CCI Thermal Technologies PMK - Pipe Mounting Kit User Manual

Installer required to supply, Contents item qty. description, Step 1

Pipe Mounting Kit Installation Instructions

For Electric Heaters

WARNING:

If the heater is installed on a structure that is to be transported, provide additional support for the

heater during transit. The suspended weight should not exceed 300lbs (136kg).

Refer to the owner’s manual for mounting specifications and conditions.

Check that your heater model number corresponds to the model number shown on the mounting kit carton

.

Installer required to supply:

a)

One piece of 3”, Schedule 40 or heavier, steel pipe cut to required length. Maximum length to be 25ft (7.6m).

b)

A method to fasten the Column Stabilizer

Bracket to the supporting structure. Four 3/8” diameter grade 5 bolts are

suggested, however, any method providing the same or greater strength may be used.

c)

A fastener to attach the Base Plate

to a steel or wood floor. The kit provides a 3/8 UNC Expansion Bolt for concrete

floors.

CONTENTS

Item Qty. Description

1

Mtg Attach Assy Bracket

1

Arm Assembly

1

Stabilizer Angle

1

Column Stabilizer Bracket

1

Base Plate

2

Bolt, 1/2 UNC x 1-1/4

8

Lock Washer, 3/8”

3

Lock Washer, 1/2”

3

U-Bolt, 3/8 UNC x 3-1/2

2

Bolt, 3/8 UNC x 1

1

Expansion Bolt, 3/8 UNC x 2-3/4

9

Nut, 3/8 UNC

5

Flat Washer, 3/8”

2

Nut, 1/2 UNC

1

Flat Washer, 5/8”

1

Bolt, 5/8 UNC x 1-1/4

1

Lock Washer, 5/8”

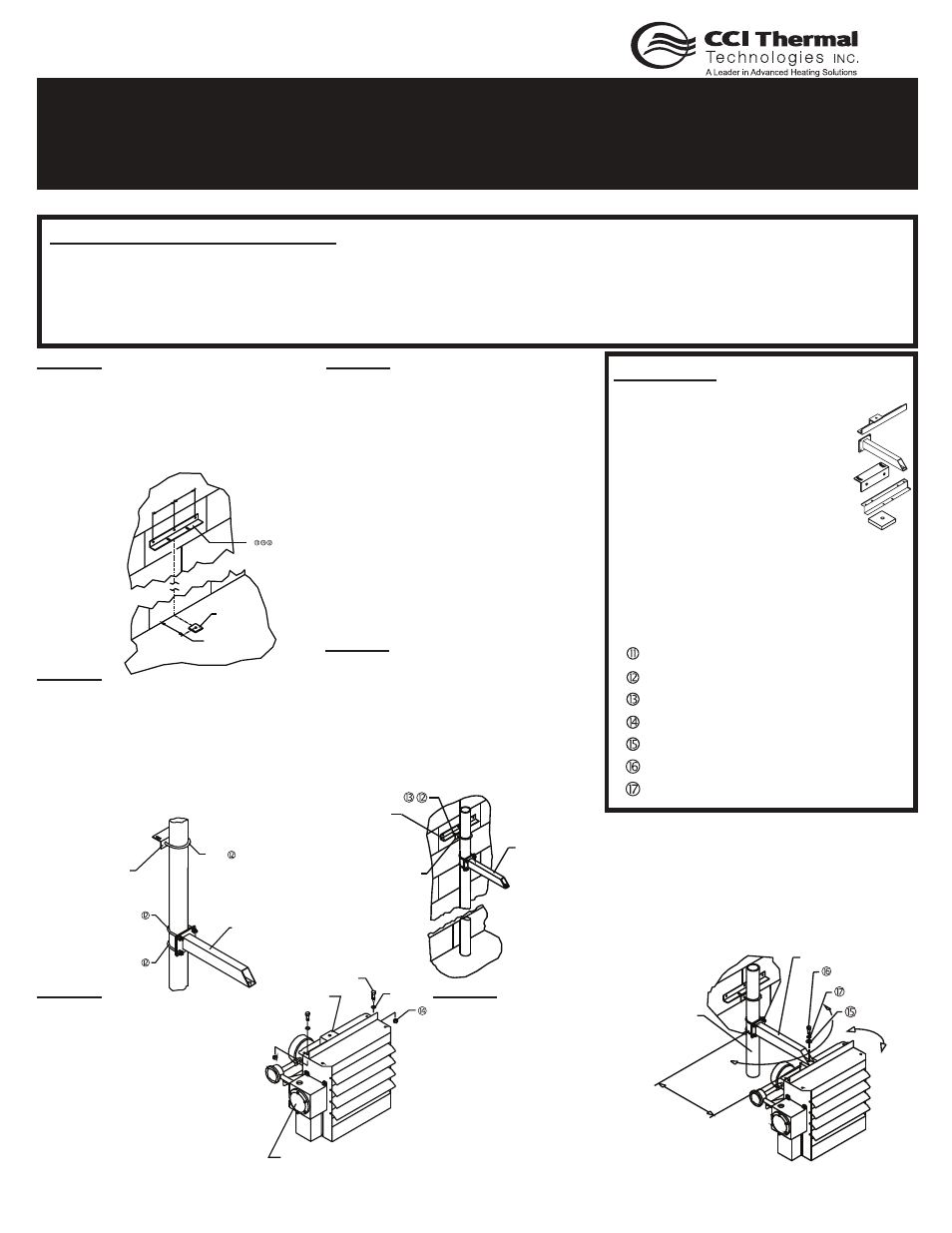

STEP 1

Fasten Column Stabilizer Bracket

to the wall using the installer supplied

fastening method. The Column

Stabilizer Bracket must be mounted at

an appropriate height to support the top

of the pipe.

Printed in Canada. Copyright 2007. All rights reserved.

Part No. 5750-2

STEP 2

Install the Base Plate centered below

the Column Stabilizer Bracket

using installer supplied fasteners,

or the supplied 3/8 UNC x 2-3/4

expansion bolt, washer and 3/8 UNC

nut. To install the expansion bolt, drill a

3/8”(9.5mm) diameter hole a minimum

of 2” (51mm) deep. Screw the nut with

a washer onto the bolt, 1/8” (3mm)

past the end. Drive the bolt through the

base plate hole into the drilled hole so

that the nut and washer are seated on

the Base Plate

. Turn nut until tight.

STEP 3

Using U-bolts, lock washers, and 3/8

UNC nuts, fasten Stabilizer Angle

and Arm Assembly

at their

approximate final location on the 3”

steel pipe. Leave nuts loose enough

to permit parts to be moved to a final

location after pipe is erected.

STEP 4

Erect the pipe on Base Plate

. Using

two 3/8 UNC x 1 bolts, two flat washers

per bolt, lock washers and 3/8 UNC

nuts, fasten Stabilizer Angle

to

Column Stabilizer Bracket

. Position

Arm Assembly

at final mounting

height and tighten all U-bolts.

STEP 5

Bolt Mtg Attach Assy Bracket

to the heater using 1/2 UNC x

1-1/4 bolts, lock washers, and

1/2 UNC nuts. Mtg Attach Assy

Bracket must be placed with

the threaded hole closest to the

control enclosure side of the

heater.

STEP 6

Lift the heater into place and

fasten it to the Arm Assembly

using a 5/8 UNC x 1-1/4

bolt, lock washer, and flat

washer. This step will require

more than one person due to

the weight of the heater. Refer

to the owner’s manual for the

weight of the heater.

Hole C

en

ter Line

3-3/4" to 4-7/8"

(96-124mm)

8”

(203mm)

8”

(203mm)

Control Enclosure

3” Sch. 40

steel pipe 25ft (7.6m)

max. length

Pipe

Center Line

Heater

Pivot

Point

21”

(534mm)

Heater

and arm

assembly

may be

rotated, as

indicated

by arrows.