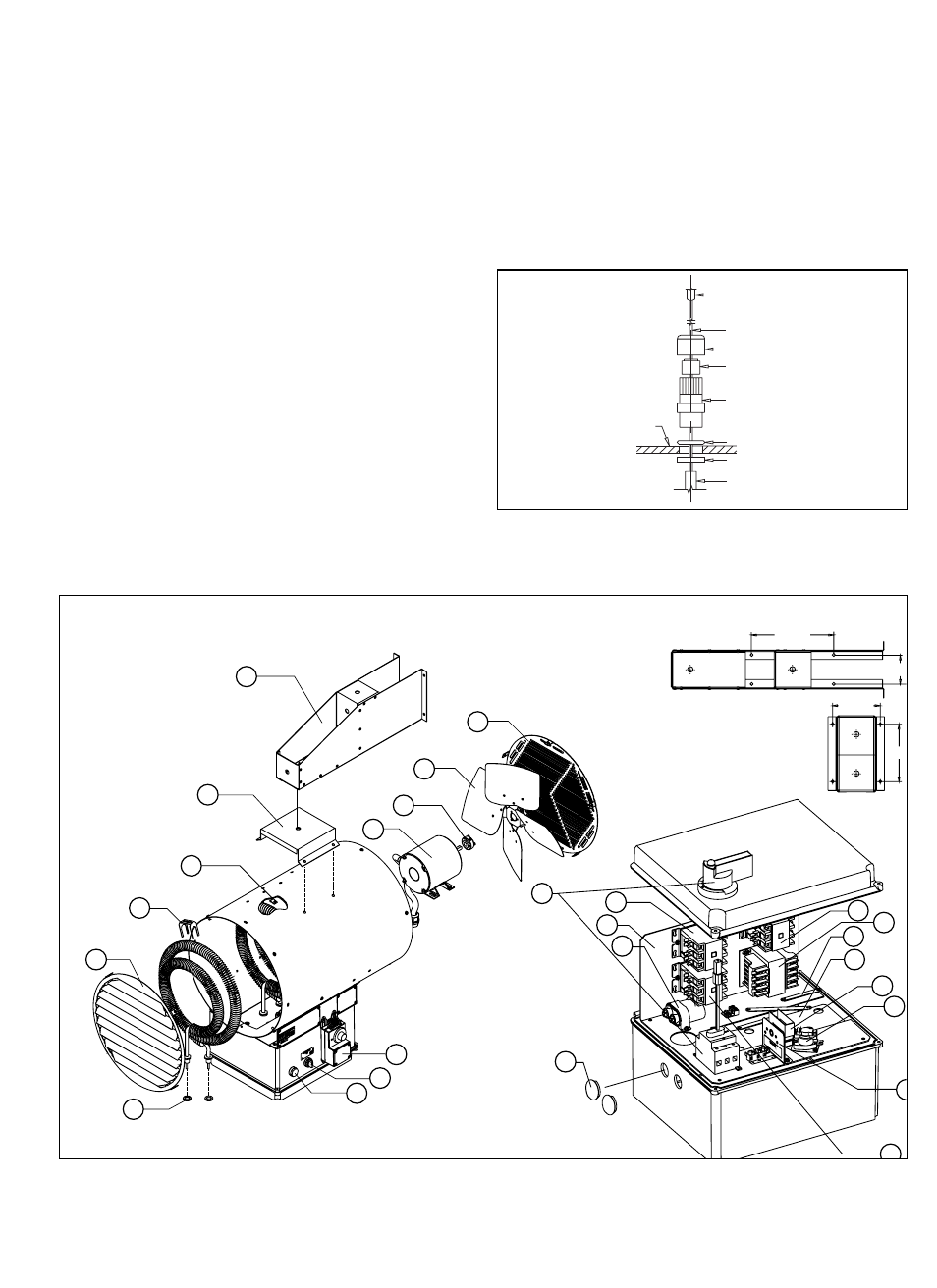

Parts diagram – CCI Thermal Technologies CR1 - Trito Corrosion-Resistant Washdown Unit Heater User Manual

Page 6

10

7

3

12

15

14

13

8

5

4

11

9

2

WALL MOUNT

BRACKET DETAIL

217.0

126

126.0

152

2

2

1

19

6

22

21

17

20

26

20

23

25

PARTS DIAGRAM

TEMPERATURE HIGH-LIMIT

1. Remove discharge grill from heater. Remove clips

securing bulb and capillary to cabinet.

2. Inside electrical enclosure, remove lock nut from

high-limit compression fitting and remove fitting from

enclosure.

3. Remove compression nut from the fitting (see Figure

11). Remove seal from fitting. Remove fitting from

capillary.

4. Remove high-limit switch from the enclosure.

5. Replace high-limit with factory-supplied replacement

high-limit.

6. Reinstall high-limit switch to bracket in the control

enclosure.

7. Slip capillary sleeve over capillary.

Note: For 25 to 39 kW heaters, the sleeve must be cut

to 8.25 in. (210 mm). For 15 and 20 kW heaters, the

sleeve must be cut to 14.125 in. (360 mm). For 3 to

10 kW heaters, sleeve does not have to be cut to

length.

8. Slide lock nut over bulb and capillary. Insert bulb and

capillary through the enclosure opening.

9. Place compression fitting body over capillary. Install

seal on capillary and insert seal into body of fitting

(see Figure 11).

10. Loosely install top nut onto compression seal body.

Secure fitting to enclosure with lock nut on the inside

of the enclosure. Tighten lock nut to ensure watertight

seal.

11. Reinstall the bulb and capillary using the original

clips. Ensure the bulb is in the same position as the

previous high-limit. The bulb tip should be 3.94 in.

(100 mm) from the discharge edge of the cabinet.

12. Tighten top nut on compression seal.

BULB

CAPILLARY

NUT

SEAL

COMPRESSION

FITTING BODY

O-RING

CABINET

LOCKNUT

SLEEVE

– 6 –

Figure 11

Figure 12