Load sensing setup – Great Plains CTA4000 HD Operator Manual User Manual

Page 29

Great Plains Manufacturing, Inc.

Preparation and Setup

25

2012-11-28

160-037M

Load Sensing Setup

To operate the CTA4000HD, some tractors with

load-sensing or constant-flow hydraulics need a bypass

valve. See “Hydraulic Bypass Kit” on page 59 for

ordering information. Contact your Great Plains dealer to

order the valve.

Machine Damage Risk:

Failure to install the bypass valve may cause major tractor

damage. Contact your tractor dealer to verify if the bypass

valve is needed.

Refer to Figure 25

1.

After installing the bypass valve

, adjust as follows:

2.

Loosen lock-ring

and completely close off bypass

cross-flow by turning knob

fully clockwise.

Refer to Figure 26

3.

Set valve levers for Field operation.

4.

On tractor, adjust circuit flow-control valve so

openers raise and lower at a reasonable speed.

Note: The faster openers raise and lower, the greater

potential for oil heating, premature wear or tractor

damage.

5.

Engage tractor hydraulics for fan and

opener-lift-and-fold circuits. Lock hydraulic levers for

continuous oil flow. Make sure cart fan is operating at

normal speed (about 3600 rpm).

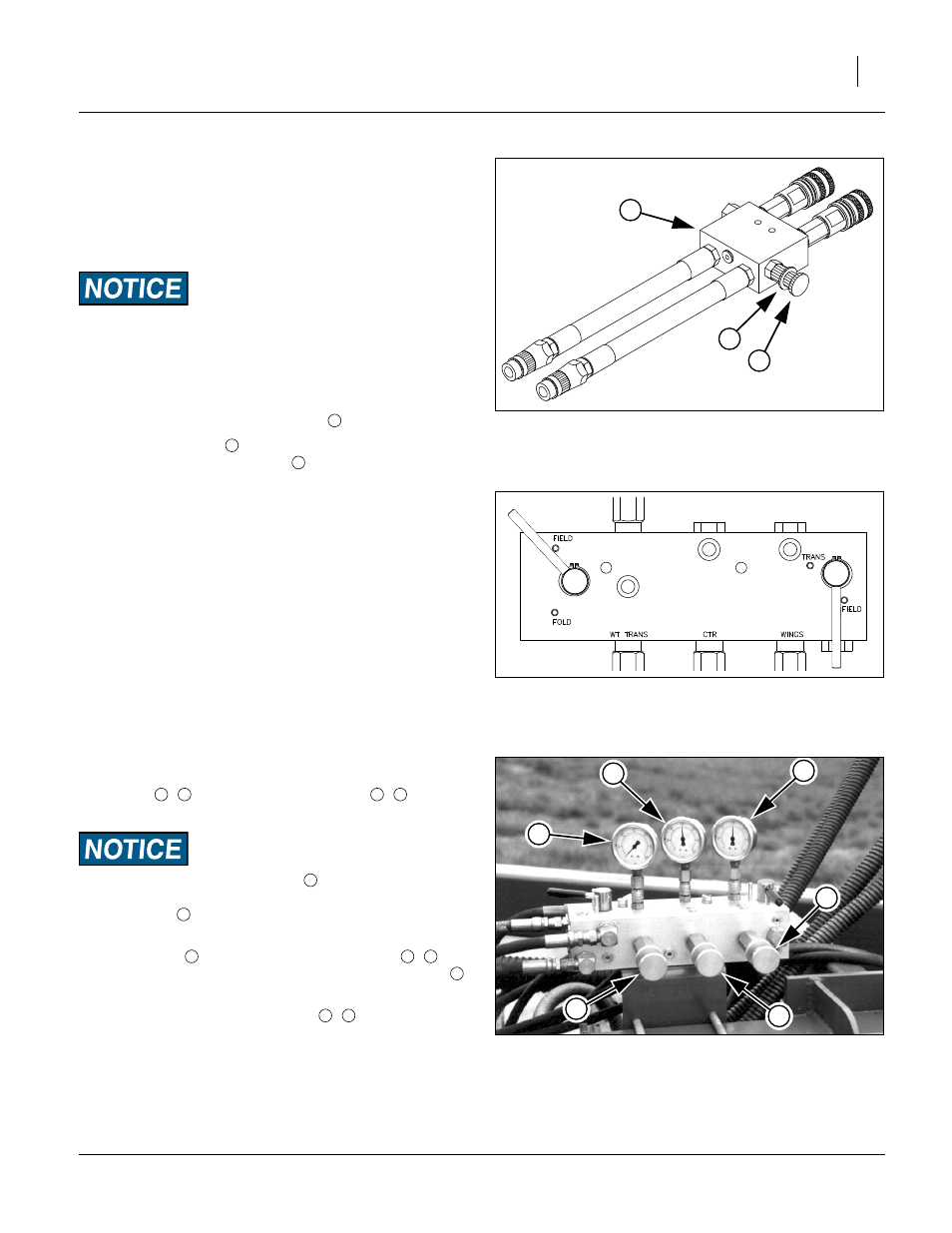

Refer to Figure 27 and Figure 25

6.

Adjust wing and center down-pressure-control

valves

,

on implement so gauges

,

read

1500 psi.

Do not adjust weight-transfer valve

at this time.

To avoid implement damage, never set weight-transfer valve

above 1000 psi

.

7.

While watching opener gauges, slowly adjust bypass

valve knob

just until needles on gauges

,

move down from 1500 psi. Lock bypass valve ring

at this setting.

8.

Adjust pressure-control valves

,

to desired

opener down pressure. See “Sub-Frame

Down-Force” on page 43.

Figure 25

Optional Bypass Valve

17987

3

2

1

1

2

3

Figure 26

Levers for Bypass Setup

26372

Figure 27

Pre-Adjusting for Bypass

26457

8

5

6

7

4

9

4

5

6

7

8

9

3

6

7

2

4

5