Installation guidelines – Ames Fire & Waterworks 400B Bronze Reduced Pressure Zone Assemblies User Manual

Page 3

3

Installation Guidelines

WARNING

!

Do not allow the drain line to empty directly into a drainage ditch,

sewer system, or sump.

NOTICE

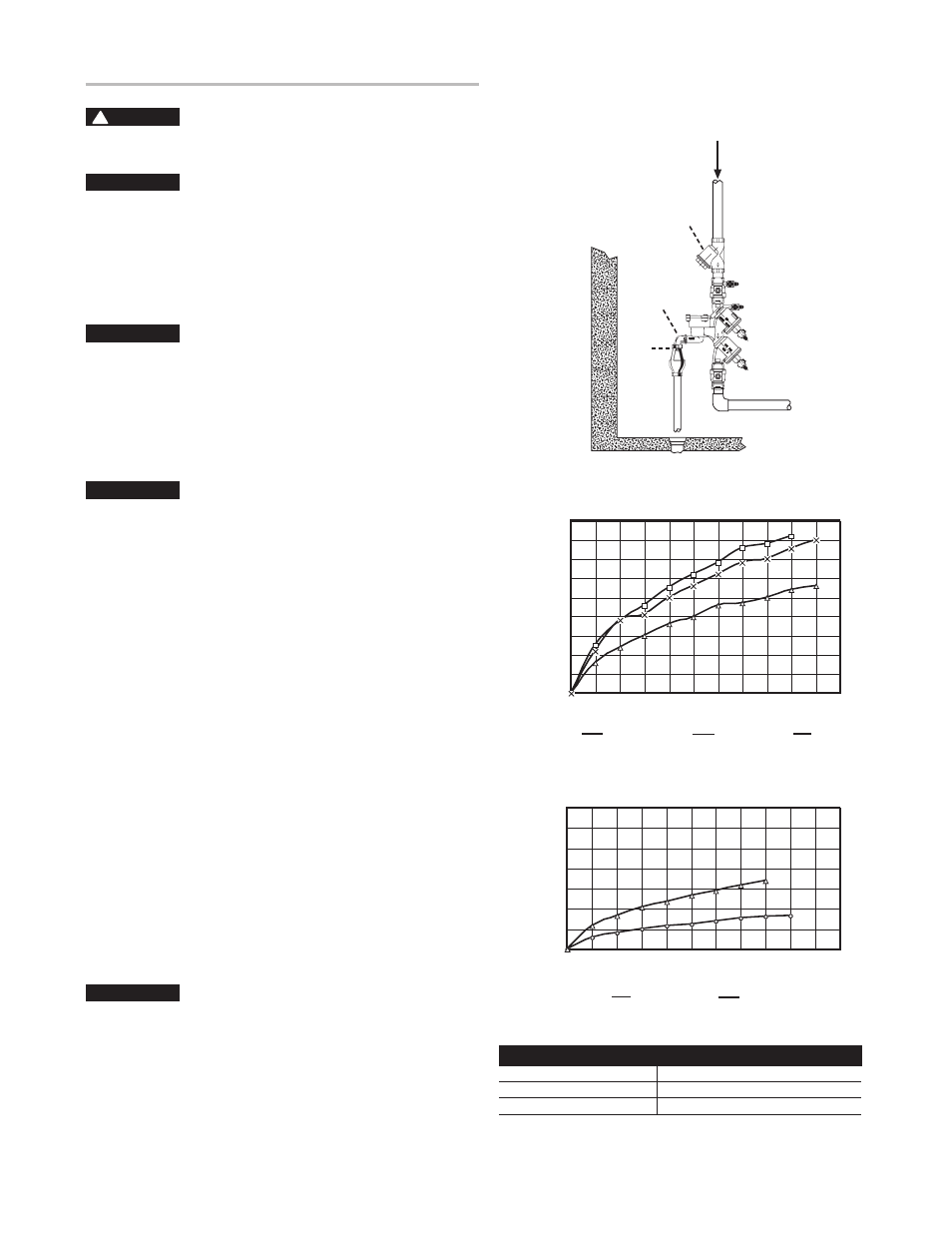

Relief Valve Discharge Rates

The Series 400B air gap and drain line terminating above a floor

drain can accommodate any moderate discharge or nuisance

spitting through the relief valve. However, to prevent water

damage in the case of a catastrophic failure, you may need

to design the floor drain size to accommodate the increased

discharge. Refer to Figure 1 for maximum relief valve discharge

rates, size, and capacity of typical floor drains.

NOTICE

DO NOT reduce the size of the drain line from the air gap fitting.

The drain line must remain at full line size.

E. After initial installation of the Series 400B, a discharge from the

relief valve may occur due to dirt and pipe compounds. This

may be due to inadequate initial flushing of the pipe lines. If

flushing the valve does not clear the unit, remove the first check

valve and clean thoroughly, using the procedures in “Servicing

First & Second Check Valves” on page 5.

NOTICE

Periodic relief valve discharge may occur on dead end service

applications, such as boiler feed lines or cooling tower makeup

lines. This may be due to fluctuating supply pressure during

a static or no flow condition. To avoid this discharge, install a

spring-loaded, rubber seated check valve ahead of the backflow

assembly.

F. It is recommended that you not place the Series 400B in a pit

or at a depth below the ground level, unless absolutely neces-

sary. If an installation requires below ground level installation, a

modified pit installation is recommended, as well as the approval

of local codes. In such cases, provisions should be made to

always vent the drain line above the flood level. In the case of a

pit drain, ensure an adequate air gap exists between the bottom

of the drain line and the bottom of the pit.

G. It is recommended that periodic inspection of the Series 400B

be done to check for any discharge from the relief valve. This

discharge is a visual indication that the valve needs cleaning or

repair. In addition, it is recommended that periodic testing of

the valve be done in compliance with local codes to ensure its

proper operation.

The relief vent discharges water during no-flow periods when:

(1) the first check valve is fouled; or

(2) the inlet pressure to the check valve drops sufficiently due to

upstream pressure fluctuations. This then affects the required

operating differential between the inlet pressure and the re-

duced pressure zone; or

(3) the second check is fouled during emergency backflow or

resulting from a water hammer condition.

NOTICE

When installing the Series 400B on fire prevention systems,

special considerations are required.

Fire Protection System Installations: The National Fire Protection

Agency (NFPA) Guidelines require a confirming flow test be

conducted by a certified tester whenever a “main line” valve is

installed, such as a shutoff valve or a backflow preventer.

1/2"

3/4" M2

1" M2

45

40

35

30

25

20

15

10

5

0

0 10 20 30 40 50 60 70 80 90 100

150

Flow Rate gpm

Flow Rate gpm

Zone Pressure psi

0 10 20 30 40 50 60 70 80 90 100

150

Zone Pressure psi

1

⁄

4

" – 1" (8 – 25mm) 400B

400B

Vertical Flow Down

1

1

⁄

4

" – 2" (32 – 50mm) 400B

350

300

250

200

150

100

50

0

Floor Drain

Air

Gap

Elbow

Strainer

Í

1

⁄

4

"–

1

⁄

2

"

c

3

⁄

4

"

X 1"

(8 – 15mm)

(20mm)

(25mm)

0 1

1

⁄

4

"–1

1

⁄

2

" Í 2"

(32 – 40mm) (50mm)

Figure 1

TypicAl FlOw RATES AS SizED By FlOOR DRAin MAnuFAcTuRERS:

2" (50 mm) 55 GPM

5" (125 mm) 350 GPM

3" (80 mm) 112 GPM

6" (150 mm) 450 GPM

4" (100 mm) 170 GPM

8" (200 mm) 760 GPM