Rtu--mp control system – Carrier 48TC*D08 User Manual

Page 44

44

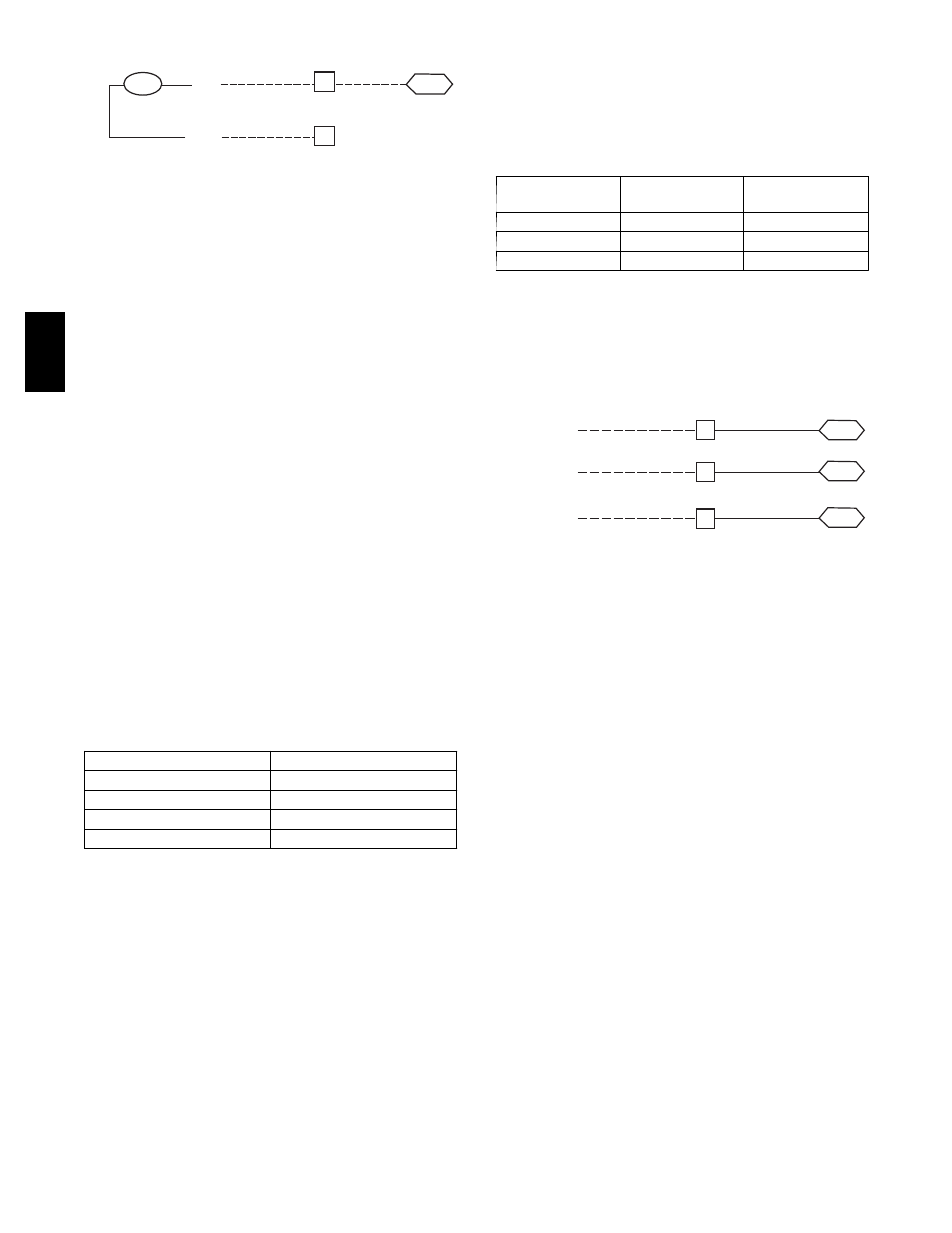

Power Exhaust

J8-3

15

C

TB1

THERMOSTAT

PL

PEC

TAN

GRA

LCTB

C08120

Fig. 58 -- PremierLinkt Power Exhaust Output

Connection

Space Relative Humidity Sensor — The RH sensor is not

used with 48TC models at this time.

CCN Communication Bus — The PremierLink controller

connects to the bus in a daisy chain arrangement.

Negative pins on each component must be connected to

respective negative pins, and likewise, positive pins on

each component must be connected to respective positive

pins. The controller signal pins must be wired to the signal

ground pins. Wiring connections for CCN must be made

at the 3--pin plug.

At any baud (9600, 19200, 38400 baud), the number of

controllers is limited to 239 devices maximum. Bus length

may not exceed 4000 ft (1219m), with no more than 60

total devices on any 1000--ft (305m) section. Optically

isolated RS--485 repeaters are required every 1000 ft

(305m).

NOTE: Carrier device default is 9600 baud.

COMMUNICATION BUS WIRE SPECIFICATIONS —

The CCN Communication Bus wiring is field--supplied

and field--installed. It consists of shielded 3--conductor

cable with drain (ground) wire. The cable selected must

be identical to the CCN Communication Bus wire used for

the entire network.

See Table 19 for recommended cable.

Table 19 – Recommended Cables

MANUFACTURER

CABLE PART NO.

Alpha

2413 or 5463

American

A22503

Belden

8772

Columbia

02525

NOTE: Conductors and drain wire must be at least 20

AWG, stranded, and tinned copper. Individual conductors

must be insulated with PVC, PVC/nylon, vinyl, Teflon, or

polyethylene. An aluminum/polyester 100% foil shield

and an outer jacket of PVC, PVC/nylon, chrome vinyl, or

Teflon with a minimum operating temperature range of

--20 C to 60 C is required. Do not run communication wire

in the same conduit as or next to any AC voltage wiring.

The communication bus shields must be tied together at

each system element. If the communication bus is entirely

within one building, the resulting continuous shield must

be connected to ground at only one single point. If the

communication bus cable exits from one building and

enters another building, the shields must be connected to

the grounds at a lightning suppressor in each building (one

point only).

Connecting CCN bus:

NOTE: When connecting the communication bus cable,

a color code system for the entire network is

recommended to simplify installation and checkout. See

Table 20 for the recommended color code.

Table 20 – Color Code Recommendations

SIGNAL TYPE

CCN BUS WIRE

COLOR

CCN PLUG PIN

NUMBER

+

Red

1

Ground

White

2

---

Black

3

Connect the CCN (+) lead (typically RED) to the unit’s

TB1--12 terminal. Connect the CCN (ground) lead

(typically WHT) to the unit’s TB1--14 terminal. Connect

the CCN (--) lead (typically BLK) to the unit’s TB1--16

terminal. See Fig. 59.

CCN Bus

J2-1

J2-2

GND (WHT)

12

14

TB1

J2-3

– (BLK)

16

TB1

TB1

PL

+ (RED)

C08276

Fig. 59 -- PremierLink CCN Bus Connections

RTU--MP CONTROL SYSTEM

The RTU--MP controller, see Fig. 60, provides expanded

stand--alone operation of the HVAC system plus

connection and control through communication with

several Building Automation Systems (BAS) through

popular third--party network systems. The available

network systems are BACnet MP/TP, Modbus and

Johnson J2. Communication with LonWorks is also

possible by adding an accessory interface card to the

RTU--MP. Selection of the communication protocol and

baud rate are made at on--board DIP switches.

Carrier’s diagnostic display tools BACviewer6 Handheld

and Virtual BACview (loaded on a portable PC) must be

used with the RTU--MP controller. Connection to the

RTU--MP board is at the J12 access port, see Fig. 60.

The RTU--MP control is factory--mounted in the 48TC

unit’s main control box, to the left of the LCTB. See Fig.

61. Factory wiring is completed through harnesses

connected to the LCTB. Field connections for RTU--MP

sensors will be made at the Phoenix connectors on the

RTU--MP board. The factory--installed RTU--MP control

includes the supply--air temperature (SAT) sensor. The

outdoor air temperature (OAT) sensor is included in the

FIOP/accessory EconoMi$er 2 package.

Refer to Table 21, RTU--MP Controller Inputs and

Outputs, for locations of all connections to the RTU--MP

board.

48TC