B&M 80885 HAMMER SHIFTER User Manual

Page 2

2

STEP 8.

Install shifter mechanism into ve-

hicle. Slide shifter cable through carpet and

hole in floor. Bolt shifter down using four 1/4"

x 1-1/2" hex bolts and nuts. If required use 1/

4" washers as shims between the shifter

mechanism and floor to level shifter. ROUTE

CABLE AS SHOWN IN FIGURE 5, AVOID

SHARP BENDS WHICH WILL KINK AND DAM-

AGE CABLE. Use cable clamps or tie wraps

to secure the cable housing to chassis to avoid

contact with hot engine or exhaust system.

STEP 9.

Seal the hole where the cable goes

through the floorboards to prevent air or water

leakage. A putty type sealer can be used. For

General Motors vehicles go to Step 10, for

Ford vehicles got to Step 15, For Chrysler

vehicles go to Step 21.

GENERAL MOTORS

STEP 10. If you have not already done so,

remove the stock selector lever nut and selec-

tor lever from the transmission. Discard stock

lever and stock shifter linkage. Install B&M

selector lever in position using stock selector

lever nut, (See figure 6). Torque nut to 23 lb.

ft. The lever should move smoothly from front

to rear with a positive click in each gear

position.

STEP 11. Remove two transmission oil pan

bolts from the middle of the left side of the oil

pan. Install cable bracket in position, (See

figure 6.) The bracket must be installed with

two spacers between the pan and bracket. (If

your transmission is equipped with a cast

aluminum oil pan, these spacers should be

omitted. With a TH-400 with a cast aluminum

oil pan the cable bracket may have to be

modified.) Install the two 5/16-18 x 1.00" bolts

(Metric transmissions use the two 8mm x

25mm bolts) supplied and tighten 12-13 ft.

lbs. Do not overtighten as this can damage

pan gasket.

Note: In some cases possible modifica-

tion to the GM cable bracket might be

required for the 4L80E and 4L85E trans-

missions without the PRNDL switch.

Verify that selector lever does not grind

on cable bracket before moving on to

step 10.

STEP 12. Route the shifter cable according to

figure 5. Avoid kinks and sharp bends and

route the cable away from hot engine or

exhaust parts.

Remove the two rubber boots, one large

nut, and a large lockwasher from the threaded

end of the shifter cable. Slide the end of the

cable into the cable bracket, Install large nut

and lockwasher loosely over end of cable.

Install two rubber boots onto end of cable.

Install the swivel on the threaded end of the

cable and position it in the center of the

threaded portion.

STEP 13. Move the transmission selector le-

ver by hand to full rear position (LOW). Oper-

ate the shifter lever to the low gear position

(ratcheted all the way back). Adjust the large

nuts on the cable so that the swivel will slide

wire must be connected to a source that is hot

when ever the ignition is turned on, since the

shifter indicator will not be visible, even in

daylight, unless it is illuminated. The ground

wire can usually go to one of the bolts that hold

the shifter to the floor. The hot wire will

probably have to go to the instrument panel.

After the wires are lengthened, slide the

indicator in the shifter top plate all the way to

the rear, the end away from the cable connec-

tion. Then tape the two wires to the indicator

cable just ahead of the cable mounting bracket.

Leave a little slack in these wires with the

indicator all the way to the rear. About 3”

further down the cable tape the wires to the

cable again. See figure 4.

Secure the indicator cable bracket to the

shifter mechanism with two #6 x 1/4" sheet

metal screws and #6 washers. (Do not use

longer screws in this position or they will

cause the mechanism to bind.) The eyelet on

the end of the indicator cable is secured to the

cable pin by a supplied small E-Ring, as shown

in figure 3.

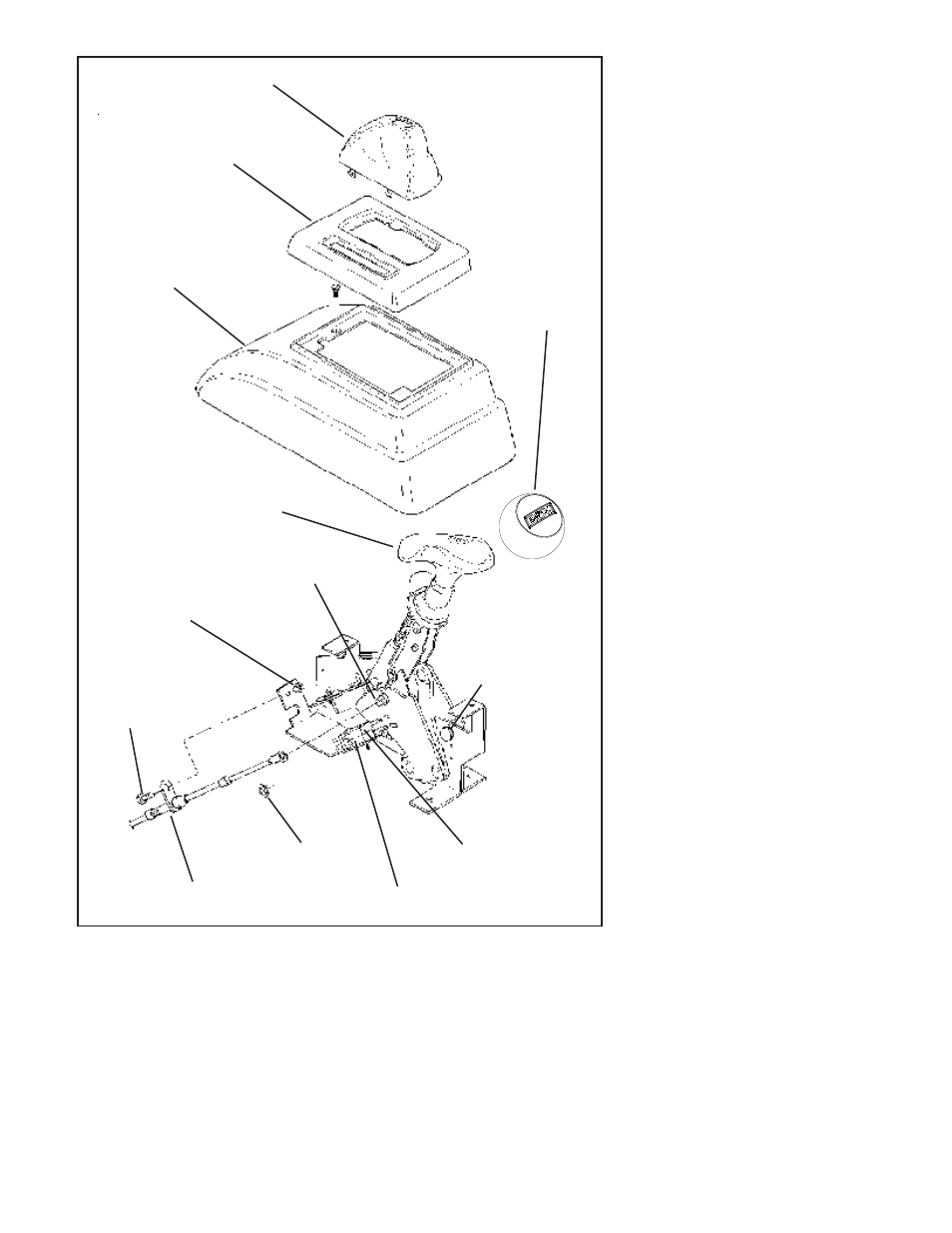

Figure 1

Remove this

blocker

pin and the two e-clips

for GM four speed

transmissions

Cable pin

Boot

Top plate

Tower

1/4" nut

1/4" lockwasher

1/4" x 1/2"

bolt

Cable attaching tab goes on

outside surface of shifter base

E-Ring

Neutral safety

switch

switch

Back-up light

Shifter #80885

Shifter #80887