Great Plains PT8030 V1015 Operator Manual User Manual

Page 38

36

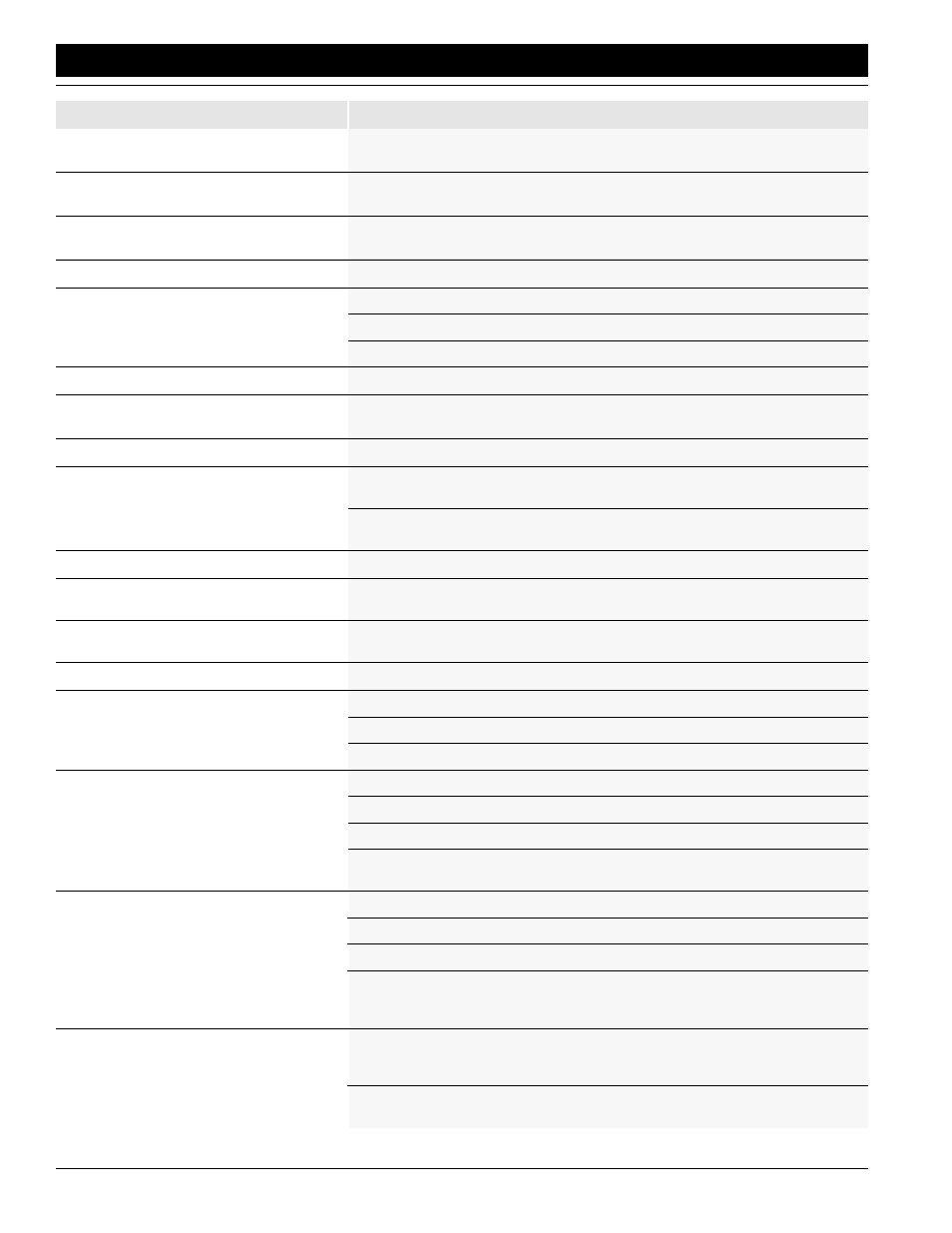

Section 4 Troubleshooting

PT6030 and PT8030 Pull-Type Planter 401-032M-B

4/12/05

Great Plains Mfg., Inc.

Closing wheels leave severe imprint in

soil.

Reduce down pressure on closing wheels. Refer to Row Unit Adjustments, “Adjust-

ments,” page 28.

Closing wheels not firming soil around

seed.

Increase down pressure on closing wheels. Refer to Row Unit Adjustments, “Adjust-

ments,” page 28.

Closing wheel running on top of seed

furrow.

Realign closing wheels. Refer to Row Unit Adjustments, “Adjustments,” page 28.

Repeated shearing of shaft cotter pin.

Drill shaft not aligned properly. Loosen bearing and align shaft.

Drive-wheel chain consistently falls off.

Chain may be too long. Remove offset link.

If chain links are stiff, oil or replace chain.

Check if trash is dislodging chain; if so, install trash guards.

No seed being planted.

Check that seed hopper is full of seed.

Opener disks and side gauge wheels

plugging.

Adjust gap between opener disks and side gauge wheels. Refer to Side Gauge

Wheels, “Adjustments,” page 29.

Planter will not lower.

Check that pressure and return hoses are fully engaged in SCV outlets.

Planter frame raises or lowers slowly.

Lower tractor hydraulic pressure. Tractor operating pressure must be a minimum

of 1500 psi.

Operator tractor with flow-control lever in the unrestricted position. Refer to your

tractor operator’s manual

Erratic or uneven lift.

Check for air in hydraulic system. Bleed system of air if necessary.

Planter will not raise.

Tractor hydraulic system bypassing oil. Readjust tractor’s hydraulic lever linkage.

Refer to your tractor operator’s manual.

Planter frame raises or lowers slowly.

Lower tractor hydraulic pressure. Tractor operating pressure must be a minimum

of 1500 psi.

No seed being planted.

Seed hopper empty. Fill seed hopper.

Markers not alternating.

Marker hoses not connected to marker valve correctly.

Check for air in marker valve. Bleed marker hydraulic system.

Marker valve defective. Replace valve. See your Great Plains dealer.

Marker floats off ground.

Air in hydraulic system. Bleed marker lift cylinder.

Alternator valve defective. Replace valve. Contact your Great Plains dealer.

Check for leaks in tractor hydraulic remote.

Marker cylinder not dropping down into J-slot. (Hose loop too short.) Lengthen

marker hydraulic hose loops.

Hydraulic marker functioning improperly

Check all hose fittings and connections for air and oil leaks.

Check tractor hydraulic oil level.

Check all bolts and fasteners.

If markers do not alternate:, check tractor flow controls and set to maximum oil

flow.If problem still exists, disassemble valve and check for contamination or spool

damage.

Blade does not mark

The maximum marker down float is limited by the slot in the pivot link. If the blade

does not drop down to follow depressions in the field, make sure the marker cylin-

der is fully extended.

The blade may be reversed to pull dirt in or throw dirt out depending on soil condi-

tions.

Problem

Possible Cause and Solution