Owner assistance, Description of unit, Using this manual – Great Plains PT8030 V1015 Operator Manual User Manual

Page 12: Introduction, Product support

10

Introduction

PT6030 and PT8030 Pull-Type Planter 401-032M-B

4/12/05

Great Plains Mfg., Inc.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

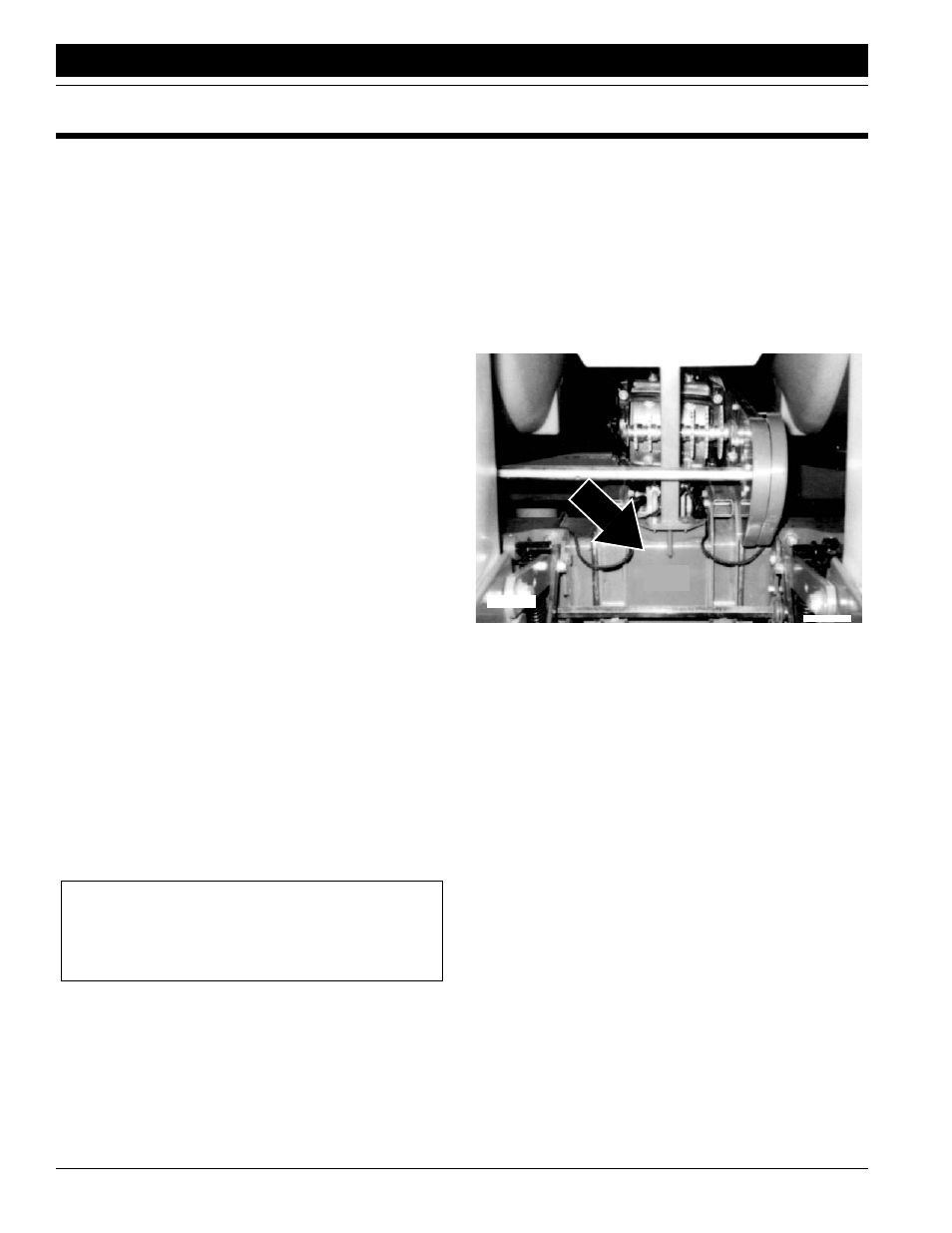

Great Plains dealer. The serial-number plate is located on

the 7-by-7-inch, main frame tube on the left-hand side of

the planter as shown in Figure A.

Great Plains

MANUFACTURING INCORPORATED

ASSARIA, KANSAS 67416

MODEL NO.

PT 6030

SERIAL NO.

GP-U0000000

14921

Figure A

Serial Number

Record your planter model and serial number here for quick

reference:

Model Number: _________________________________

Serial Number: _________________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1.

Discuss the matter with your dealership service man-

ager. Make sure they are aware of any problems so

they can assist you.

2.

If you are still not satisfied, seek out the owner or gen-

eral manager of the dealership.

3.

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

Introduction

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper setup, maintenance and safe operating practices

will help you get years of satisfactory use from the ma-

chine.

Description of Unit

The 6- and 8-row, pull-type planter is a towed planting im-

plement. The frame consists of 7-by-7-inch tubing. Plant-

ing rates are adjustable by changing sprockets on the

planter transmission or contact drive. Row units are

mounted on the frame. Seed hoppers are standard on the

row units; chemical hoppers and granular-chemical appli-

cators are available. Springs on each row unit provide

down pressure needed for the double-disk openers to

make a seed trench. Finger-pickup meters singulate and

dispense seed from the hopper and deliver it to the trench.

Seeding depth is controlled by side gauge wheels on the

openers. Closing wheels or disks close the trench. With an

optional 5-by-7-inch fertilizer bar, the planter can be outfit-

ted with dry or liquid fertilizer application and tillage attach-

ments.

Intended Usage

Use this implement for planting row crops in large fields.

Tow the implement behind an agricultural tractor at speeds

of less than 20 mph. The unit is designed for convention-

ally tilled fields but can be used in no- or minimum-till con-

ditions if outfitted with optional tillage attachments.

Using This Manual

This manual will familiarize you with safety, assembly, op-

eration, adjustments, troubleshooting and maintenance.

Read this manual and follow the recommendations to help

ensure safe and efficient operation.

The information in this manual is current at printing. Some

parts may change to assure top performance.

Definitions

Right-hand and left-hand as used in this manual are deter-

mined by facing the direction the machine will travel while

in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct operation,

read and follow the directions provided before continu-

ing.

NOTE: Useful information related to the preceding topic.