Ames Fire & Waterworks 5001SS Reduced Pressure Detector Assemblies User Manual

Please read prior to installation, Removing cam-checks

1

Ames Model

4001SS and 5001SS

Reduced Pressure Backflow Preventer

General Installation, Maintenance,

and Parts Information

3" - 6"

1. Before installing any Ames assembly, FLUSH THE LINE THOROUGHLY

to remove all debris, chips and other foreign objects. Failure to do so may make

the assembly inoperable.

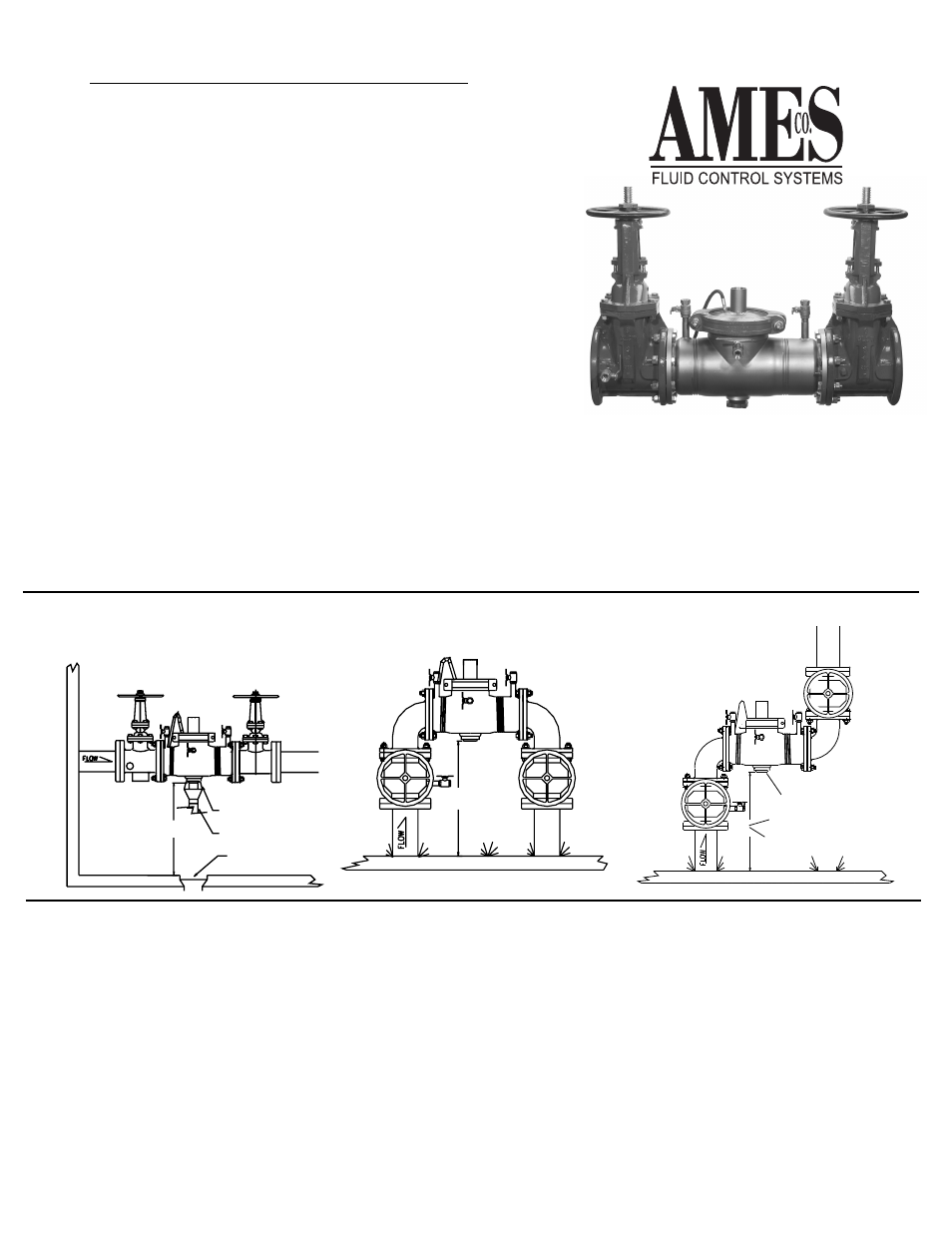

2. The Ames 4001SS and 5001SS Reduced Pressure Backflow Preventers may

be installed in horizontal or vertical positions as shown below. LOCAL WATER

AUTHORITIES MUST APPROVE ALL INSTALLATION CONFIGURATIONS.

3. Backflow preventers must be installed in high-visibility locations in order

to allow for immediate notice of telltale discharge or other malfunction. This

location should also facilitate testing and servicing and protect against

freezing and vandalism.

4. Installing a backflow preventer in a pit or vault is not recommended. Ensure

that all local codes and required safety provisions are met. An air gap below the

relief port must be maintained so as to avoid flooding and submersion of the

assembly, which may lead to a cross connection. Ames recommends installa-

tions indoors or above ground in an insulated enclosure. Normal discharge and

nuisance spitting are accommodated by the use of an Ames air gap fitting and

a fabricated indirect waste line. Adequate floor drain MUST be provided in case

of excessive discharge.

5. IF INSTALLING ON FIRE PROTECTION SYSTEM, BE SURE TO PURGE

AIR FROM FIRE SYSTEM.

Fill system slowly with all inspector's test valves open. Additional venting of air

may be required.

6. The flange gasket bolts for the gate valves shall be retightened during

installation as the bolts may have loosened due to shipping.

Please Read Prior to Installation:

Place yourself so that the water flow through the valve is left to right.

1. Shut down water system and lock out system if possible. Slowly open all ball valves to relieve air and water pressure. After

pressure is relieved, loosen bolts on groove coupler and remove groove coupler and cover plate from valve body.

2. Remove #1 Cam-check Assembly. Do not use Cam Arm as a handle to unscrew Cam-Check. Insert lid bolts in 1st check

seat ring (see fig. 1), insert a long screwdriver or pry bar between lid bolts. Gently apply pressure against the bolts and turn seat

assembly counter clockwise moving bolts hole to hole to maintain turning leverage (two additional bolts will eliminate need to

move lid bolts from hole to hole). Finish unscrewing by hand and remove through top access port. Unscrew #2 Cam-Check

(turn counter-clock wise) by placing a long screwdriver across lid bolts inserted in holes located in the 2nd check seat ring,

similar in method used to remove 1st check and applying pressure to loosen #2 Cam-Check. Finish unscrewing by hand.

3. To clean Cam-Check, locate the Cam Arm opening stud on the outlet flange of the valve assembly. Slide the Cam Arm over

the stud with the check threads facing downward (fig. 2). Tighten a 1/4" nut on stud to secure cam bar. Slowly pull the assembly

outward to open check allowing exposure of the seat and clapper contact area for cleaning. The assembly may be locked open

by aligning the holes in the cam bar and hinge arms and inserting a rod (fig. 4).

12" MIN

36" MAX

RELIEF VALVE

VENT

AIR GAP

DRAIN CONNECTION

FLOOR DRAIN

TO FLOOR DRAIN

12" MIN

36" MAX

INDOOR INSTALLATION

HORIZONTAL INSTALLATION

12" MIN

36" MAX

OUTDOOR INSTALLATION

REMOVING CAM-CHECKS

RP/IS-A-4001SS/5001SS