Prestart checklist, Field operation – Great Plains PT8030 V1015 Operator Manual User Manual

Page 16

14

Section 2 Operating Instructions

PT6030 and PT8030 Pull-Type Planter 401-032M-B

4/12/05

Great Plains Mfg., Inc.

Section 2

Operating Instructions

This section covers general operating procedures. Experi-

ence, machine familiarity and the following information will

lead to efficient operation and good working habits. Al-

ways operate farm machinery with safety in mind.

Prestart Checklist

1.

Carefully read “Important Safety Information,” be-

ginning on page 1.

2.

Clean any dirt or grease off chains and other moving

parts. Check chains for proper tension and alignment

as shown in Chain Tension, “Maintenance and Lubri-

cation,” page 39.

3.

Check that planter tires are the correct size and prop-

erly inflated as indicated on Tire Inflation Chart, “Ap-

pendix,” page 56.

4.

Check all bolts, pins and fasteners. Torque as speci-

fied on Torque Values Chart, “Appendix,” page 55.

5.

Lubricate planter as indicated under Lubrication,

“Maintenance and Lubrication,” page 44.

6.

Check planter for worn or damaged parts. Repair or

replace before going to the field.

7.

Check that hoppers are free of dirt and debris. Turn

meter-drive shaft by hand to be sure drive shaft and

seed meter turn freely.

Field Operation

1.

Perform all checks listed on Prestart Checklist, this

page.

2.

Hitch planter to a tractor with sufficient horsepower.

Refer to Tractor Requirements, “Specifications and

Capacities,” page 53, and Hitching Planter to Tractor,

“Preparation and Setup,” page 11.

3.

Set and calibrate planting rate as explained under

Planting Rate, “Adjustments,” page 17.

4.

Load seed hoppers with clean seed. Add 1 teaspoon

of graphite to each seed hopper. Replace hopper lids.

5.

Adjust down pressure on row units to match field con-

ditions. Set row units to desired planting depth. Refer

to Row Unit Adjustments, “Adjustments,” page 28.

6.

Check if planter is level. Refer to Leveling Planter,

“Preparation and Setup,” page 12.

7.

Lower planter, pull forward and begin planting.

8.

Always raise planter for field turns. Meters will stop

automatically as you raise planters.

Meter Clutches

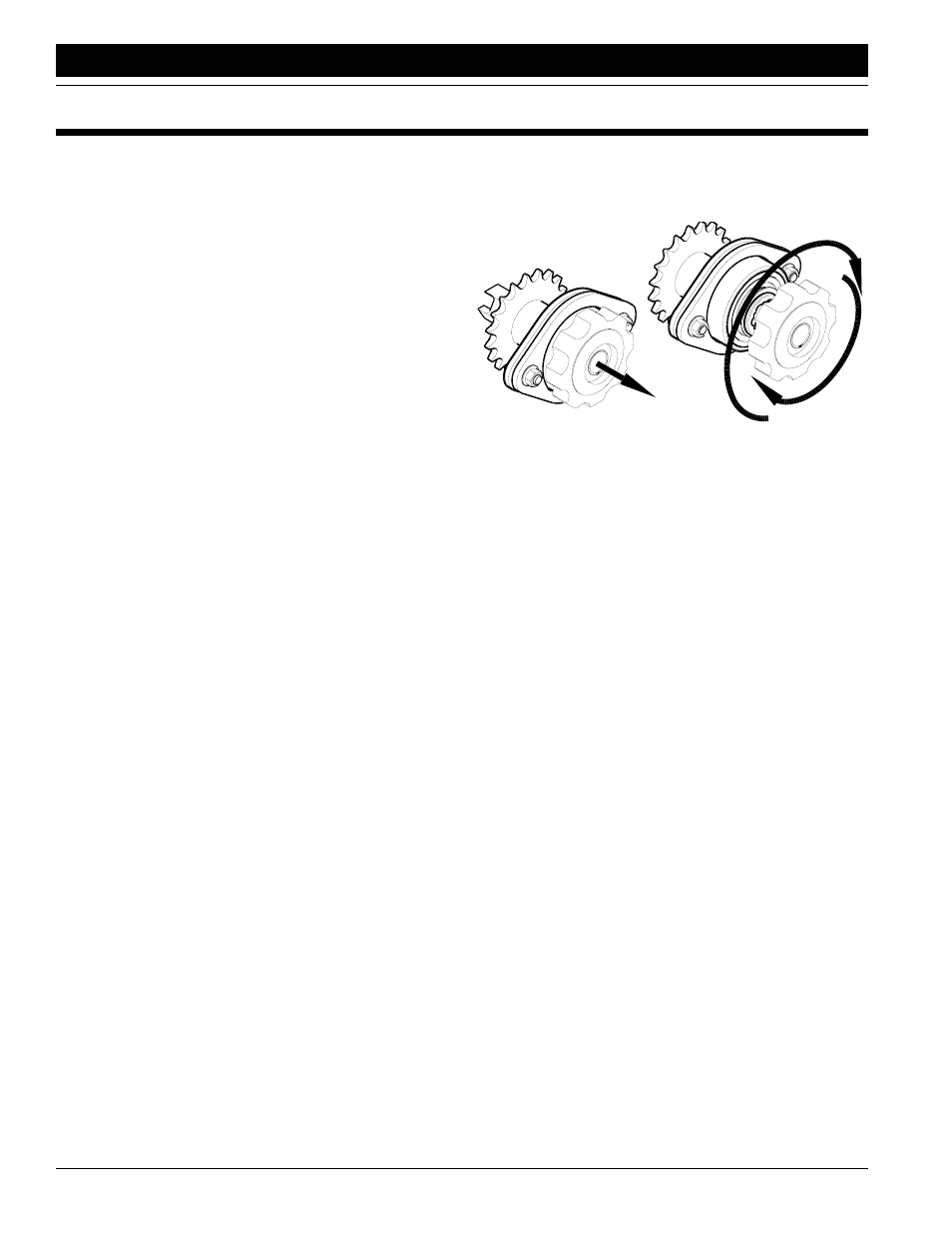

To disengage seed- and chemical-hopper clutches, pull

and rotate knobs until meters are disengaged. See Figure

2-1.

17887

Figure 2-1

Meter Clutch

To engage clutches, pull and rotate knobs until meters

reengage.

Row Unit Operation

Never back up with row units in ground. If you do, check all

openers to be sure none are clogged. Always lift planter

out of ground when turning at row ends and for other

short-radius turns.

For information on planting-depth and down-pressure

adjustments, refer to Row Unit Adjustments, “Adjust-

ments,” beginning on page 28.

Chemical Hoppers

The optional chemical hopper comes in two versions: one

chemical meter or two chemical meters with a divider that

separates the hopper into two compartments.

Before filling chemical hoppers, clean any foreign objects

out of hoppers. To remove hopper from row unit, disen-

gage meter clutch and undo over-center latch at front of

hopper. See Figure 2-2.

Set and calibrate chemical-application rate as explained

under Granular Chemical Rates, “Adjustments,” page 21.

Fill chemical hoppers and replace hopper lids before op-

erating planter.

Periodically clean dirt and foreign objects out of chemical

hoppers.