Nut tightening caution, Specifications – Tomei Powered RB26DETT CAM CAP STUDS BOLTS User Manual

Page 7

NUT TIGHTENING

CAUTION

■ Spread engine oil on the journals & cam before installation.

Applying Heatproof Lubricant

■ Do not rotate the Camshaft. It will interfere with the

Valves and Pistons.

■ Apply heatproof lubricant on the nut surface and screw

threads to help prevent drag on the surface when

tightening. This will make it easier to obtain the correct

torque specs.

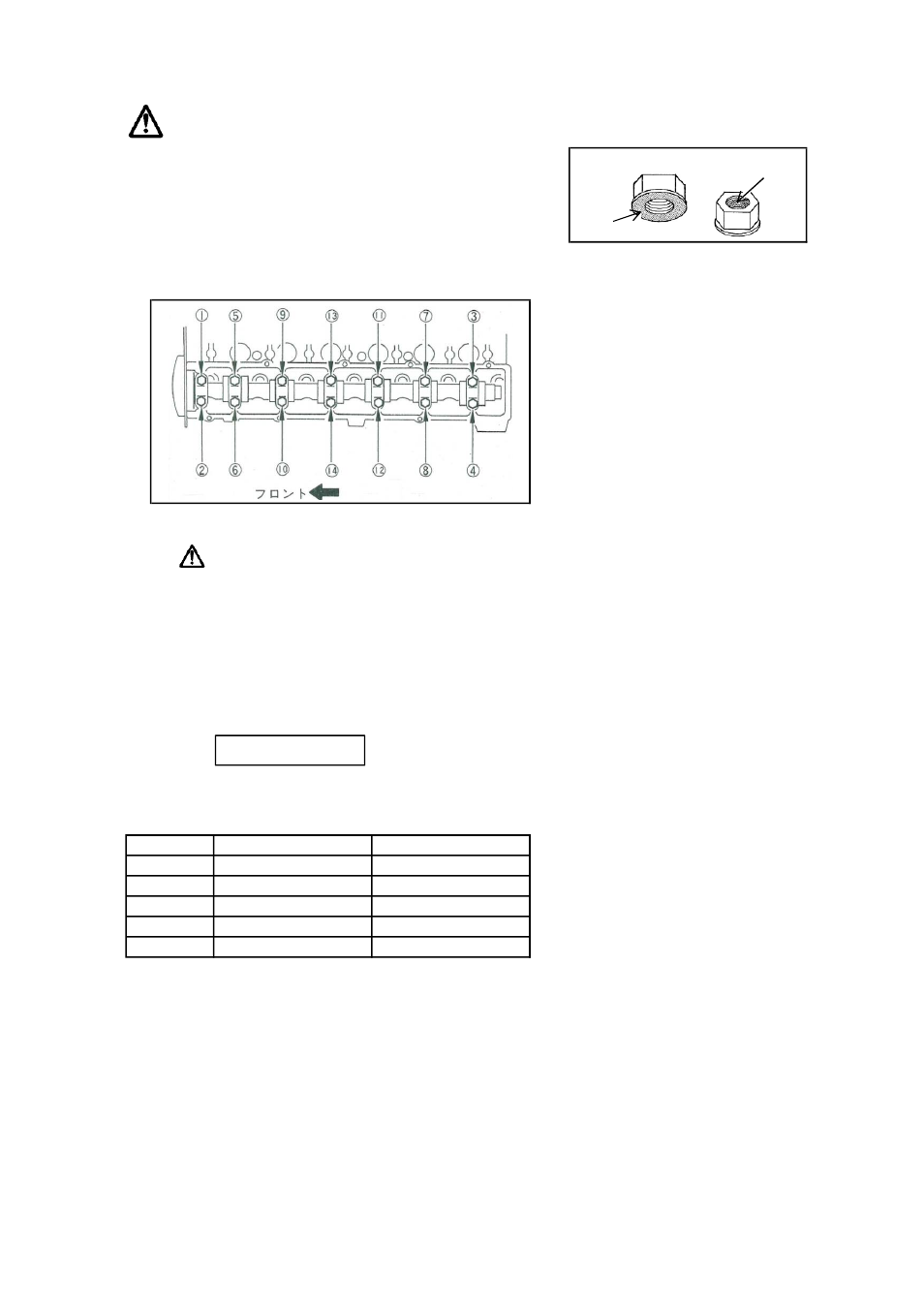

Start tightening the bolts from the left

side of Cylinder No. 1, at TDC on the

compression stroke. Then follow the

numerical order.

① Tighten slowly with care.

When installing the camshaft, start at the end with the cam lobe facing the buckets. Turn

the nut, half turn each time, before going to the next stud. Do the half turn on each nut in

numerical order as shown in the illustration above, 1-14. You must slowly do up each nut

so that the camshaft evenly sinks into the head as horizontal as possible. Time consuming

as it is, this will prevent the camshaft from breaking (which is a common mistake during

Surface

Thread

FRONT

7

as it is, this will prevent the camshaft from breaking (which is a common mistake during

installation).

② Torque the bolts in numerical order.

SPECIFICATIONS

MATERIAL

SIZE

STRENGTH

TREATMENT

WEIGHT

STUD BOLT

NUT

Chromoly (SCM435)

Chromoly (SCM435)

M6 x 1.0 L58.0

M6 x 1.0

12.9T

-

Black Oxidation

Black Oxidation

11.3g (Approx)

3.2g (Approx)

Torque Specs 1.0kgm

7