Carrier 48TC*D08 User Manual

Page 83

83

The PremierLinkt controller will generate a Linkage

Communication Failure alarm if a failure occurs for 5

consecutive minutes once a Linkage has previously been

established. It will then revert back to its own SPT,

setpoints and occupancy schedule for control. For this

reason, Carrier strongly recommends that an SPT be

installed in the space on open plenum systems or in the

return air duct of ducted return air systems to provide

continued

backup

operation.

When

Linkage

communication is restored, the controller will generate a

return to normal.

For more information on how the PremierLink controller

is used in conjunction with the Carrier 3V control system,

contact your CCN controls representative.

IMPORTANT: The PremierLink controller should not be

used as a linked air source in a ComfortIDt VAV system.

The ComfortID VAV system will NOT function correctly

when applied with a PremierLink controller as the air

source, resulting in poor comfort control and possible

equipment malfunction.

NOTE: The PremierLink controller can be used as an air

source in a 3V Pressure Independent (PI) System (a 3V

Linkage

Coordinator

with

ComfortID

PI

Zone

Controllers), but it should not be used as an air source

with ComfortID controllers unless a 3V zone controller is

used as the Linkage Coordinator. Contact your Carrier

CCN controls representative for assistance.

Demand Limit — If the demand limit option is enabled,

the control will receive and accept Redline Alert and

Loadshed commands from the CCN loadshed controller.

When a redline alert is received, the control will set the

maximum stage of capacity equal to the stage of capacity

that the unit is operating at when the redline alert was

initiated.

When loadshed command is received the control will

reduce capacity as shown in Table 32.

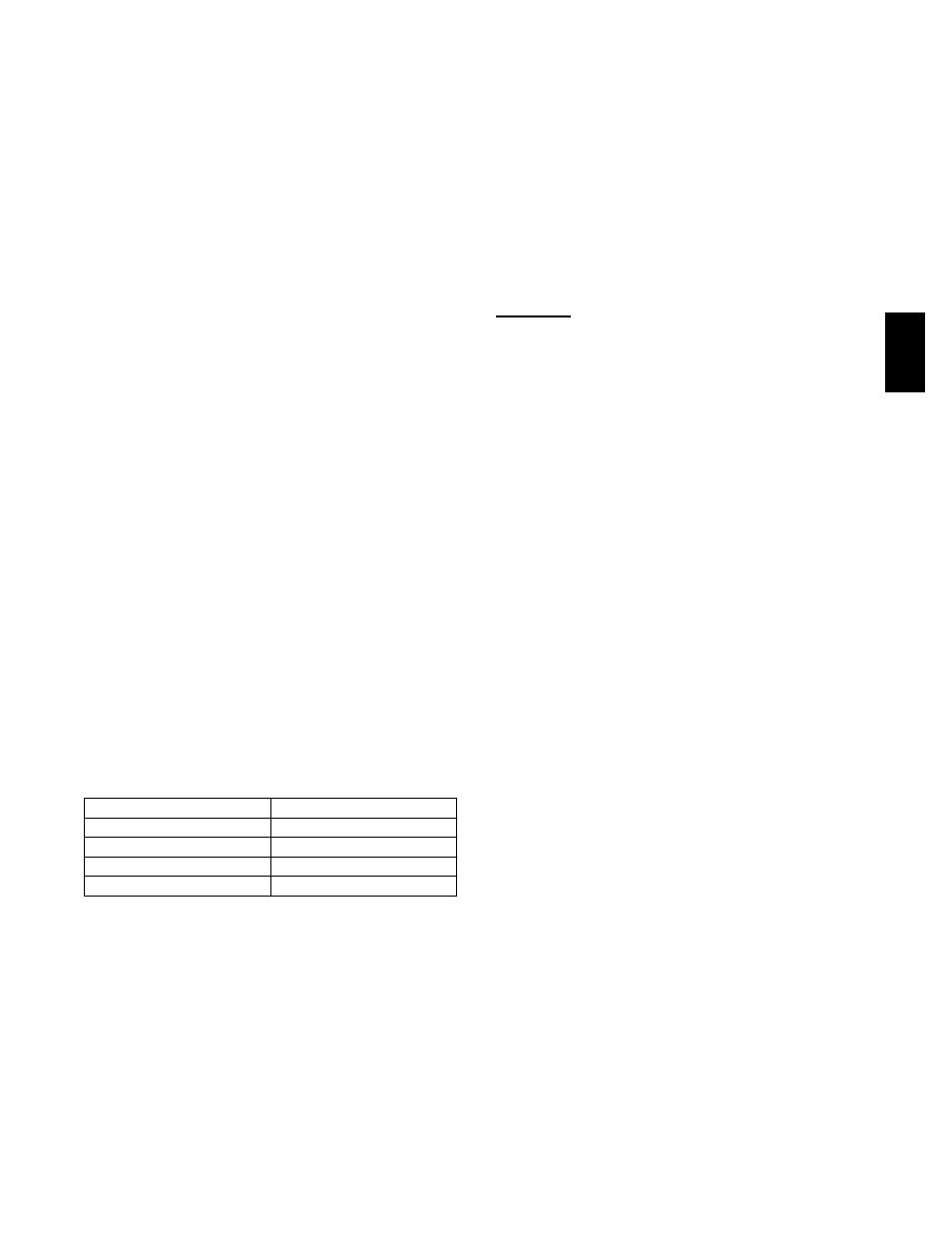

Table 32 – Loadshed Command — Gas and Electric

Heat Units

CURRENT CAPACITY

NEW CAPACITY

CMP1

DX Cooling OFF

CMP1+CMP2

CMP1

HS1

Heat OFF

HS1+HS2 (+HS3)

HS1

The controller will have a maximum demand limit timer

of 1 hour that prevents the unit from staying in load shed

or redline alert longer than 1 hour in the event the

controller loses communication with the network load

shed module. Should the maximum demand limit timer

expire prior to receiving the loadshed device command

from CCN, the control will stop demand limit mode and

return to normal operation.

RTU--MP Sequence of Operation

The RTU--MP will control the compressor, economizer

and heating outputs based on its own space temperature

input and setpoints. An optional CO

2

IAQ sensor mounted

in the space can influence the economizer minimum

position. The RTU--MP has its own hardware clock that is

set automatically when the software is installed on the

board. The RTU--MP’s default is to control to occupied

setpoints all the time, until a type of occupancy control is

set. Occupancy types are described in the scheduling

section. The following sections describe the operation for

the functions of the RTU--MP. All point objects that are

referred to in this sequence will be in reference to the

objects as viewed in BACview

6

Handheld.

Scheduling

Scheduling is used to start heating or cooling (become

occupied) based upon a day of week and a time period and

control to the occupied heating or cooling setpoints.

Scheduling functions are located under occupancy

determination and the schedule menu accessed by the

Menu softkey (see Appendix -- for menu structure). Your

local time and date should be set for these functions to

operate properly. Five scheduling functions are available

by changing the Occupancy Source to one of the

following selections:

Always Occupied (Default Occupancy)

The unit will run continuously. RTU--MP ships from the

factory with this setting.

Local Schedule

The unit will operate according to the schedule configured

and stored in the unit. The local schedule is made up of

three hierarchy levels that consist of two Override

schedules, twelve Holiday and four Daily schedules, and

are only accessible by the BACview screen (handheld or

virtual).

The Daily schedule is the lowest schedule in the hierarchy

and is overridden by both the Holiday and Override

schedule. It consists of a start time, a stop time (both in 24

hour mode) and the seven days of the week, starting with

Monday and ending in Sunday. To select a daily schedule

scroll to the Schedules menu off of the Menu selection.

Enter the User password and change the Occupancy

Source to Local Schedule. Scroll down and over to the

Daily menu and press enter. Choose one of the four Daily

schedules by pressing the Next softkey and change the

Use? point from NO to YES by selecting the point and

pressing the INCR or DECR softkey. Press the OK softkey

and scroll to the start and stop times. Edit these times

following the same steps as the Use? point. Finally scroll

down to the Days: section and highlight the days required

for the Daily schedule by INCR or DECR softkeys and

press OK softkey.

48TC