Stud bolt installation caution, Nut tightening, Nut tightening caution – Tomei Powered VQ35DE MAIN STUD BOLTS User Manual

Page 7

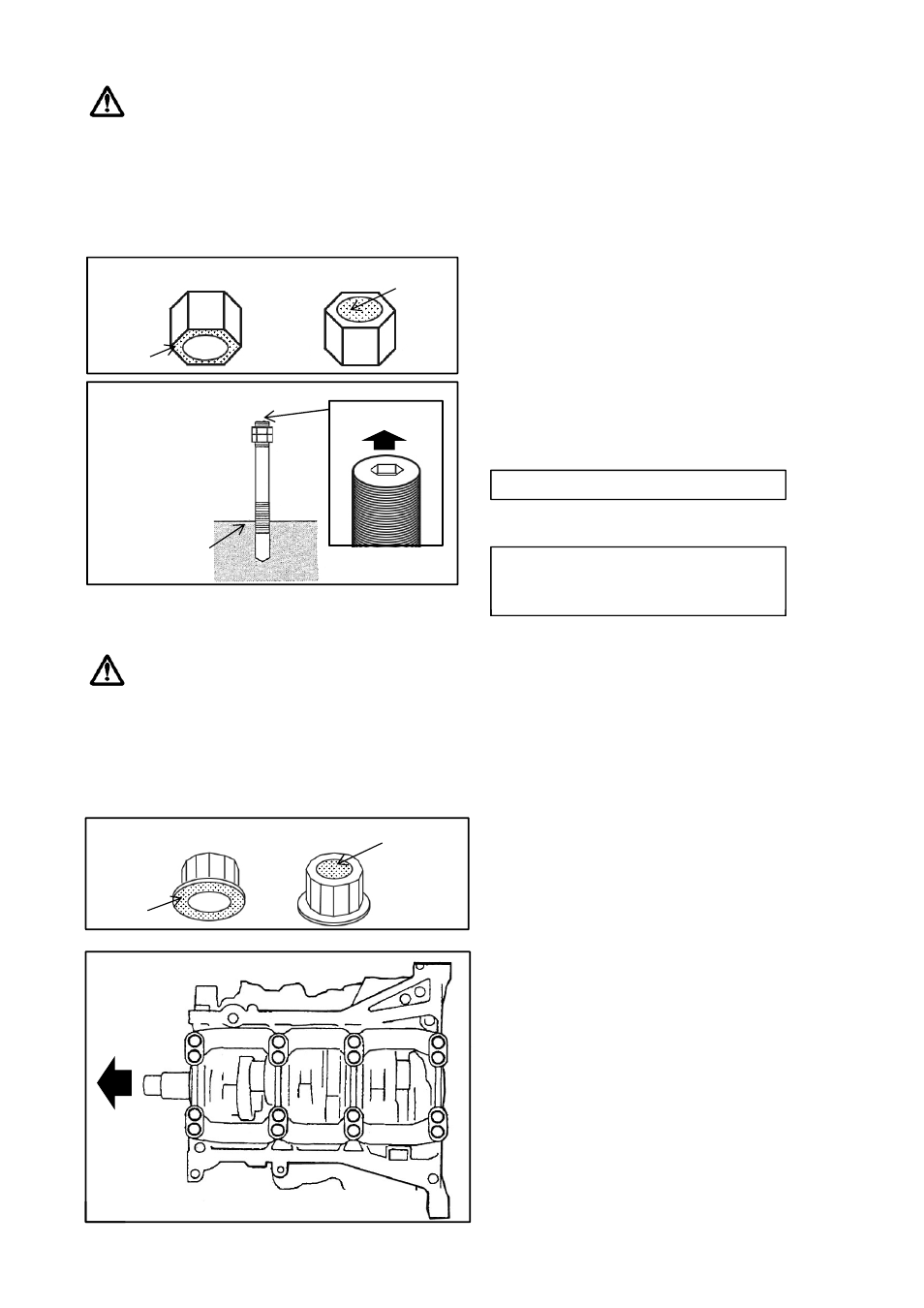

STUD BOLT INSTALLATION

CAUTION

■ Thoroughly clean the Stud Bolt threads on screw holes in the block.

■ The Cylinder Block condition will change when the torque tightening is not done to the recommended specified

values. This affects the Bolts original design function which can lead to complications later.

■ Use a Tap tool to clear and correct all threads in the block. This will assist in securing the correct clamp force.

① Apply the assembly grease on the Nut surface

face & threads, prior to assembly.

② Spread Thread Lock paste on the threads of the

bolt that will be inserted into the block.

③ Fix the nut on the upper side of the Bolt in

the double nut configuration.

④ Tighten with a Torque Wrench.

⑤ Remove the double nut.

NUT TIGHTENING

Torque Settings 1.5kgm (14.7N・m)

The bolt must not move when removing the 2

nuts. If the bolt moves, the whole process will

have to be repeasted.

※ Assembly Nut (6 Sides)

Surface

Thread

Apply Thread

Lock Paste

Use the Double Nut method

Top

7

NUT TIGHTENING

CAUTION

■ Use an Angle Wrench when specifed to.

■ Apply grease to on the contact areas to prior to tightening. This will prevent any damages to the contact

areas, so that the correct torque specs can be obtained.

① Apply the assembly grease on the supplied Nut

surface face & threads, prior to assembly.

(12 sided).

② Follow the numerical order as shown on the left.

(1) Torque to 2.0kg,m (19.6N・m).

(2) Torque to 5.0kgm (49.0N・m).

(3) Torque to 8.2kgm (80.4N・m).

⑭

⑩

⑥

②

④

⑧

⑫

⑬

⑨

⑤

①

③

⑦

⑪

※12 Sides

Thread

Surface

⑮

⑯

FRONT

7