Installation – Baumer Flex Bar 3431 User Manual

Page 2

Page 2

Design and specifi cations subject to change without notice

Installation Manual 5850-016

www.baumerprocess.com

Unpacking the transmitter

If the transmitter is visibly damaged, it should not be put into operation.

Installation procedure

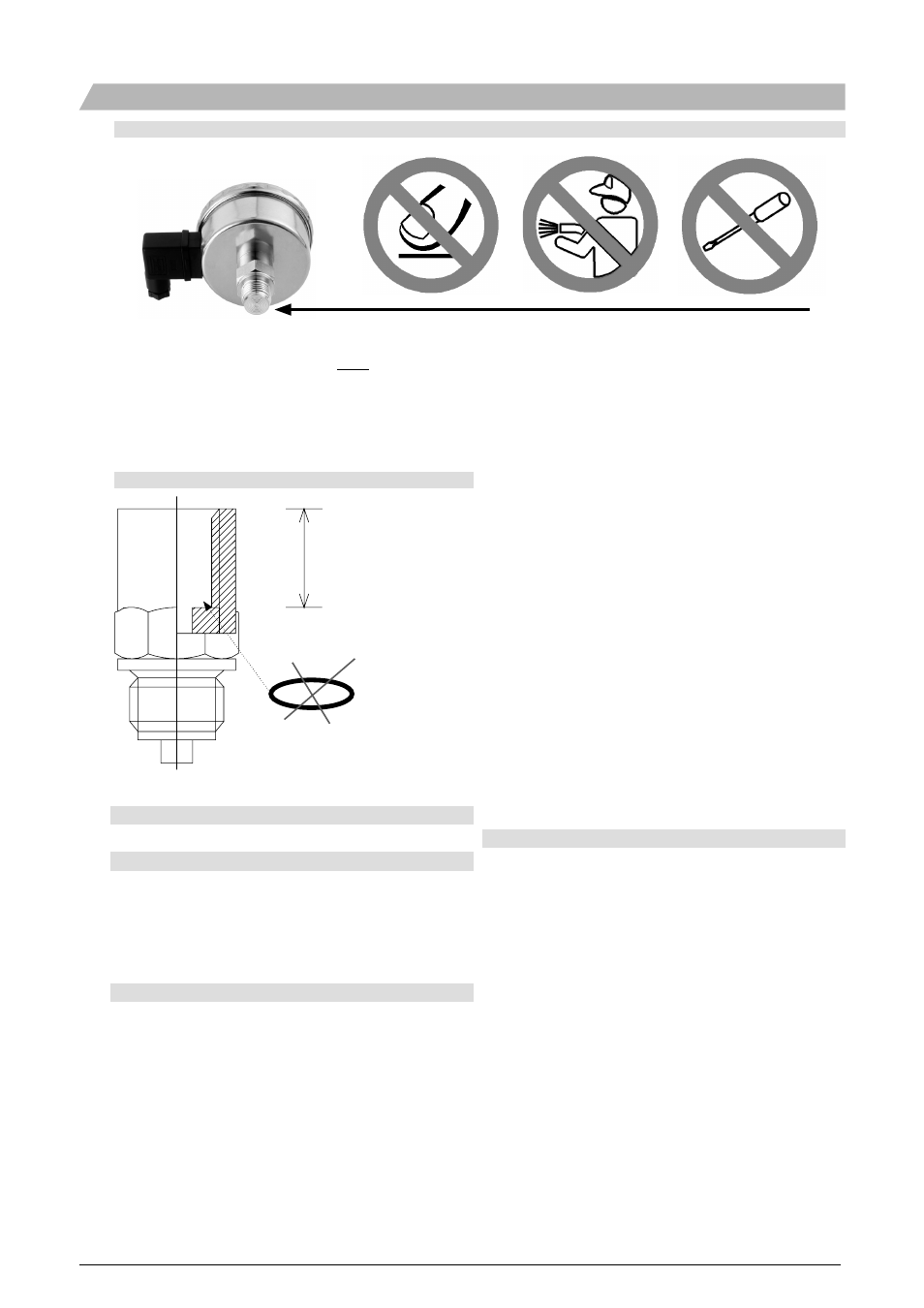

a) Remove protection-cap.

b) Install FlexBar 3431.

If a G1/2A version: Tighten up at 20 Nm.

c) Confi gure the display with a FlexProgrammer.

d) Establish a zero pressure condition (e.g. empty the tank)

d) Press and hold the Auto Zero button to reset the FlexBar.

Mechanical installation and cleaning

The pressure diaphragm must not be touched during installation.

Cleaning with pressurised cleaners and tools may damage the

diaphragm.

Refer to drawing no. 2:

If the transmitter has a 1/2” threaded neck, check before mounting

in a blind hole that the thread length is at least 22 mm. Use a gasket

ø28.6 x ø21.5 mm, made from a material proof against the measuring

medium, and do the clamping with an NV27 mm engineer’s wrench.

FlexBar 3431 can be mounted on a Baumer pressure gauge connec-

tion type no. 81 26-92X.

Installation

Factory guarantee is void on mechanical damages on the diaphragm.

Die Werksgarantie erstreckt sich nicht auf mechanische Schäden der Membran.

Les détériorations mécaniques de la membrane ne sont pas couvertes par la garantie .

Mekanisk skade på membranen er ikke omfattet af fabriksgarantien.

Mekaniska skador på trycktransmitterns membran omfattas inte av garantin.

Takuu ei koske käytön aikana tullutta mekaanista vauriota kalvossa.

>22 mm

2)

1)

For a FlexBar 3431 with a 3A/DN38 connection an O-ring with the

dimensions ø3.0 x ø19.0 mm must be used.

Mounting the pressure transmitter in closed systems (e.g. a stop cock)

can create overpressure in excess of that permit ted (400%), which

could deform the diaphragm and damage the pressure sensor.

The transmitter must not be exposed to pressure or surge exceeding 4

x span, max. 600 bar though.

The freezing point of process media and condensates must be

checked to prevent unintentional pressure rise when it is freezing.

Radiated heat may create excessively higher opera ting tempera tures

than the allowed -40...85°C (without display).

Adjusting the zero point

With FlexBar 3431 the electronic zero point can be adjusted from

-10...10% of the total measuring range.

The correct zero point pressure must be established prior to adjust-

ing the zero point. Tank and pressure transmitter must have the same

temperature. If the pressure transmitter has a relative measuring cell

from 0 bar, the zero point pressure is the same as the atmospheric

pressure or the level in a tank selected as zero point level. A pressure

transmitter measuring absolute pressure has a zero point lower than 1

mbar abs.

When the required zero point pressure has been established, the Zero

push button inside FlexBar must be pressed and held. The LED will

respond with one blink per second. When the actual zero pressure

level has been stored in the memory of the FlexBar the LED will blink

twice a second.

You can revert to the factory setting by reconfi guring the FlexBar 3431

in the PDM setup. The pressure transmitter can change its zero point

slightly, due to mechanical tension and the mounting direction selected

for the pressure diaphragm. Optimal results are therefore achieved

if the zero point is adjusted after the pressure transmitter has been

mounted in place.