Exide Technologies Section 92.61 User Manual

Page 12

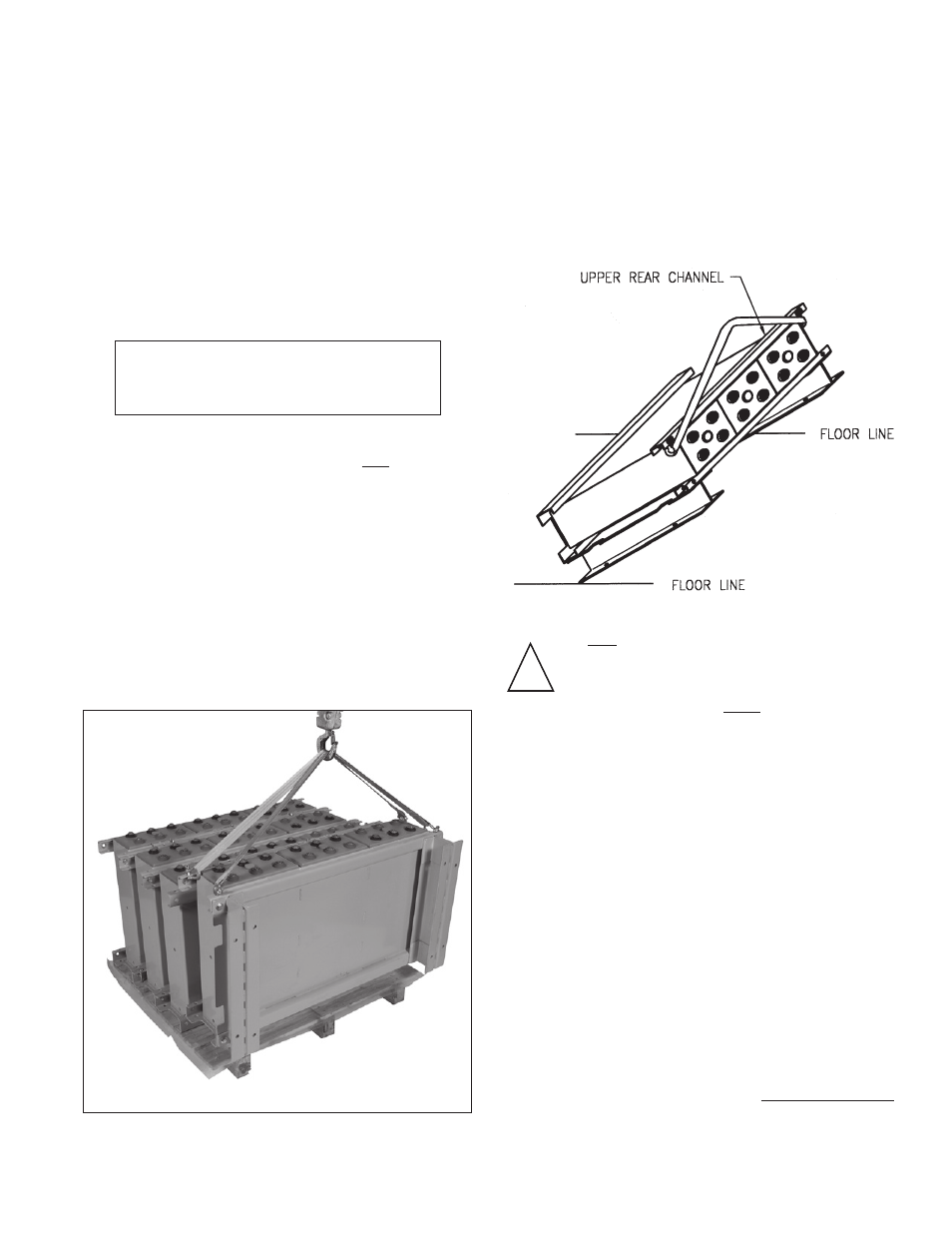

8.1.2 Handling

The module/base support assembly may now be removed

from the pallet using methods outlined in section 6.5,

Handling. Also see Figure 11. Remaining modules may be

removed in a similar manner.

8.1.3 Horizontal Stacking

In order to stack modules in the horizontal position, refer to

Figures 11 thru 13 to perform the tip-over procedure. The

module/base support assembly tip-over should be performed

first. This procedure can be performed using a portable boom

crane or fork lift in conjunction with the lifting straps and lifting

shackles supplied.

CAUTION!

DO NOT ATTEMPT TO PERFORM TIP-OVER OF

MODULE MANUALLY AS SERIOUS PERSONAL

INJURY AND MODULE DAMAGE MAY RESULT.

A. Install lifting strap using lifting shackles in channel base

holes at each end of module upper rear channel as

shown in Figure 12A.

B. Center the lifting hook onto strap and lift until strap is

under tension and raises bottom of module from floor

surface so that upper and lower diagonal corners are in a

vertical mode.

C. While exerting manual force on the upper rear of module,

lower hoist until module is in horizontal position.

See Figures 12B and 13.

D. When module is horizontal, install the four lifting shackles

and two lifting straps as shown in Figure 14.

E. Where floor anchoring is required, position module/base

assembly in desired location. Mark floor through I-beam

holes and remove module/base assembly. Install floor

anchoring and reposition module/base assembly over

anchoring. Prior to installing nuts and washers, check that

assembly is level in both axes. Level using shims pro-

vided. Torque anchor hardware to manufacturer’s recom-

mended value.

NOTE:

1) One strap with shackles used for tip-over

procedure.

2) Observe channel hole used as well as direction of

shackle insertion.

3) Tip over procedure for single modules only.

TIP OVER PROCEDURE

SHACKLE-STRAP USAGE

Figure 12A

F. Using Steps A-D and the layout/wiring diagram, position

the next module on top of first so that channels of each

mate with one another using drift pins to align channel

holes. Make sure channel ends and sides of the upper

and lower modules are flush. Install serrated flange bolts

and nuts in open holes, finger tight. Remove lifting straps.

Use leveling shims to fill gaps between trays. See Figures

15, 16, and 17A.

G. At this time, check to see that the first two modules are

plumb front to back and side to side using wooden or

plastic level together with plywood straight edge. This is

to insure proper alignment for module interconnection

later on. Torque hardware to 47 Newton-meters

(35 Ft-Lbs).

- 8 -

HANDLING MODULE - BASE SUPPORT ASSEMBLY

Figure 11

!