Elecraft XV 432 Assembly Installation Instruction User Manual

Elecraft Accessories communication

Elecraft • www.elecraft.com • 831-662-8345

Elecraft XV432 High Accuracy Crystal Option

Installation Instructions

Revision D, September 1, 2014

Copyright © 2014, Elecraft, Inc. All Rights Reserved

Introduction

The XV432 High Accuracy Option is designed to allow the local oscillator of the XV432 to be set exactly to 404 MHz. This

results in zero frequency offset needed when used with an Elecraft K2 or K3 or the need to manually calculate the actual

frequency when used with other transceivers.

The High Accuracy Option consists of selected crystal and a replacement inductor for L19. The crystal is selected for series

resonance close to the desired frequency and for low series resistance and high Q. Low series resistance and high Q allow the

frequency to be trimmed over an increased range without risk of the oscillator not starting reliably.

Tools Required

You will need a DMM for making voltage checks, an inductor alignment tool (one was supplied with your transverter), a

No. 1 Phillips screwdriver, long nose pliers, a temperature controlled ESD-safe soldering iron with rosin core small diameter

solder and solder wick or desoldering tool to clear the solder pads to replace the inductor.

Observe ESD precautions when working inside your XV432. Wear an ESD wrist strap or touch an

unpainted, metal ground frequently while working.

Installing the New Components

Remove the XV432 top and bottom covers. To remove the bottom cover, first remove the four corner screws

and then remove the two long screws that extend through the heat spreader and are secured by nuts at the ends of the

RF power module on the top of the board. (You don’t need to remove the other two screws. They hold the heat

spreader on the bottom cover.) Be sure you don’t lose the two flat washers that fit between the heat spreader and the

bottom of the PC board. You should have two long screws, two nuts, two lock washers and two flat washers.

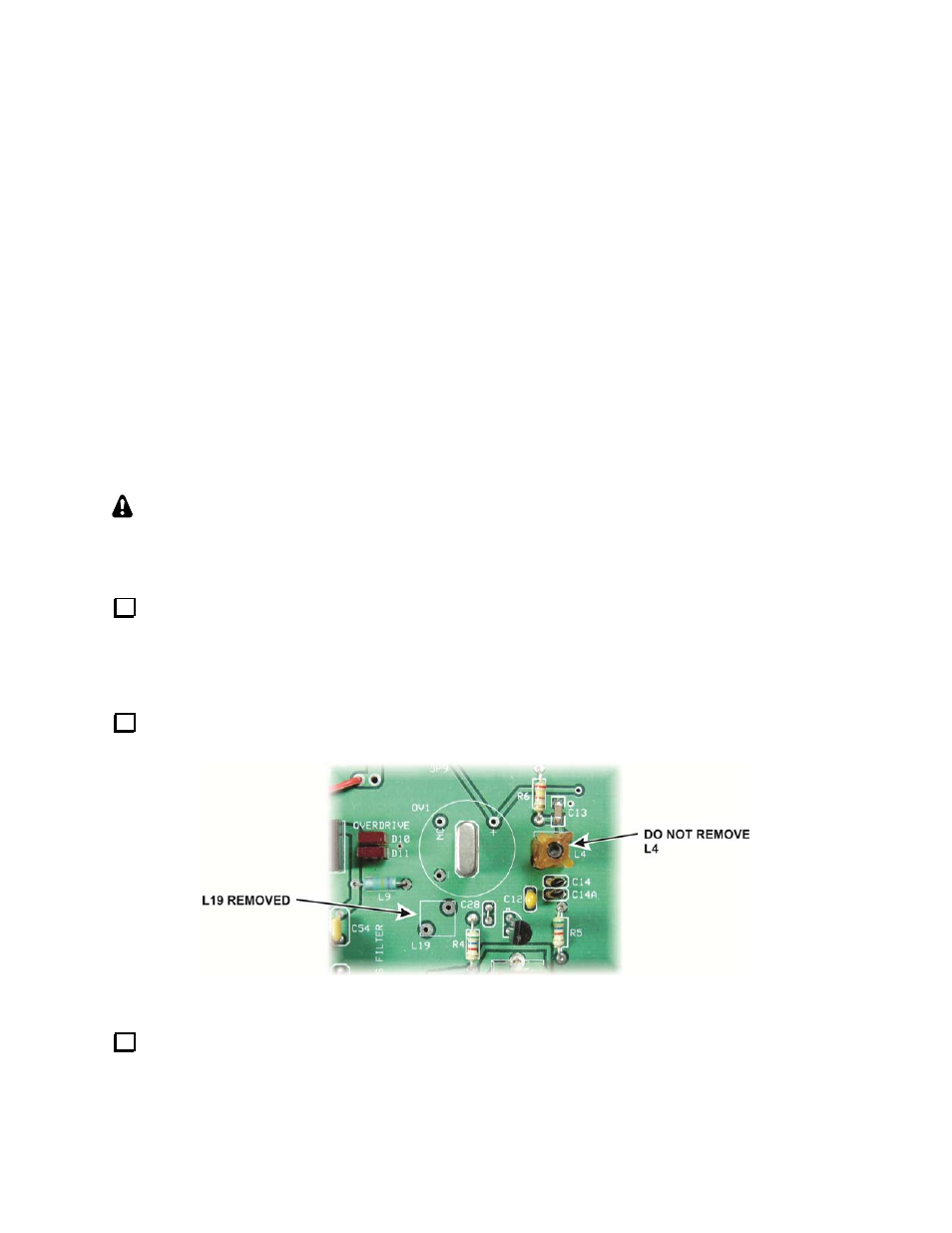

Remove L19 from the circuit board. (See Figure 1). Be sure you remove L19 and not L4 which is also near

the OV1 circle.

Figure 1. L19 Location.

Remove the crystal oven (if so equipped) and the crystal. Replace it with the new crystal. The crystal may be

oriented either way. Be sure the crystal case is sitting directly against the PCB. Do not hold your soldering iron on

the leads more than 2 or 3 seconds maximum. Excessive heat may damage the crystal.