Xi: pressure plate attachment – EFCO S5900 Structural Glazed User Manual

Page 19

EFCO CORPORATION 6/2012 PART NO. Y354

Page 19 of 23

Series 5900 Silicone Structural Glazed Curtain Wall Installation

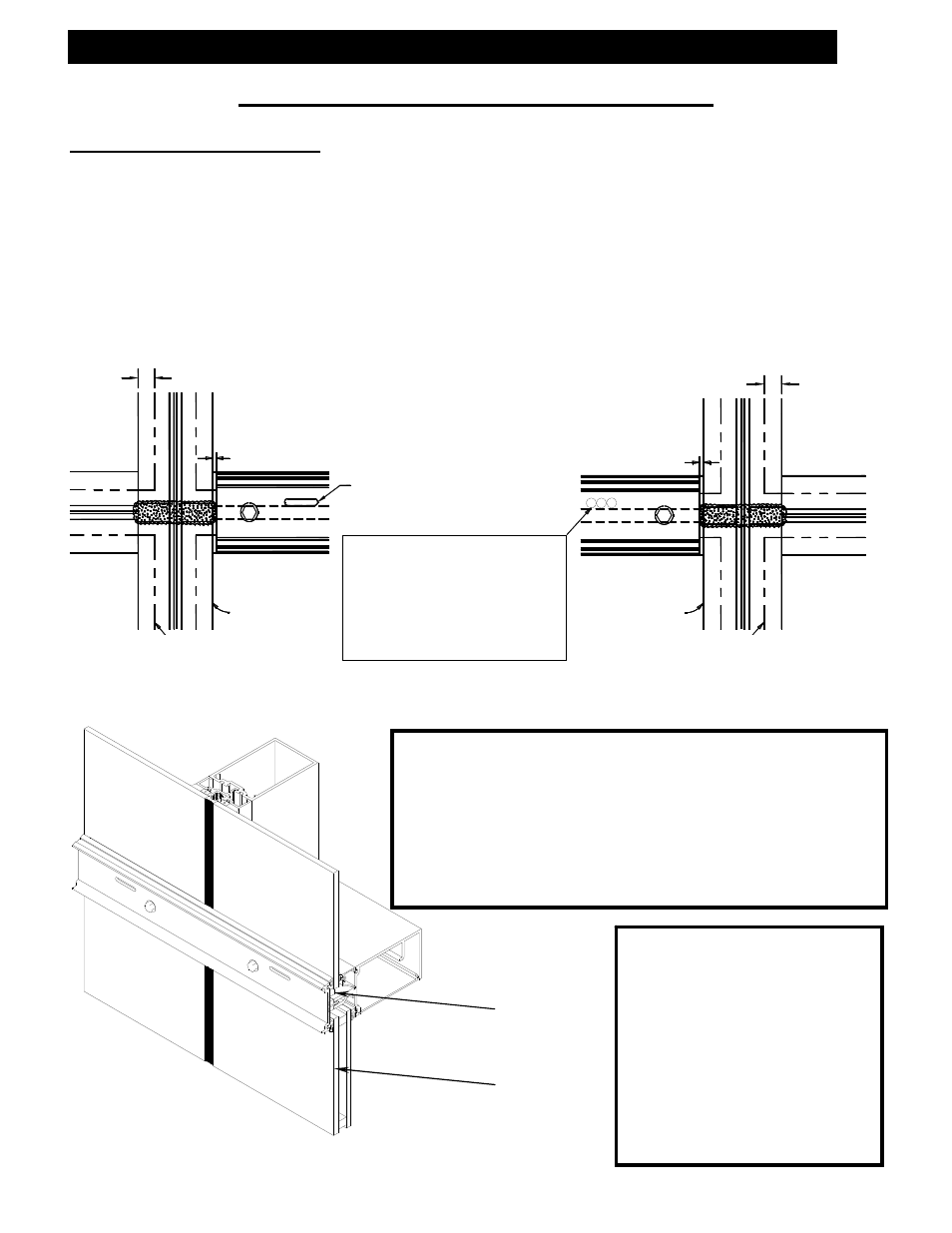

XI: Pressure Plate Attachment

Pressure Plate Attachment

A.)

Attach pressure plates with ¼” X 1” stainless steel hex washer head pressure

plate screws. Typical spacing is 6” on center.

B.)

Torque all pressure plate screws to 80 inch pounds. In cold weather, first torque

all screws to 40 inch pounds. When possible, work from the center outward on

horizontal and from sill upward on verticals. Then torque all screws to 80 inch

pounds after all four sides of the opening have been clamped.

Setting block

Erector Note: Special structural dual seals are required

for structural glazing infill. The insulated glass

may require a structural sealant bead at the

spacer. This will be determined by job specific

information, such as design pressure, infill lite

size, and other pertinent information. Consult the

glass supplier and or manufacturer for specific

application recommendations.

Glass line

Customer / Installer Note:

EFCO setting blocks are

typically 4” in length with

different depths. If the

glazing infill is “NOT BY

EFCO” and glazing sizes are

larger than 40 square feet,

then the glazing details

must be reviewed by the

glazing manufacturer for

proper setting block size.

Edge of Glass

Line of Mullion

3/16” X 1” weep slot

centered 4” off each

end of the pressure

plate.

½” Glass Bite

(typical)

OPTIONAL WEEP HOLES

5/16” dia. weep holes

Drill 3 side by side centered

4” off each end of pressure

plate. Locate C/L of holes

5/32” above top of tongue.

Line of Mullion

Edge of Glass

½” Glass Bite

(typical)

1/8”

1/8”