Frame height, Single gauge wheel, Dual gauge wheels – Great Plains 2025P Operator Manual User Manual

Page 39

8/14/2006

118-928M

37

Adjustments

Frame Height

Drill operating height directly affects the working

range of the drill openers. Initially adjust frame

height as explained under “Leveling Drill”, page 17.

You can make further adjustments to compensate

for field conditions.

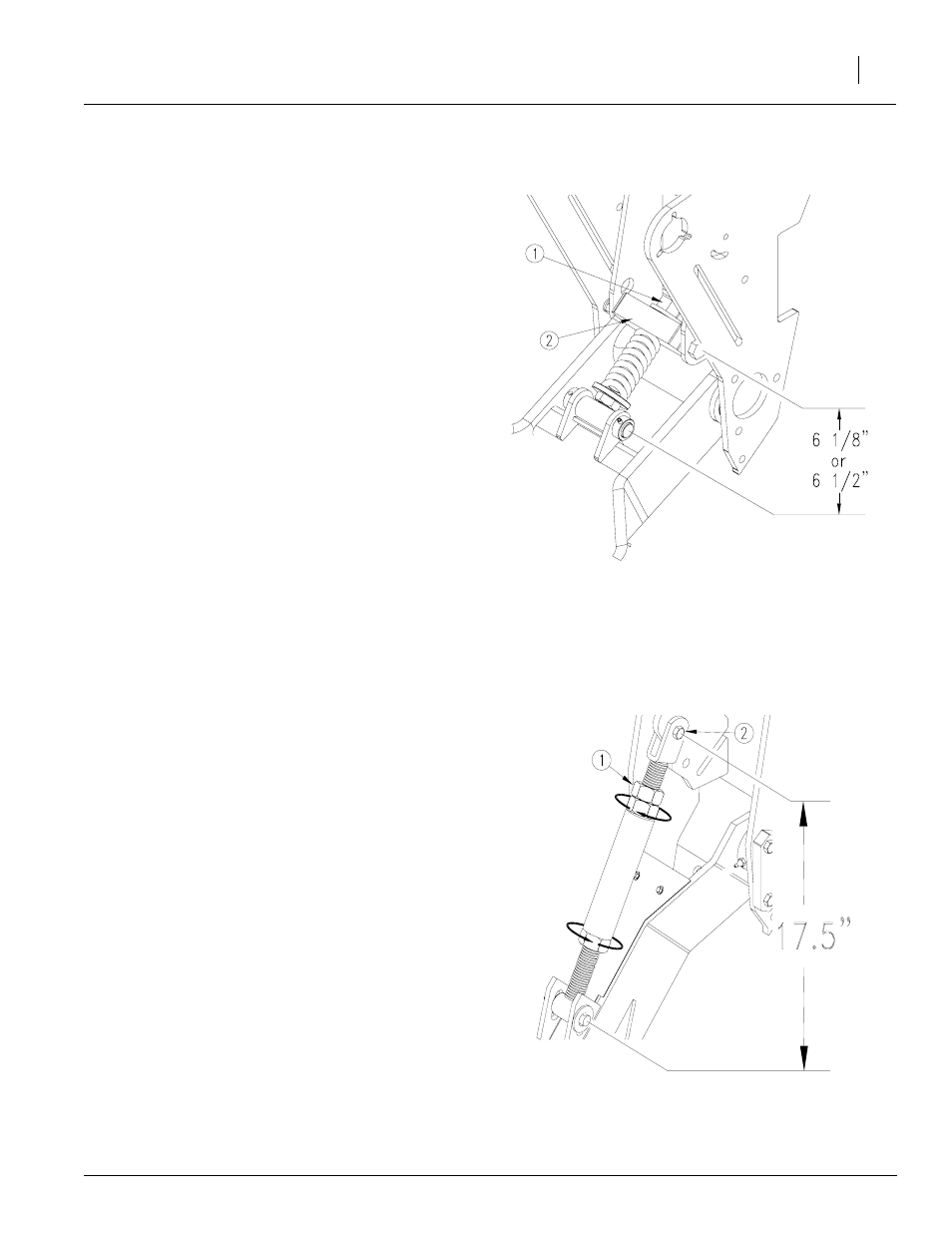

Single Gauge Wheel

Refer to Figure 45

1.

Make sure block mount of the spring linkage (2)

is in the lower mount hole for planting in bedded

irrigation. The upper hole is for non-bedded

ground.

2.

Set spring linkage length. Turn spring linkage to

shorten or lengthen as necessary. Initially set

length to 6 1/2 inches between pin centers to

achieve a 26-inch frame height for 25 series

openers and 6 1/8 inches to achieve a 24-inch

frame height for 20 series openers. When ad-

justing the linkage length, remember:

• Lengthening linkage raises drill.

• Shortening linkage lowers drill.

Level drill with top three-point link.

NOTE: Lowering the drill increases the risk of

opener damage on rocks or obstructions.

Dual Gauge Wheels

Refer to Figure 46

1.

Loosen jam nut near top clevis of each gauge-

wheel turnbuckle.

NOTE: Jam nut is left-hand threaded.

2.

Make sure upper clevis (2) is in upper mount

hole as shown for 20 series and in the lower

mount hole for HD 10 series.

3.

Set turnbuckle length. Turn turnbuckle to short-

en or lengthen as necessary. Initially set length

to 17 1/2 inches between pin centers to achieve

a 24-inch dimension for 20 series openers and

26-inch dimension for HD 10 series openers.

When adjusting the turnbuckle length, remem-

ber:

• Lengthening turnbuckle raises drill.

• Shortening turnbuckle lowers drill.

4.

After adjusting both turnbuckles to the same

length, tighten jam nuts.

5.

Level drill with top three-point link.

NOTE: Lowering the drill increases the risk of

opener damage on rocks or obstructions.

Figure 45

Single Gauge Wheel Linkage

Figure 46

Dual Gauge Wheel Turnbuckle

22845

22848