CCI Thermal Technologies CA - Stuffing Box User Manual

Ca1001 stuffing box, Installation instructions

CA1001 STUFFING BOX

INSTALLATION INSTRUCTIONS

E-mail: [email protected]

www.ccithermal.com

MI167.Rev.7.01

Date of Issue: January 2013

Factory:

2721 Plymouth Drive, Oakville, Ontario, Canada L6H 5R5

Telephone: (905) 829-4422 Fax: (905) 829-4430

Toll Free: 1-800-410-3131

ISO 9001

Printed In Canada

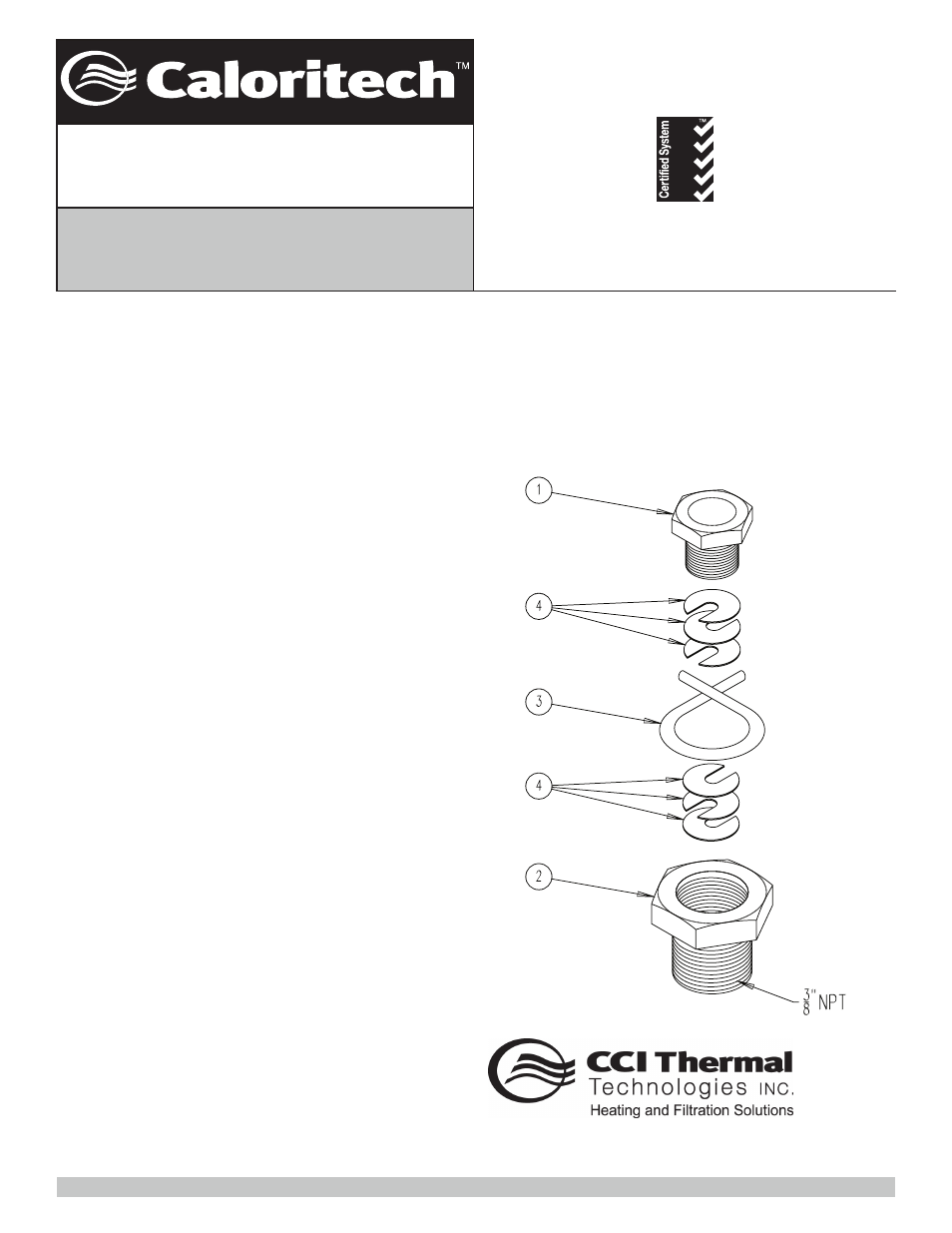

Fig.1

1.0

APPLICATION

1.1 The CA1001 is used around the capillary tube of an

AR or ARC control to hold the bulb into a well, or seal the

bulb into a tank.

1.2 AR thermostats with style 4 bulbs include a factory

installed non-removable stuffing box that may make the

use of a CA1001 unnecessary. AR thermostats style 9,

ARC limits and all thermostats and limits with optional

moisture resistant and explosion resistant enclosures

will require the CA1001 stuffing box if used as described

in 1.1.

1.3 It is always advisable to use a thermostat well where

high pressures, corrosive material or high or varying flows

are involved. Without a well, a leak or defect in the

thermostat would necessitate shutting down and drain-

ing the system. However, it should be noted that the use

of well may slow down the response time and increase

controller differential.

2.0

INSTRUCTION

2.1 The parts included with this kit are shown in Fig. 1.

2.2 Slide the small brass bushing over the bulb and onto

the capillary and position out of the way. The hex should

be towards the control and threads towards the bulb.

2.3 Slide the large brass bushing over the bulb positioned

with the hex facing the control.

2.4 Drop 3 split washers around the capillary and down

into the hollow of the large compression fitting.

It is very

important for a liquid light seal that the slots are

positioned alternately 180° from each other per Fig. 1.

2.5 Wrap the 5" graphite impregnated cord tightly around

the capillary and push it tightly into the compression fitting

hollow with a blunt tool being careful not to damage the

capillary.

2.6 Put at least one split washer in place and temporarily

thread the small bushing into place inside the large bush-

ing. This will help to compact the cord into a liquid tight

seal. Remove the small bushing, add the remaining 2

split washers again being sure to stagger the slots 180°

apart and reinstall the small bushing semi tight.

2.7 Position the assembly to the correct position on the

capillary, tighten the large bushing into its mounting

position in the tank or process, then tighten down the

small bushing to ensure a liquid tight seal.

2.8 If using the stuffing box assembly for mechanical

holding only in an air system or in a thermostat well the

extra care of assembly described in 2.4 thru 2.6 is not as

critical.

1.0 APPLICATION

1.1 The CA1001 is used around the capillary tube of an AR or

ARC control to hold the bulb into a well, or seal the bulb

into a tank.

1.2 AR thermostats with style 4 bulbs include a factory

installed non-removable stuffing box that may make the

use of a CA1001 unnecessary. AR thermostats style 9,

ARC limits and all thermostats and limits with optional

moisture resistant and explosion resistant enclosures will

require the CA1001 stuffing box if used as described in

1.1.

1.3 It is always advisable to use a thermostat well where high

pressures, corrosive material or high or varying flows are

involved. Without a well, a leak or defect in the thermostat

would necessitate shutting down and draining the system.

However, it should be noted that the use of well may

slow down the response time and increase controller

differential.

2.0 INSTRUCTION

2.1 The parts included with this kit are shown in Fig. 1.

2.2 Slide the small brass bushing over the bulb and onto the

capillary and position out of the way. The hex should be

towards the control and threads towards the bulb.

2.3 Slide the large brass bushing over the bulb positioned with

the hex facing the control.

2.4 Drop 3 split washers around the capillary and down

into the hollow of the large compressing fitting. It is very

important for a liquid light seal that the slots are positioned

alternately 180° from each other per Fig.1.

2.5 Wrap the 5” graphite impregnated cord tightly around the

capillary and push it tightly into the compression fitting

hollow with a blunt tool being careful not to damage the

capillary.

2.6 Put at least one split washer in place and temporarily

thread the small bushing into place inside the large

bushing. This will help to compact the cord into a liquid

tight seal. Remove the small bushing, add the remaining

2 split washers again being sure to stagger the slots 180°

apart and reinstall the small bushing semi tight.

2.7 Position the assembly to the correct position on the

capillary, tighten the large bushing into its mounting

position in the tank or process, then tighten down the

small bushing to ensure a liquid tight seal.

2.8 if using the stuffing box assembly for mechanical holding

only in an air system or in a thermostat well the extra care

of assembly described in 2.4 thru 2.6 is not as critical.