Stud bolt installation caution, Nut tightening caution – Tomei Powered RB26DETT HEAD STUD BOLTS User Manual

Page 8

8

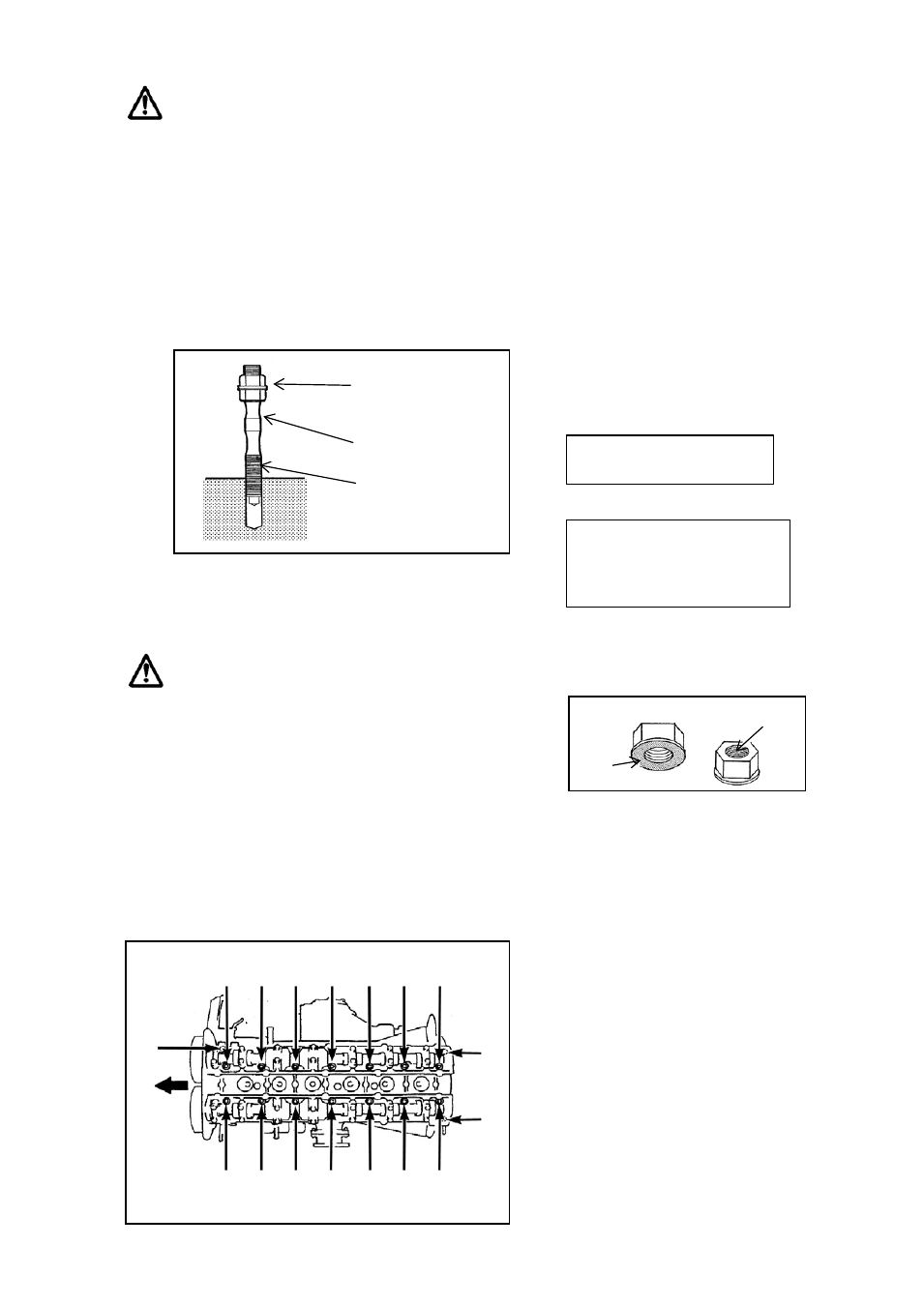

STUD BOLT INSTALLATION

CAUTION

■ Use a tap tool to clear and correct all threads, this will ensure correct clamp force of the bolt with

the Block.

■ Thoroughly clean all stud bolt threads and screw holes. Apply Thread Lock Paste on the Stud Bolt

threads.

■ Be careful when removing the nuts after torquing the stud bolts to the stipulated toque specifications.

If the bolt moves, the whole process will have to be repeated.

■ The Stud Bolt will need to be done up correctly to the stipulated torque requirements. If not, the

Cylinder Block can change and cause the Block to distort. The correct Torque values must be used,

to ensure that the Bolts can function correctly.

■ A 16mm tool is required to remove the nuts.

Use the double nut

① Use the nuts (supplied with this kit)

method with the

as the double nut method for installing

supplied nuts.

the nuts.

② Use a Torque Wrech to torque to the specs below.

STUD BOLT

Apply Thread Lock

Paste

③ Remove the double nuts.

NUT TIGHTENING

CAUTION

■ The Angle Wrench must be used as specified.

Applying Heatproof Lubricant

■ The Heat Proof Lubricant helps with preventing drag on

Nut surface during tightening, so that the stipulated

torque values can be obtained.

■ Try not to mark, scratch or damage the mating face of

the seat surface & the bore grommet of the Metal Gasket during installation.

■ Thoroughly clean the Cylinder Block and Heads surface, to remove any signs of water, oil residue &

unwanted foreign material before installing the Gasket. Give all galleries and passageways a good

spray of high pressure air, to remove any loose unwanted particles.

To be done up in numerical order, as shown

on the left.

① 1st time, torque in sequence 29.4 N・m (3kgm)

with a torque wrench.

② 2nd time, torque in sequence 107.8N・m (11kgm)

with a torque wrench.

③ Losen until the torque reading is 0N・m

with a torque wrench.

④ 1st time, torque in sequence 29.4N・m (3kgm)

with a torque wrench.

⑤ 2nd time, torque in sequence 85°~90°

with an Angle Wrench.

Torque Specs 24.5~29.4N・m

(2.5kgm~3.0kgm)

The bolt must not move when

removing the 2 nuts. If the bolt

moves, the process will have to

be repeated.

Surface

Thread

FRONT

⑮

⑫

⑧

④

②

⑥

⑩

⑭

⑰

⑯

⑬

⑨

⑤

①

③

⑦

⑪