Vi: glazing preparation – EFCO S5900 Structural Glazed User Manual

Page 14

EFCO CORPORATION 6/2012 PART NO. Y354

Page 14 of 23

Series 5900 Silicone Structural Glazed Curtain Wall Installation

2"

2"

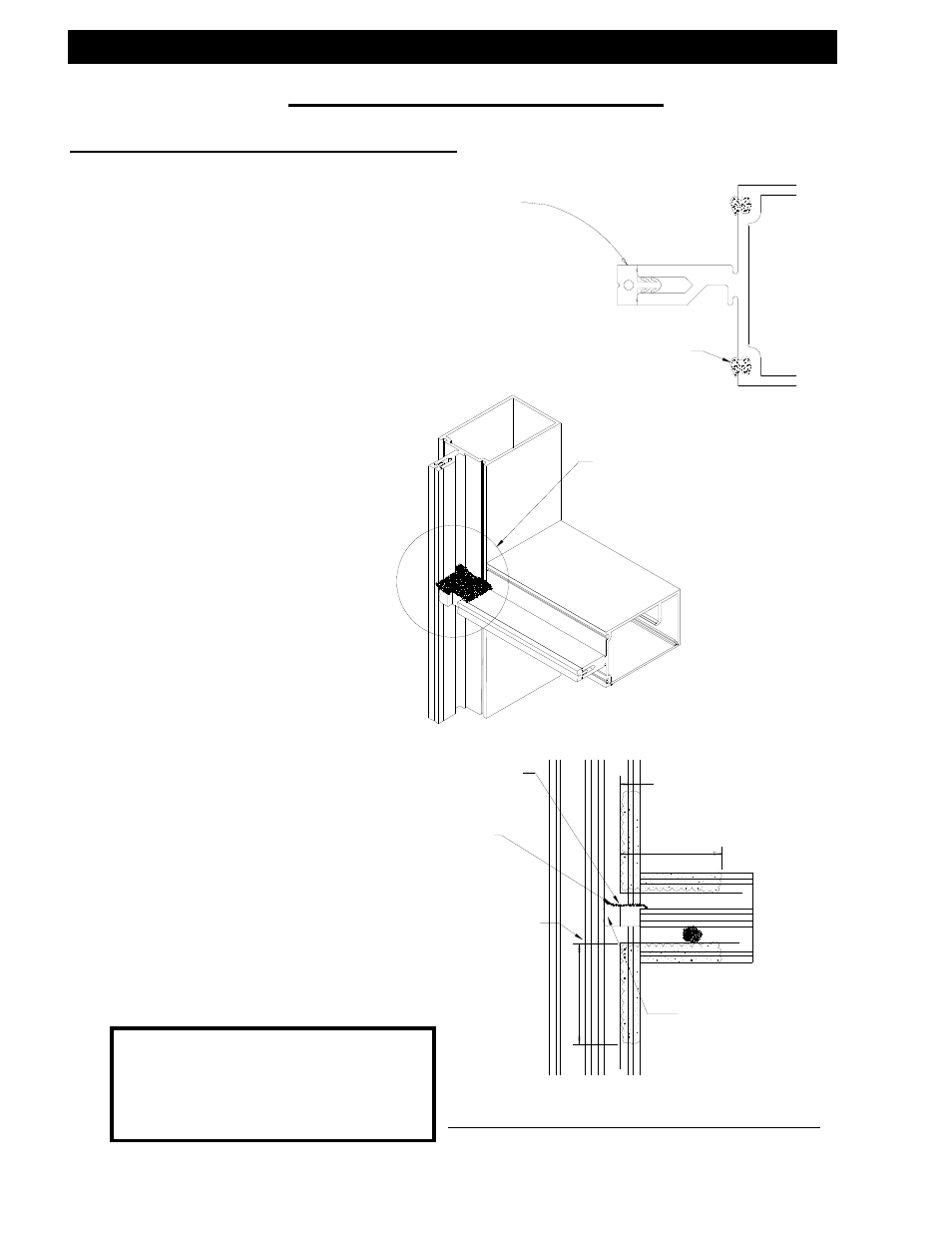

Place and seal the mullion plug. Prior to

installation, apply sealant on all contact

surfaces, and tool off excess sealant to

prevent obstructing the water path.

Seal vertical mullion

gasket raceway 1” prior to

installation of joint plugs.

Seal gasket race 2” in each

direction at all corners with

sealant, making sure that all

fastener heads are sealed.

(Captured system shown,

SSG system similar.)

Closed cell sponge joint plugs

Provide a downward slope with

sealant, without interfering with

the edge of the glass, to allow

for drainage of condensation.

Edge of glass

Apply sealant to the face of

the joint plug prior to the

installation of the pressure

plate. See page #19.

VI: Glazing Preparation

Glazing Preparation At Captured Mullions

A.)

Install the thermal isolator in the vertical

mullion, run continuously, and butt joint

as required.

B.)

Seal vertical mullion raceway 1” long

prior to the installation of the joint

plugs.

C.)

Place and seal the joint plug.

D.)

Tool off all excess sealant.

E.)

Apply sealant to the face

of the joint plug prior to

installation of the pressure

plate. See page #19.

Elevation of Joinery Prior to Setting the Glass

Note: Each daylite opening should

be sealed individually with

gaskets and glazing installed

immediately following with

pressure at the corners.