Electrical, Warning, General – CCI Thermal Technologies CR1 - Trito Corrosion-Resistant Washdown Unit Heater User Manual

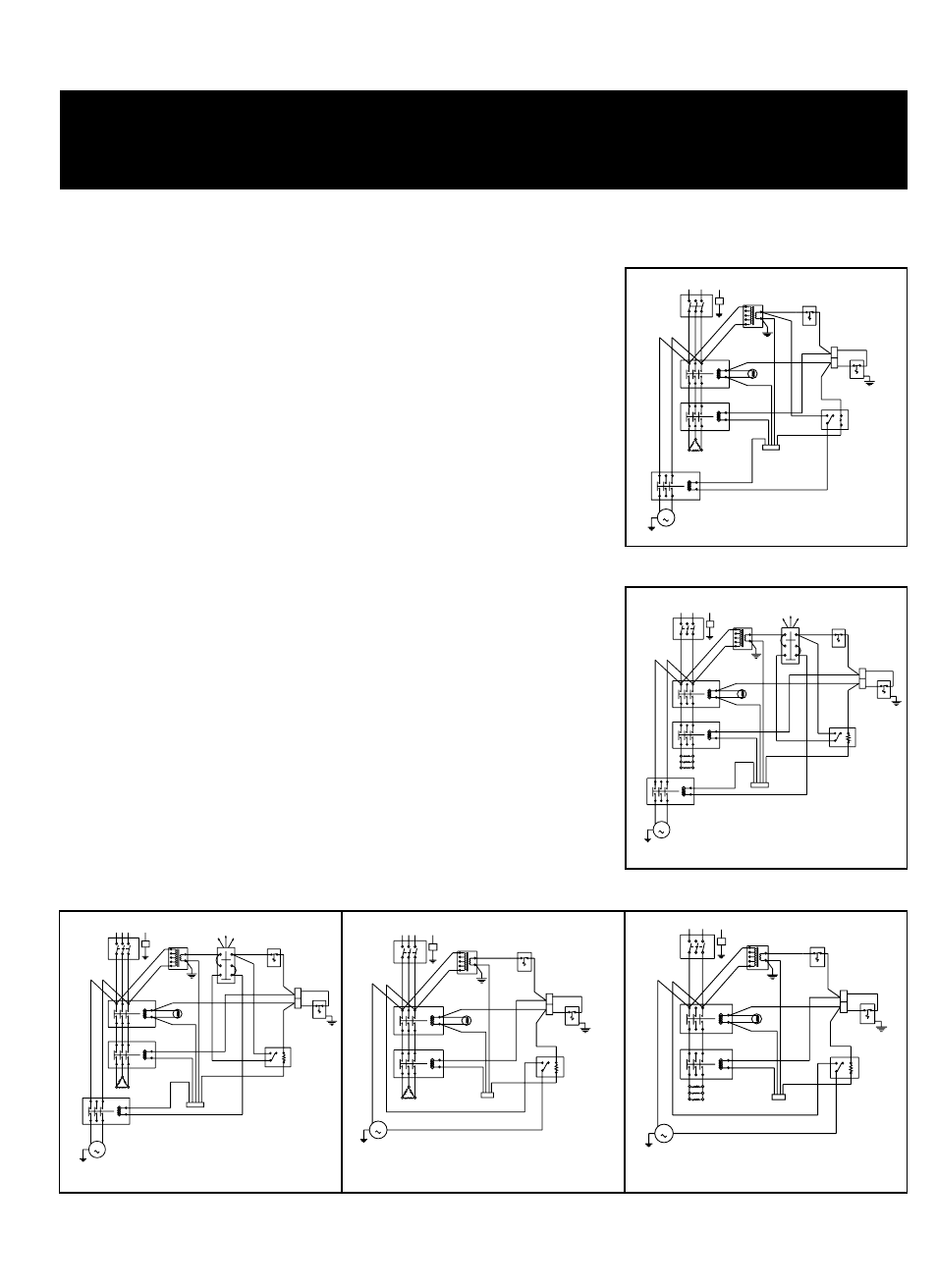

Page 4: Field wiring, Final inspection, Figure 7 figure 8 figure 5 figure 6, Figure 4

TRANSFORMER

120V

TEMPERATURE

HIGH-LIMIT

ELEMENTS

REDUNDANT

CONTACTOR

ELEMENT

CONTACTOR

OPTIONAL

PILOT

LIGHT

T1

T2

ROOM

THERMOSTAT

FAN DELAY

2

1

3

NO NC

MOTOR

OPTIONAL

DISCONNECT

SWITCH

G

G

FIELD CONNECTIONS

L1

L2

ELEMENTS

REDUNDANT

CONTACTOR

ELEMENT

CONTACTOR

OPTIONAL

PILOT

LIGHT

TRANSFORMER

120V

3 POSITION SWITCH

ON

OFF

A & C

A

A

C

T1

T2

C

B

B

B

FAN ONLY

TEMPERATURE

HIGH-LIMIT

ROOM

THERMOSTAT

FAN DELAY

2

3

NO NC

1

MOTOR

CONTACTOR

MOTOR

OPTIONAL

DISCONNECT

SWITCH

FIELD CONNECTIONS

L1

G

G

L2 L3

ELECTRICAL

WARNING

Disconnect the power supply before installation of the heater. Lock the switch in

the “OFF” (open) position and/or tag the switch to prevent unexpected power application.

Installation and wiring of the heater must adhere to all applicable codes.

T1

T2

FAN DELAY

ELEMENTS

REDUNDANT

CONTACTOR

ELEMENT

CONTACTOR

OPTIONAL

PILOT

LIGHT

ROOM

THERMOSTAT

2

1

3

NO NC

MOTOR

TRANSFORMER

120V

AUTO RESET

HIGH-LIMIT

OPTIONAL

DISCONNECT

SWITCH

G

G

FIELD CONNECTIONS

L1

L2

MOTOR

CONTACTOR

(MANUAL RESET

OPTIONAL)

TRANSFORMER

120V

3 POSITION SWITCH

ON

OFF

A & C

B

A

C

B

A

C

B

FAN ONLY

TEMPERATURE

HIGH-LIMIT

ELEMENTS

REDUNDANT

CONTACTOR

ELEMENT

CONTACTOR

OPTIONAL

PILOT

LIGHT

T1

T2

ROOM

THERMOSTAT

FAN DELAY

2

1

3

NO NC

MOTOR

CONTACTOR

MOTOR

OPTIONAL

DISCONNECT

SWITCH

G

G

FIELD CONNECTIONS

L1

L2

Single phase without

3-position switch

Single phase with

3-position switch

– 4 –

Figure 7

Figure 8

Figure 5

Figure 6

GENERAL

1.

Use only copper conductors and approved Type 4X wiring

methods during installation. Refer to the “Technical Data” table

for the voltage, amperage and wattage ratings when sizing for the

appropriate conductors.

2.

Supply voltage is to be within 10% of the data plate voltage.

3.

External over-current protection is required and must meet data

plate ratings for voltage, amperage and frequency.

FIELD WIRING

1.

Heater is supplied with an enclosure that has 2 standard

3/4" trade size conduit openings to accommodate the line conductors or

external thermostat connection.

2.

Heater may be supplied with a factory-installed built-in room thermostat.

On heaters not supplied with this option, a remote thermostat is required.

Connect the remote thermostat conductors to the terminal block marked

T1, T2 and Ground. Any thermostat used with this heater must be:

a) Listed or Approved

b) Type 4X rated*, and

c) Rated at 120 volt minimum and 5 amp minimum.

*An appropriate Type 4X rated room thermostat is available from

the factory.

FINAL INSPECTION

1.

Before application of electrical power:

a) check that all connections are secured and comply with the applicable

code requirements,

b) confirm that the supply voltage is compatible with the data

plate specifications,

c) remove any foreign objects from the heater,

d) ensure all external fittings and enclosure covers are secured,

e) ensure that the fan rotates freely, and

f) if equipped, ensure manual reset high-limit has been reset.

Figure 4

TRANSFORMER

120V

TEMPERATURE

HIGH-LIMIT

ELEMENTS

REDUNDANT

CONTACTOR

ELEMENT

CONTACTOR

OPTIONAL

PILOT

LIGHT

T1

T2

ROOM

THERMOSTAT

FAN DELAY

2

1

3

NO

NC

MOTOR

OPTIONAL

DISCONNECT

SWITCH

G

G

FIELD CONNECTIONS

L1 L2 L3

Three phase with

3-position switch

208, 240, 480 volt three phase models

without 3-position switch

Three phase without

3-position switch

600 volt models