Exide Technologies Section 92.61 User Manual

Page 8

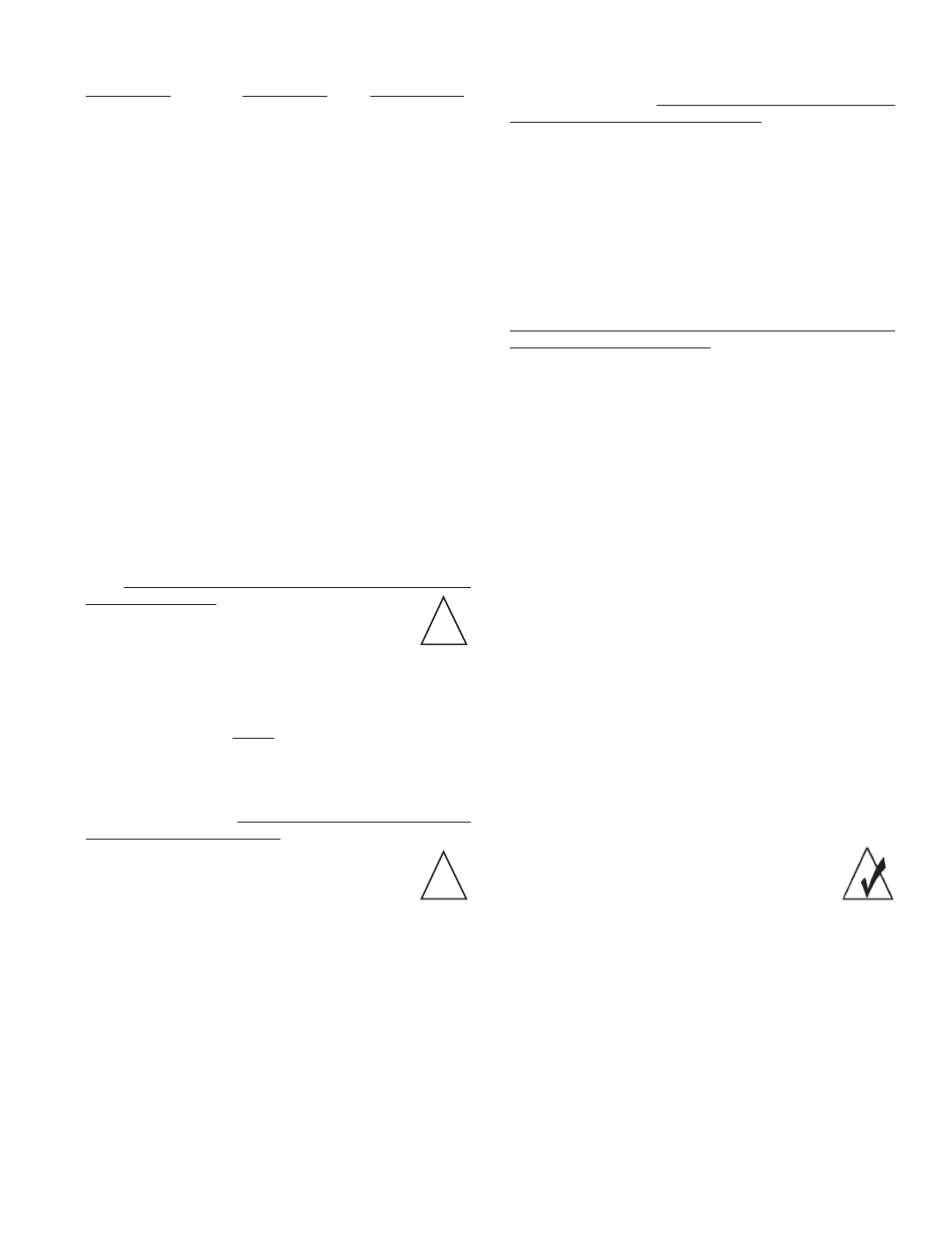

Annual Average

Maximum

Percent

Battery

Battery Reduction

Temperature

Temperature

In Battery Life

77°F (25°C)

122°F (50°C)

0%

86°F (30°C)

122°F (50°C)

30%

95°F (35°C)

122°F (50°C)

50%

104°F (40°C)

122°F (50°C)

66%

113°F (45°C)

122°F (50°C)

75%

122°F (50°C)

122°F (50°C)

83%

For example: If a battery has a design life of 20 years at 77°F

(25°C), but the actual annual average battery temperature is

95°F (35°C), the projected service life of the battery is calcu-

lated to be only 10 years.

Temperature records shall be maintained by the user in accor-

dance with the maintanence schedule published in this manual.

The battery temperature shall not be allowed to exceed the

maximum temperature shown above. It is important to maintain

the battery temperature as close to 77°F (25°C) as possible to

achieve the optimum service life from your battery.

5.3

Temperature Variations

Sources of heat or cooling directed on portions of the battery

can cause temperature variations within the strings, resulting

in cell voltage differences and eventual compromise of battery

performance.

Heat sources such as heaters, sunlight or associated equipment

can cause such temperature variations. Similarly, air condition-

ing or outside air vents may cause cell string temperature varia-

tions. Every effort should be made to keep temperature varia-

tions within 5°F (3°C).

5.4 Ventilation

The Absolyte battery is a Valve Regulated Lead Acid (VRLA)

low maintenance design. Tests have confirmed that under

recommended operating conditions in stationary applications,

99% or more of gases generated are recombined within the

cell. In most cases, no special ventilation and or battery room

is required. Consult your local building and fire codes for

requirements that may apply to your specific location.

Hydrogen and oxygen gases can be vented to the atmosphere

under certain conditions. Therefore, the battery should never be

installed in an air-tight enclosure. Sufficient precautions must be

taken to prevent excessive overcharge.

5.5

Floor Loading

The floor of the area where the battery system is to be

installed should have the capability of supporting the weight

of the battery as well as any auxiliary equipment. The total

battery weight will depend on the cell size, number of cells,

as well as module configuration involved. Prior to installa-

tion, a determination should be made that the floor integrity is

adequate to accommodate the battery system.

5.6

Floor Anchoring

Where seismic conditions are anticipated, floor anchoring

must be implemented.

Where non-seismic conditions are anticipated, anchoring of hori-

zontally stacked systems is recommended for maximum stability.

Four 9/16” (14.3 mm) holes are provided in each I-Beam

support for anchoring. To maintain seismic certification, use

four anchor bolts per horizontal support. Anchor design is the

responsibility of the purchaser/installer.

5.7

Connecting Cables: Battery

System to Operating Equipment

The Absolyte cell is a UL recognized component. Battery

performance is based on the output at the battery terminals.

Therefore, the shortest electrical connections between the

battery system and the operating equipment results in maxi-

mum total system performance.

DO NOT SELECT CABLE SIZE BASED ON CURRENT

CARRYING CAPACITY ONLY. Cable size selection should

provide no greater voltage drop between the battery system

and operating equipment than necessary. Excess voltage drop

will reduce the desired support time of the battery system.

5.7.1 Paralleling

Where it is necessary to connect battery strings in parallel in

order to obtain sufficient load backup time, it is important to

minimize the difference in voltage drop between the battery

strings in parallel in order to promote equal load sharing upon

discharge. Therefore, equal resistance of cable connections

for each parallel string is important. When paralleling multiple

strings to a load or common bus, please follow these guidelines:

• Each parallel string must have the same number of cells

(same string voltage).

• The cables connecting the positive and negative terminals of

each string to the load (or bus) should be of the SAME SIZE

(i.e. same capacity/cross-sectional area).

• The cables connecting the positive and negative terminals

of each string to the load (or bus) should be of the SAME

LENGTH. Choose the shortest cable length that will connect

the battery string that is furthest from the load, and cut all

cables used to connect each string to the load to this same

length.

5.8

Stacking Limitations

There are recommended limits on stacked battery configura-

tions. Please refer to Appendix D for additional information.

NOTE: Horizontal module arrangement only.

5.9

Terminal Plates

Each system is supplied with a terminal plate assembly for

the positive and negative terminations. These should always

be used to provide proper connection to the operating equip-

ment and cell terminals. Any attempt to connect load cables

directly to cell terminal may compromise battery system per-

formance as well as the integrity of cell post seals.

5.10 Grounding

It is recommended that the modules or racks be grounded in

accordance with NEC and/or local codes. See Appendix C for

recommended procedure.

- 4 -

!

!