Welded wind load anchors – EFCO S5500 Outside Glazed User Manual

Page 18

EFCO CORPORATION 6/2012

PART NO. Y550

Series 5500 Outside Glazed Installation Instructions

Section III: Typical Anchorage Methods

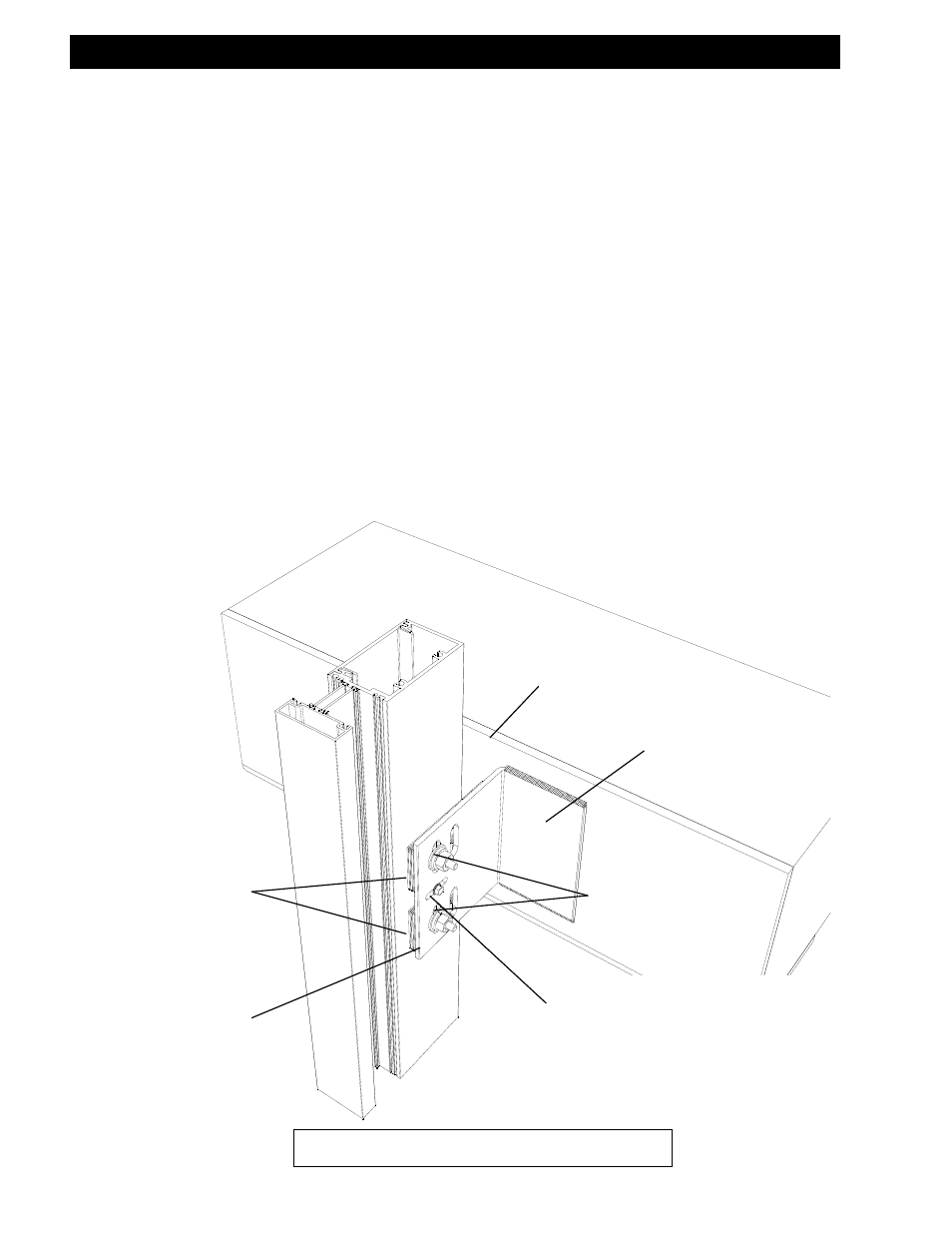

STEP #7 INSTALL FRAME COMPONENTS – WELDED WIND LOAD ANCHORS

For installations with multi-spans, follow applicable notes from step 6. Match drill the mullion

through the

CENTER

of the set of slots in the anchor.

NOTE: The holes must be a minimum of 1” from the back of the mullion in order to clear any steel re-

inforcement located inside the system, as may be required on a job specific basis.

Use a bolt with a flat washer at the bolt head end. At the nut end of the bolt, use a flat washer then a

spring lock washer next to the nut as shown. Shim each bolt as shown.

Important:

The nut must be tightened sufficiently to completely compress the spring lock washer.

Back the nut off a quarter to half turn to allow free movement of the connection. The threads of the

bolts must be “staked”, or Loctite must be used to prevent the nut from loosening from the bolt. Re-

move the temporary alignment screws. Refer to the approved shop drawings for anchor locations,

bolt sizes, welding requirements, and other job specific information.

NOTE: When welding, protect installed

metal and glass from weld splatter.

BUILDING

STRUCTURE

Weld to building structure

per approved shop drawings.

Match drill through

center

of slots.

TEMPORARY ALIGNMENT SCREW (#12 X

1” TEK SCREW) Note: Screw

must

be re-

moved from wind load anchor after bolt

installation to allow free movement.

WELDED WIND LOAD ANCHORS

STEEL ANCHOR PER

SHOP DRAWINGS

HIGH IMPACT

POLYSTYRENE

HORSESHOE SHIMS

AT EACH BOLT