Opener-subframe adjustment – Great Plains CTA4000 HD Operator Manual User Manual

Page 49

Great Plains Manufacturing, Inc.

Adjustments

45

2012-11-28

160-037M

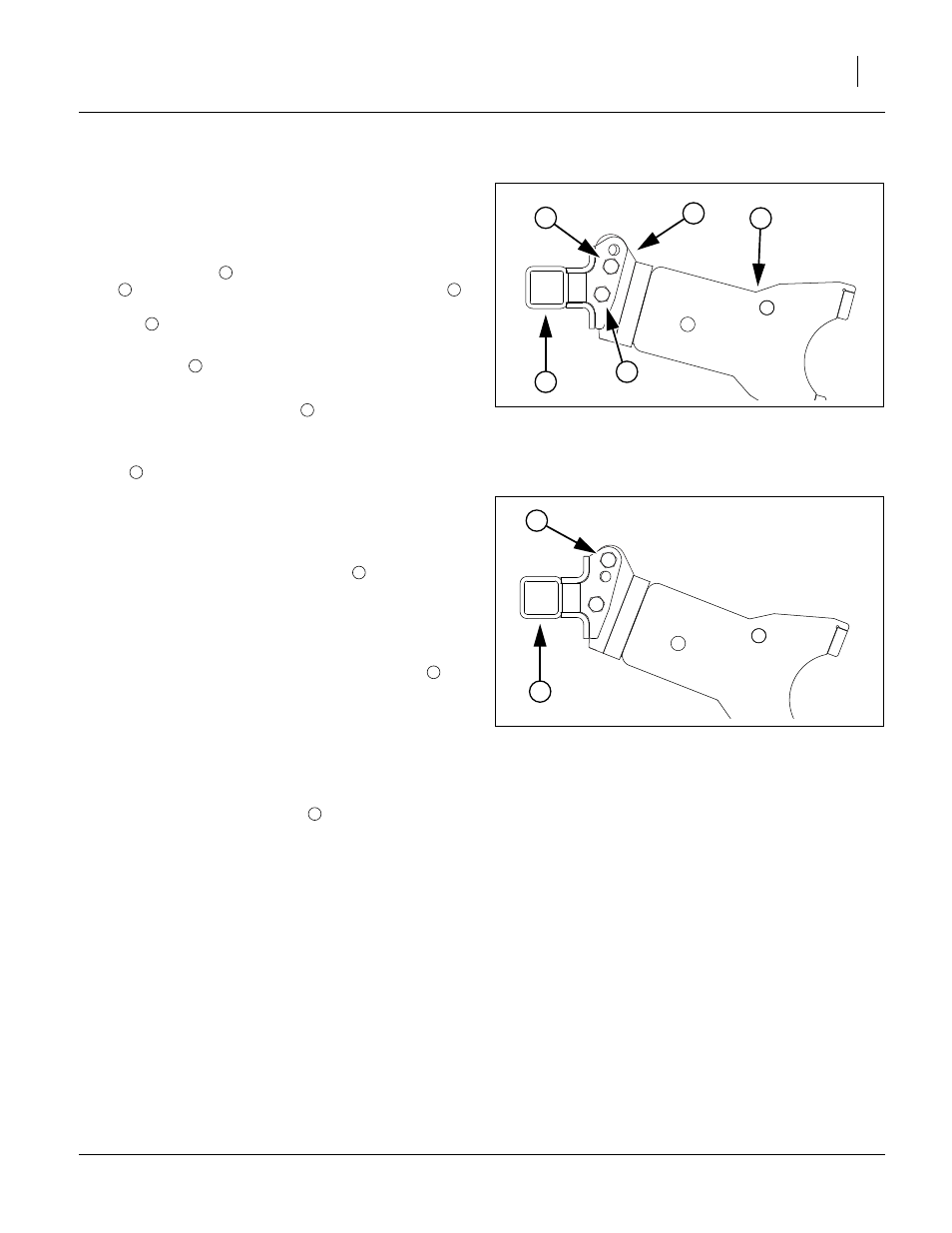

Opener-Subframe Adjustment

At higher down-pressures (above 1600 psi), the row

units can tend to tip forward. An adjust to the

mainframe/subframe pivot corrects this.

Refer to Figure 58 and Figure 59

The opener tool bar

is supported entirely by eight

arms

at the lift cylinders (not shown). The trunnion

at the arm end is connected to the tool bar by a lower

pivot bolt

which is never moved.

The arm-tool bar angle is controlled by an upper

adjustment bolt

, which occupies one of two positions.

• For low-to-1600 psi down pressures, the adjustment

bolt occupies the middle hole

of the frame mount

and trunnion.

• Above 1600, the adjustment bolt occupies the top

hole

of the frame mount and trunnion.

Set all arms the same.

To change the bolts (to high pressure):

1.

Have a jack at hand.

2.

Loosen the nuts on all the top bolts

.

3.

Lower the opener sub-frames.

4.

Leave the valve handles set to FIELD.

5.

Put the tractor hydraulic circuit in float.

6.

Place jack under an opener tool bar at an arm

.

7.

Lift the tool bar until the bolt is free.

8.

Remove the bolt.

9.

Repeat step 6 through step 8 the other arm of the

subframe.

10. Raise the jack until the top holes are aligned.

11. Insert the bolt in the top hole

and spin on a nut.

12. Repeat step 6 through step 11 for each sub-frame.

13. Tighten all nuts.

Changing from high to low is similar, except lower the

jack at step 7 and reverse the bolt movement.

Figure 58

Standard Down Force

(below 1600 psi)

26383

1

2

3

4

5

1

2

3

4

5

5

6

Figure 59

High Down Force

(above 1600 psi)

26384

1

6

5

1

6