Carrier MOTORMASTER 48/50P5030-100 User Manual

Page 11

11

Step 3 — Configure Motormaster

®

V Con-

trol —

The Motormaster V control is configured for propor-

tional integral (PI) control mode. The Motormaster V varies

the condenser fan motor speedto maintain a set point of

320 psig liquid line pressure in response to a 0 to 5 vdc feed-

back signal from the liquid line pressure transducer. No addi-

tional programming is required. See Table 4. Note that the

pressure transducer must be attached for proper configuration.

Table 4 — Configuration Table

The following ComfortLink control configurations must be

set when using a Motormaster V device:

• Configuration

COOL

M.M. = YES

• Configuration

COOL

LLAG = CIRCUIT A (size

030-060 units only)

Step 4 — Test Motormaster V Control —

To test the

control and motor in the test mode, run compressor no. 1. The

Motormaster V electronic control adjusts the fan speed based

on the liquid line pressure input. Ensure that fans are rotating

clockwise (as viewed from above). If rotation is backward,

lock out all power then swap 2 leads AFTER the Motormaster

V control.

START-UP

The Motormaster V electronic control will be powered up

as long as unit voltage is present. When the system calls for

cooling, the fan relay will be energized to initiate the start-up

sequence for the Motormaster V electronic control. The LED

(light-emitting diode) will display the speed of the motor. The

display range will be 8 to 60 Hz. The Motormaster V electronic

control will start the condenser fan when the compressor en-

gages. The control will adjust the fan speed to maintain ap-

proximately 320 psig. Above that pressure, the fan should op-

erate at full speed.

For size 030-060 units, the Motormaster V control uses a 0

to 5 vdc signal input from a pressure transducer attached to the

liquid line service valve gage port on circuit A.

For size 070-100 units, two Motormaster V devices are

used, one for each circuit. The circuit A Motormaster V control

uses a 0 to 5 vdc signal input from a pressure transducer at-

tached to the liquid line service valve gage port on circuit A.

The circuit B Motormaster V control uses a 0 to 5 vdc signal

input from a pressure transducer attached to the liquid line ser-

vice valve gage port on circuit B.

The pressure transducer(s) are connected to terminals 2, 5

and 6 on the controller. The controller is configured by jumper

wires and sensor input types. No field programming is re-

quired. If controller does not function properly, the information

provided below can be used to program and troubleshoot the

drive.

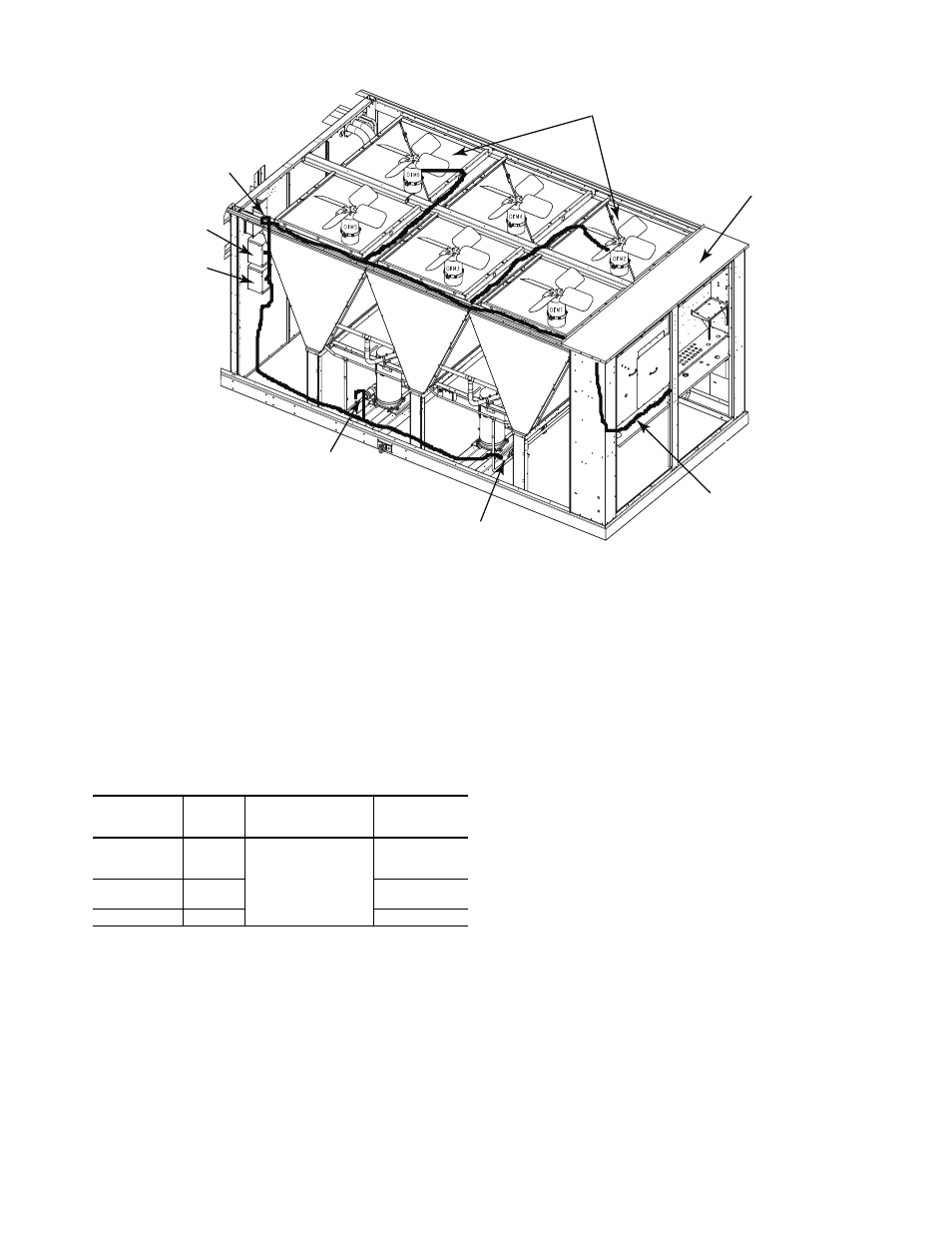

REMOVE TWO FAN DECKS TO

GAIN ACCESS TO ROUTE WIRING TO

OFM 2 AND OFM 6

ROUTE THROUGH

SNAP BUSHING

MOTORMASTER A

CONTROL

MOTORMASTER B

CONTROL

TRANSDUCER A

TRANSDUCER B

RUN ELECTRICAL HARNESSES

UP THE SIDE OF THE UNIT

IN THE SPACE BETWEEN THE

CORNER POST AND THE

CONTROL BOX. ROUTE WIRES

INTO WIRE TRAY AND RUN

TO MMV A/B AND OFM 6/2

REMOVE PANEL

Fig. 10 — MMV Control Mounting — 48/50P090,100 Units

a48-8568

NOMINAL

VOLTAGE

(V-Ph-Hz)

MODE

CONTROL INPUT

(Pin 5)

START

CONTACTS

230-3-60

460-3-60

575-3-60

1

Internal PI control,

0-5V feedback

TB 1,2

208-3-60

380-3-60

2

TB 13A,2

400-3-50

4

TB 13C,2