Maintenance and lubrication, Maintenance, Row cleaner maintenance – Great Plains 207-216K Operator Manual User Manual

Page 23: Lubrication, Row cleaner hub, Maintenance and lubrication maintenance, Seasonal

2014-02-12

204-085M-A

Great Plains Manufacturing, Inc.

19

Maintenance and Lubrication

Maintenance

Proper servicing and adjustment is the key to long life for

any implement. With careful and systematic inspection,

costly maintenance, repairs and down time can be

avoided.

Crushing and High Pressure Fluid Hazard:

Before working on, servicing or making adjustments on

implement, raise it, install lift locks, and always disengage

power, shut off tractor engine, make sure all moving parts have

stopped, and all pressure in the system is relieved.

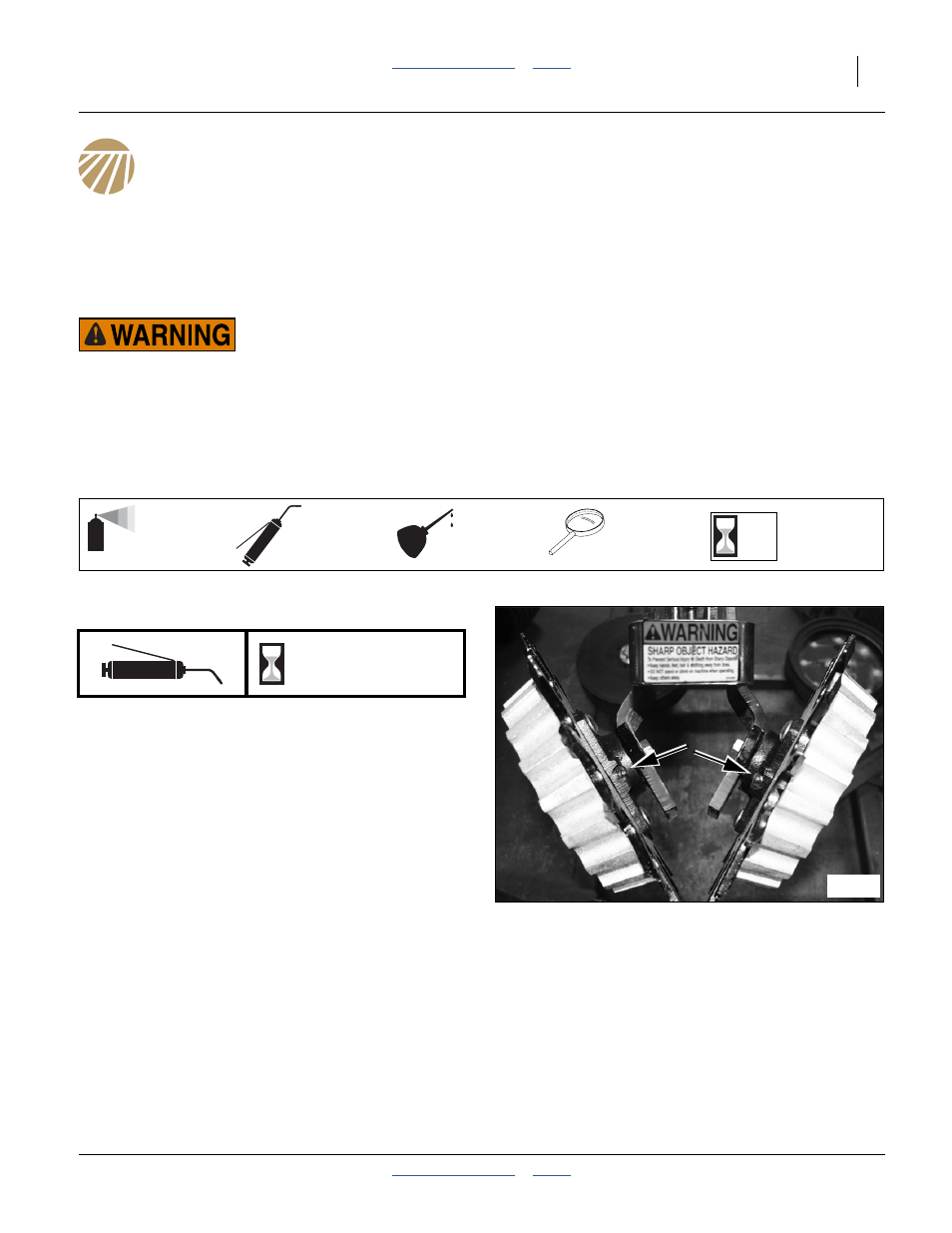

Row Cleaner Maintenance

1.

After several hours of operation, check row cleaners

for loose bolts, and loose or missing pins.

Check wheels for free rotation.

2.

At the end of the season, lubricate per the

instructions below.

Lubrication

Row Cleaner Hub

1 zerk each cleaner tine wheel; 1 or 2 per row

Type of Lubrication: Grease

Quantity: Until resistance is felt

Do not apply excessive pumping pressure. There is

some risk of damaging the seals.

Seasonal

50

Multi-purpose

spray lubricant

Multi-purpose

grease lubricant

Multi-purpose

oil lubricant

Intervals

(operating hours)

at which service

is required

Inspection

34208

27342