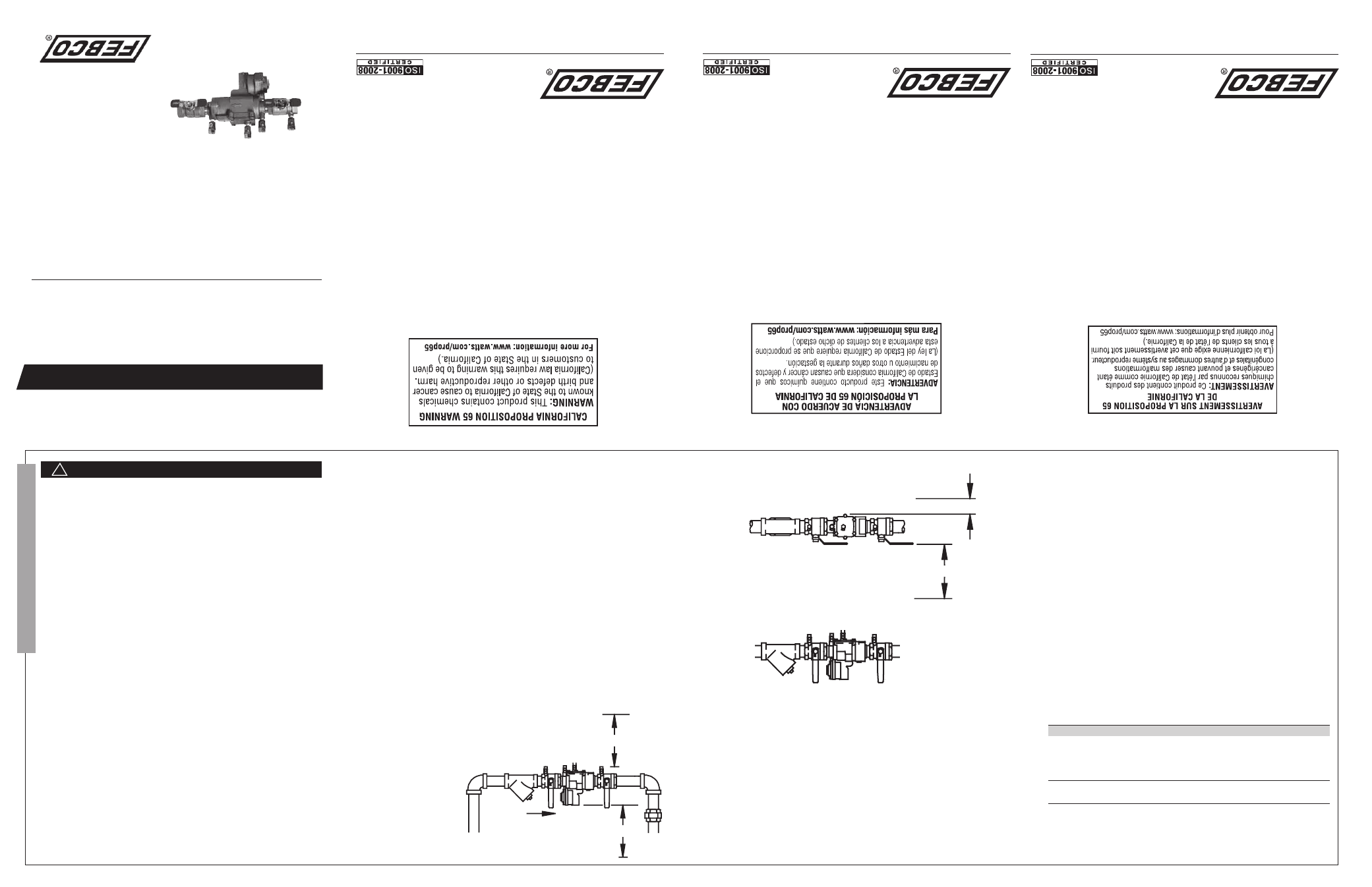

1. These instructions apply to models 860 (RP), 860U (RP), LF860 (RP), and

LF860U (RP) sizes

1

⁄

2

" - 2" (15 - 50mm) only. The valves may be installed only in

the orientation/flow direction as shown.

2. THE VALVE ASSEMBLY MUST BE INSTALLED WHERE RELIEF VALVE

DISCHARGE WILL BE ACCEPTABLE, OR WHERE RELIEF DISCHARGE CAN

BE COMPLETELY DRAINED. The valve assembly must be installed where it is

accessible for periodic testing and maintenance. Clearances shown in the instal-

lation views apply to exterior and interior installations and are only recommenda-

tions. These minimums do not apply to removable protective enclosures. Refer

to local codes for actual requirements in your area.

Note:

The gap drain is not designed to catch the maximum discharge possible

from the relief valve. The installation of FEBCO air gap with the drain line termi-

nating above a floor drain will handle any normal discharge or nuisance spitting

through the relief valve. However, floor drain size may need to be designed to

prevent water damage caused by a catastrophic failure condition. Do not reduce

the size of the drain line from the air gap fitting.

3. PRIOR TO INSTALLING THE VALVE INTO THE LINE, FLUSH THE SUPPLY LINE

OF ALL FOREIGN MATERIAL. Failure to flush the supply line may cause the

Check Valve Disassembly cont.

6. Inspect for debris, damage or fouling of the seat disc. Clean and/or replace parts

as required.

7. Reassemble the valve in the reverse order of disassembly. Ensure the orienta-

tion of the 1st check assembly is positioned so that one (#2) of the four (4) flow

path windows faces down towards the relief valve.

Relief Valve Disassembly

1. Close the outlet shutoff valve, then close the inlet shutoff valve. Bleed residual

pressure from the assembly by opening the #4, #3, and # 2 test cocks in this

sequence.

2. Remove the relief valve cover bolts, cover and relief valve assembly in accor-

dance with the FEBCO maintenance manual.

3. Inspect/clean seat surfaces, seals and diaphragm. Replace worn or damaged

parts as required.

4. Reassemble the relief valve in the reverse order of disassembly.

Test Procedures

FEBCO recommends the use of the appropriate test method presented in the ASSE

Series 5000 manual that is consistent with your local codes.

IS-F-860RPZ 1204

EDP# 980058

© 2012 FEBCO

A Watts W

ater Technologies Company

IS-F-860RPZ 1204

EDP# 980058

© 2012 FEBCO

Una compañía de Watts Water Technologies

IS-F-860RPZ 1204

EDP# 980058

© 2012 FEBCO

Une entreprise de Watts Water Technologies

Typical Installation cont.

Series 860 and LF860

Series 860 y LF860

Séries 860 et LF860

Reduce Pressure Zone Assemblies

Montajes de zona de presión reducida

Disconnecteurs à zone de pression réduite

contrôlable

Size:

1

⁄

2

" - 2" (15-50mm)

Tamaño:

15 a 50 mm (0,5 a 2 pulg.)

Dimensions :

15 à 50 mm (0,5 à 2 po)

IS-F-860RPZ

Installation Instructions

• Instrucciones

de instalación

• Instructions

d’installation

Model 860

USA: Tel: (559) 441-5300 • Fax:

(559) 441-5301 • www.FEBCOonline.com

Canada: Tel: (905) 332-4090 • Fax:

(905) 332-7068 • www.FEBCOonline.ca

EE. UU.: Tel:

(559) 441-5300 • Fax: (559) 441-5301 • www.FEBCOonline.com

Canadá: Tel:

(905) 332-4090 • Fax: (905) 332-7068 • www.FEBCOonline.ca

États-Unis : Tél

: (559) 441-5300 •

Téléc : (559) 441-5301 • www.FEBCOonline.com

Canadá : Tél

: (905) 332-4090 •

Téléc : (905) 332-7068 • www.FEBCOonline.ca

check valves to become fouled and require disassembly and cleaning.

4. After installation SLOWLY fill the assembly with water and bleed air from the body using

the #2, # 3 and # 4 test cocks. Test the valve assembly to ensure correct operation.

NOTE:

All assemblies are tested at the factory for proper operation and leakage. If the

valve does not pass the field test, it is most likely due to a fouled check valve. This is not

covered by the factory warranty. The valve cover must be removed and the check seats

inspected and cleaned. Any damage or improper operation caused by pipeline debris or

improper installation/start-up is not included in the factory warranty.

In case of a possible warranty claim, contact your local supplier or FEBCO

Representative. DO NOT REMOVE THE VALVE ASSEMBLY FROM THE PIPELINE.

5. The assembly must be protected from freezing and excessive pressure increases. Thermal

expansion or water hammer can cause pressure increases. These excessive pressure situ-

ations must be eliminated to protect the valve and system from possible damage.

6. Plastic testcock plugs and tethers are provided (loose in box) for areas that require them.

Service and Maintenance

General

1. Detailed maintenance manuals are available from your local FEBCO representative.

2. Rinse all parts with clean water prior to reassembly.

3. DO NOT USE PIPE DOPE, OIL, GREASE OR SOLVENT ON ANY PARTS unless instruct-

ed to do so.

4. Do not force parts. Parts should fit together freely. Excess force may

cause damage and render the assembly inoperable.

5. Carefully inspect seals and seating surfaces for debris or damage.

6. After servicing, repressurize the assembly and test to ensure

proper operation.

Figure 1

12" Min (300mm)

Flow

12" Min (300mm)

3" Min (75mm)

18" Min (450mm)

HORIZONTAL INSTALLATION 860, LF860, 860U & LF860U

(Top & Side view, shown with strainer)

Figure 2

Troubleshooting

PROBLEM

CAUSE

SOLUTION

1. Continuous relief

a. Debris on check

Disassemble and clean

valve

discharge

seating

surface

b. Debris on relief valve

Disassemble and clean

seating

surfaces

2. Intermittent relief

a. Inlet pressure fluctuations

Eliminate fluctuations

valve discharge

b. Downstream pressure surges Eliminate surges

Check Valve Disassembly

1. Remove cover-bolts using the appropriate size wrench.

2. Remove the spacer between the checks by grasping the flanged end of spacer and pull-

ing straight up.

3. Remove the inlet check assembly by pulling it out from the body bore, in the direction of

flow, until it is completely exposed, then lift out of body.

4. Remove the outlet check assembly by placing the tip of a medium sized flat slotted screw

driver in the slot of the seat and pry the check assembly back until the O-ring is exposed.

Then, using your fingers, pull it out from the body bore until it is completely exposed. Lift

check assembly from the body.

5. Both check assemblies are disassembled and reassembled in the same manner. To disas-

semble, grasp the seat section in one hand and the guide section in the other hand.

Rotate in a counter-clockwise direction (approximately

1

⁄

8

turn) until the two parts disen-

gage.

WARNING

!

Typical Installation