Exide Technologies Section 92.61 User Manual

Page 16

- 12 -

SECTION 9

9.0 Connections

9.1

Post Preparation

Using either a brass bristle suede shoe brush or 3M Scotch

Brite scouring pad, brighten the flat copper terminal surfaces

to ensure lowest resistance connections.

Apply a thin film of NO-OX-ID “A” grease (supplied with bat-

tery) to all terminal mating surfaces. This will preclude oxida-

tion after connections are completed.

9.2

Connections - System Terminals

Each system is supplied with a terminal plate assembly

for the positive and negative terminations. These should

always be used to provide proper connection to the operating

equipment and cell terminals. Any attempt to connect load

cables directly to cell terminals may compromise battery sys-

tem performance as well as the integrity of cell post seals.

For terminal plate assembly, see Figure 22 (6 cell modules

at low rate) or Figure 23. Consult layout/wiring diagram for

proper kit use. It is recommended that all components be

assembled in place with hardware torqued to 11.3 Newton-

meters (100 in-lbs). Retorque value is also 11.3 Newton-

meters (100 in-lbs).

Refer to Sections 9.1 and 9.3 for electrical contact surface

preparation of terminal plate components.

As shown, terminal plate assembly can be varied to satisfy

module terminal location as well as orientation of terminal

plate in a horizontal or vertical plane. Do not make connec-

tions to operating system at this time.

9.3

Connections - INTER-Module

Consult layout/wiring diagram for correct quantity of lead-

tin plated copper connectors required at each connection.

Follow procedure in Section 9.1 and brighten lead-tin plated

surfaces coming in contact with copper posts. Apply a film

of NO-OX-ID “A” grease to these areas. NOTE: Apply a

minimum amount of grease to cover the surface. As a rule:

“If you can see it, it’s too much”. Where multiple connectors

are required across any single connection, brighten both

sides of connectors along the entire length. Grease these

areas as well. It is recommended when installing connec-

tors that the upper bolts be installed first to reduced risk of

accidental shorting.

Cells are interconnected with connectors and hardware as

shown in Figures 21A and 21B

9.4

Connections - INTER-Stack

Multiple stacks end to end are interconnected as shown in

Figure 21C and 21D. Follow procedures in Section 9.1 and

Section 9.3. Also see Section 9.5, Connections - Torquing.

9.5

Connections - Torquing

When all inter-module connections have been installed, tight-

en all connections to 11.3 Newton-meters (100 in-lbs) Use

insulated tools. All connections should be rechecked after

the initial charge, due to heating during charge.

9.6

Connection - Check

Again, visually check to see that all module terminals are

connected positive (+) to negative (-) throughout the battery.

Also measure the total voltage from terminal plate to terminal

plate. This should be approximately equal to 2.15 volts times

the number of cells in the system, e.g., a 24 cell system

would read: 24 x 2.15v = 51.6 volts.

9.7

Connection Resistance

Electrical integrity of connections can be objectively estab-

lished by measuring the resistance of each connection.

These resistances are typically in the microhm range.

Meters are available which determine connection resistance

in microhms. Be sure that the probes are touching only the

posts to ensure that the contact resistance of connector to

post is included in the reading.

Resistance measurements or microhm measurements

should be taken at the time of installation and annually there-

after. Initial measurements at installation become the bench

mark values and should be recorded for future monitoring of

electrical integrity.

It is important that the bench mark value for all similar con-

nections be no greater than 10% over the average. If any

connection resistance exceeds the average by more than

10%, the connection should be remade so that an accept-

able bench mark value is established.

Bench mark values for connection resistances should also

be established for terminal plates, where used, as well as

cable connections. Bench mark values should preferably be

established upon installation.

All bench mark values should be recorded. Annually, all con-

nection resistances should be re-measured. Any connection

which has a resistance value 20% above its benchmark

value should be corrected.

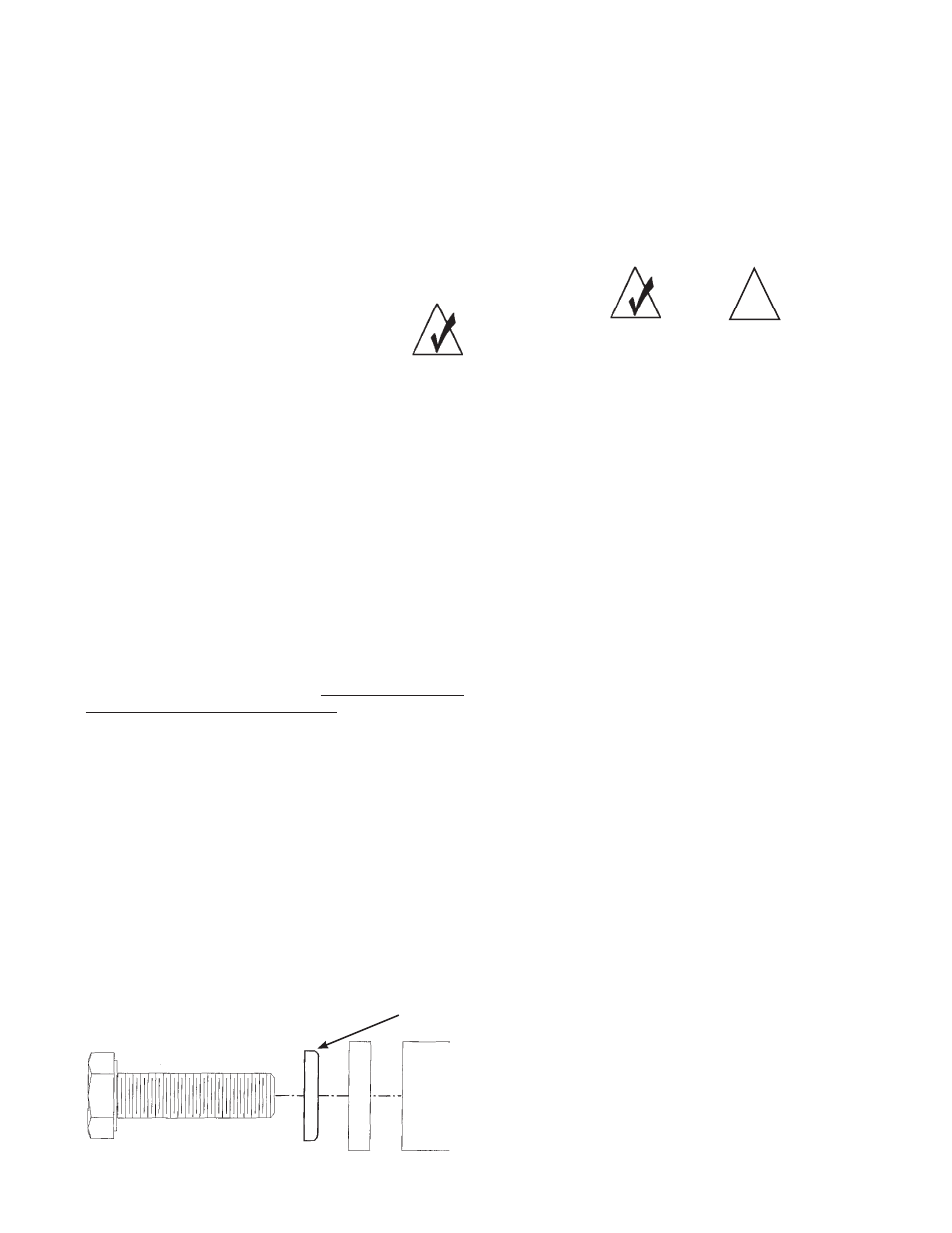

!

WASHERS SHOULD BE INSTALLED WITH THE CURVED

EDGE TOWARD THE CONNECTORS.

BOLT

WASHER CONNECTOR

POST