Gas heating system, Control circuit, 24--v, General – Carrier 48TC*D08 User Manual

Page 25: Fuel types and pressures

25

Condenser Fan Motor Protection

The condenser fan motor is internally protected against

overtemperature.

Control Circuit, 24--V

The control circuit is protected against overcurrent

conditions by a circuit breaker mounted on control

transformer TRAN. Reset is manual.

GAS HEATING SYSTEM

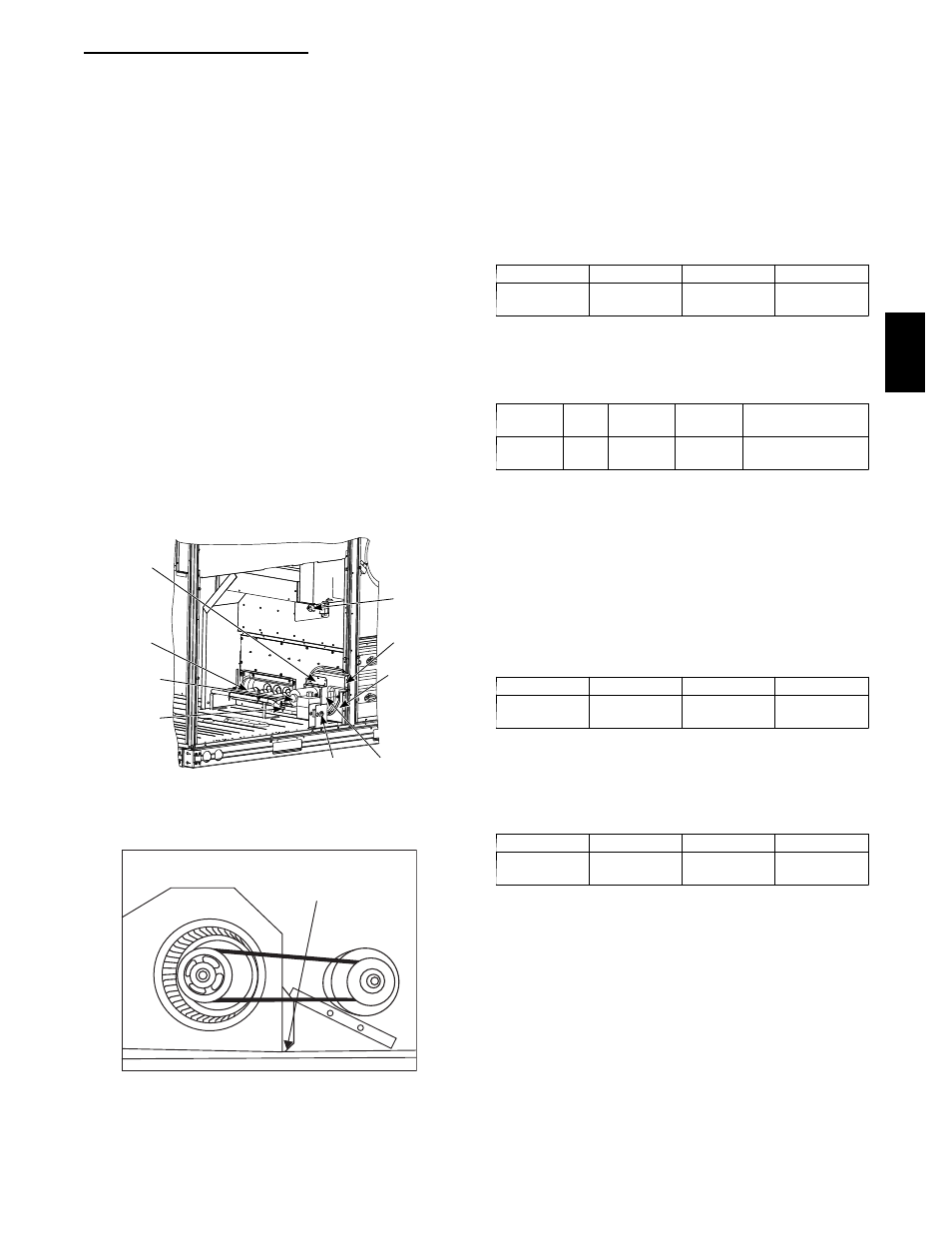

General

The heat exchanger system consists of a gas valve feeding

multiple inshot burners off a manifold. The burners fire

into matching primary tubes. The primary tubes discharge

into combustion plenum where gas flow converges into

secondary tubes. The secondary tubes exit into the

induced draft fan wheel inlet. The induced fan wheel

discharges into a flue passage and flue gases exit out a

flue hood on the side of the unit. The induced draft fan

motor includes a Hall Effect sensor circuit that confirms

adequate wheel speed via the Integrated Gas Control

(IGC) board. Safety switches include a Rollout Switch (at

the top of the burner compartment) and a limit switch

(mounted through the fan deck, over the tubes). (See Fig.

29 and 30.)

INDUCED-

DRAFT

MOTOR

MOUNTING

PLATE

BURNER

SECTION

INDUCED-

DRAFT MOTOR

MANIFOLD

PRESSURE

TAP

ROLLOUT

SWITCH

FLUE

EXHAUST

VESTIBULE

PLATE

BLOWER

HOUSING

GAS

VALVE

C09153

Fig. 29 -- Burner Section Details

Limit Switch

and Shield

C08284

Fig. 30 -- Limit Switch Location

Fuel Types and Pressures

Natural Gas — The 48TC unit is factory--equipped for use

with Natural Gas fuel at elevation under 2000 ft (610 m).

See section Orifice Replacement for information in

modifying this unit for installation at elevations above

2000 ft (610 m).

Gas line pressure entering the unit’s main gas valve must

be within specified ranges. Adjust unit gas regulator valve

as required or consult local gas utility.

Table 5 – Natural Gas Supply Line Pressure Ranges

UNIT MODEL

UNIT SIZE

MIN

MAX

48TC

All

4.0 in. wg

(996 Pa)

13.0 in. wg

(3240 Pa)

Manifold pressure is factory--adjusted for NG fuel use.

Adjust as required to obtain best flame characteristic.

Table 6 – Natural Gas Manifold Pressure Ranges

UNIT

MODEL

UNIT

SIZE

HIGH

FIRE

LOW

FIRE

RANGE

48TC

All

3.5 in. wg

(872 Pa)

1.7 in. wg

(423 Pa)

2.0---5.0 in. wg (Hi)

(498---1245 Pa)

Liquid Propane — Accessory packages are available for

field--installation that will convert the 48TC unit to

operate with Liquid Propane (LP) fuels. These kits include

new orifice spuds, new springs for gas valves and a supply

line low pressure switch. See section on Orifice

Replacement for details on orifice size selections.

Fuel line pressure entering unit gas valve must remain

within specified range.

Table 7 – Liquid Propane Supply Line Pressure Ranges

UNIT MODEL

UNIT SIZE

MIN

MAX

48TC

All

11.0 in. wg

(2740 Pa)

13.0 in. wg

(3240 Pa)

Manifold pressure for LP fuel use must be adjusted to

specified range. Follow instructions in the accessory kit to

make initial readjustment.

Table 8 – Liquid Propane Manifold Pressure Ranges

UNIT MODEL

UNIT SIZE

HIGH FIRE

LOW FIRE

48TC

All

10.0 in. wg

(2490 Pa)

5.0 in. wg

(1245 Pa)

Supply Pressure Switch — The LP conversion kit includes

a supply low pressure switch. The switch contacts (from

terminal C to terminal NO) will open the gas valve power

whenever the supply line pressure drops below the

setpoint. (See Fig. 31 and 32.) If the low pressure remains

open for 15 minutes during a call for heat, the IGC circuit

will initiate a Ignition Fault (5 flashes) lockout. Reset of

the low pressure switch is automatic on rise in supply line

pressure. Reset of the IGC requires a recycle of unit

power after the low pressure switch has closed.

48TC