Warning, Marker adjustments – Great Plains PT8030 V1015 Operator Manual User Manual

Page 33

31

Section 3 Adjustments

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

Great Plains Mfg., Inc.

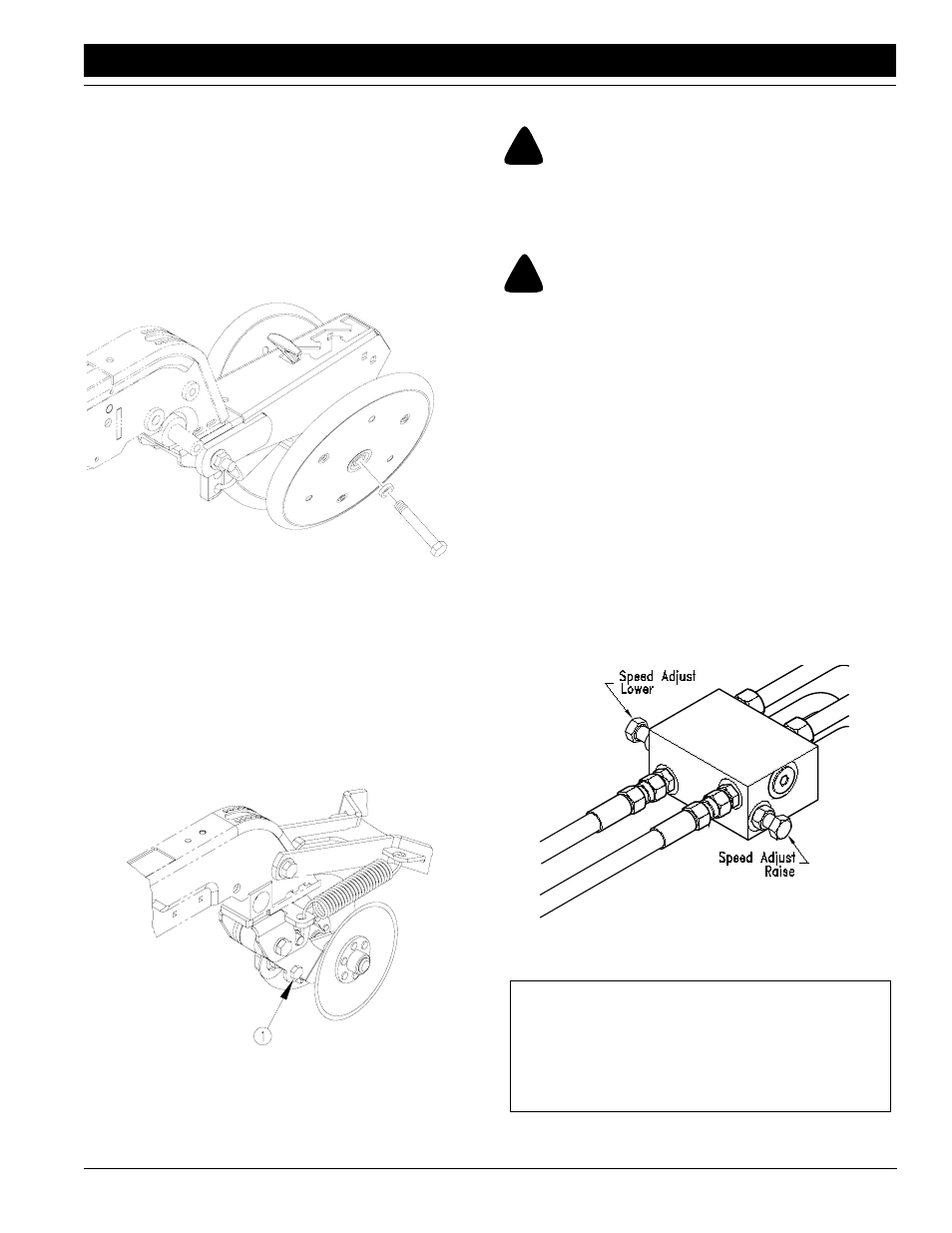

Offset. The closing wheels can be offset to help prevent

trash from plugging the closing wheels.

To offset the closing wheels:

1.

Raise planter slightly to remove weight from closing

wheels.

2.

Remove 5/8-inch bolt attaching wheel to press-wheel

arm. See Figure 3-18.

3.

Move closing wheel to rear mounting hole and reattach

with 5/8-inch bolt. Torque bolt as recommended on

Torque Values Chart, “Appendix,” page 55.

17893

Figure 3-18

Closing Wheel Offset

If the closing wheels are not offset, mount wheels in the

front holes of press-wheel arm.

Closing Disk Option

For proper seed-to-soil contact, the closing disks must

have enough down pressure to close the seed trench with-

out unnecessary soil compaction.

To adjust down pressure on closing disks, ratchet spring

cam to next cam height by turning head of support bolt (1)

clockwise. Refer to Figure 3-19.

17890

Figure 3-19

Closing Disk and Tube Holes

Marker Adjustments

!

WARNING!

Pinching and crushing hazard. The moving markers could

pinch or crush bystanders. Never allow anyone near the planter

when cycling the markers. Reduce marker folding speed to a

safe speed.

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with this type

of injury. Foreign fluids in the tissue must be surgically removed

within a few hours or gangrene will result.

Folding Speed

The marker hydraulic system is equipped with needle

valves to control how fast each marker operates. The nee-

dle valves are built into the sequence valve body. There

are two hex adjustment heads, one for controlling marker

speed up and one for controlling marker speed down.

Excessive folding speeds can cause marker damage.

With the tractor engine at an operating rpm, loosen jam

nut and adjust the needle valve to limit the marker to a safe

operating speed. Make sure all adjustments are made

with warm oil. Fold the marker up and down a few times

and recheck for pinching and kinking of hoses.

15029

Figure 3-20

Flow Control Raise/Lower

IMPORTANT: JIC fittings do not require high torque.

JIC and O-ring fittings do not require sealant. Always

use liquid pipe sealant when adding or replacing

pipe-thread fittings. To avoid possible danger of

cracking hydraulic fittings from over tightening, do not

use plastic sealant tape.