Viking Pump TSM341.1: SG Mag Drive Series User Manual

Page 9

SECTION TSM 341.1

ISSUE

J

PAGE 9 OF 19

SG-804, -805 & -807

PUMP DISASSEMBLY

Before attempting to repair the pump, make sure that all of

the details covered in “

TROUBLESHOOTING” on page 16

have been checked out because disassembly of a good

pump should be avoided. Due to pump construction and close

tolerances used in the pump manufacture, repair is seldom

economically feasible, unless it is an O-ring or such. Often

when some internal part wears such as a bushing, shaft or

gear, it will cause excessive wear in other mating parts. In

this case more components will be required to rebuild the

pump back to original condition than originally expected.

Replacement parts are only available as displayed in the

table of parts (

Figure 14 & Figure 15, Table 3). Contact

your local distributor to obtain replacement parts. Be sure

to supply the pump model number and serial number.

Mark all sections of the pump during disassembly to ensure

they will be reassembled in the proper order and orientation.

Note: The pump must be separated from coupling to

disassemble (See “

COUPLING DISASSEMBLY” on page 7).

1. Remove the assembly capscrews (item 8, Figure 14

or 15).

2. Remove the key and the second retaining ring from the

driver shaft.

3. The pump is now held together only by the alignment

sleeves. Hold the head of the pump and gently tap on

the sides of the pump bracket with a soft face hammer,

alternating sides of the pump. This should slowly

separate the sections. Do not hit the sections hard or

use a screwdriver to pry them apart as this may damage

the mating surfaces.

4. After the pump is apart, inspect all parts for signs of

wear. Look carefully at the shaft, bushings, inside of

casing, gear teeth, and the flat sections that are located

on each side of the casing for sign of wear.

5. Visually inspect the bracket O-ring but do not remove

it unless planning to replace, especially if it is an

encapsulated O-ring. If the O-ring located between the

sections are PTFE (appear to be white), it is strongly

recommended to replace rather than reuse.

6. Remove the acorn nut covering the relief valve adjusting

screw. Measure the distance of the relief valve adjusting

screw to the pump surface and record its length. Finish

disassembling the relief valve and inspect the seat in the

head and the poppet for signs of wear or foreign matter

on either surface.

SG-804, -805 & -807

PUMP ASSEMBLY

•

The pump is ready to be reassembled after all parts

have been changed and worn parts replaced.

•

Use a suitable lubricant compatible with the fluid being

handled when reassembling the pump.

•

Make sure all holes machined in the bracket are clean

and that the mating surfaces of each section are free of

any dents or burrs. Make sure the hole in the end of the

shaft is unrestricted.

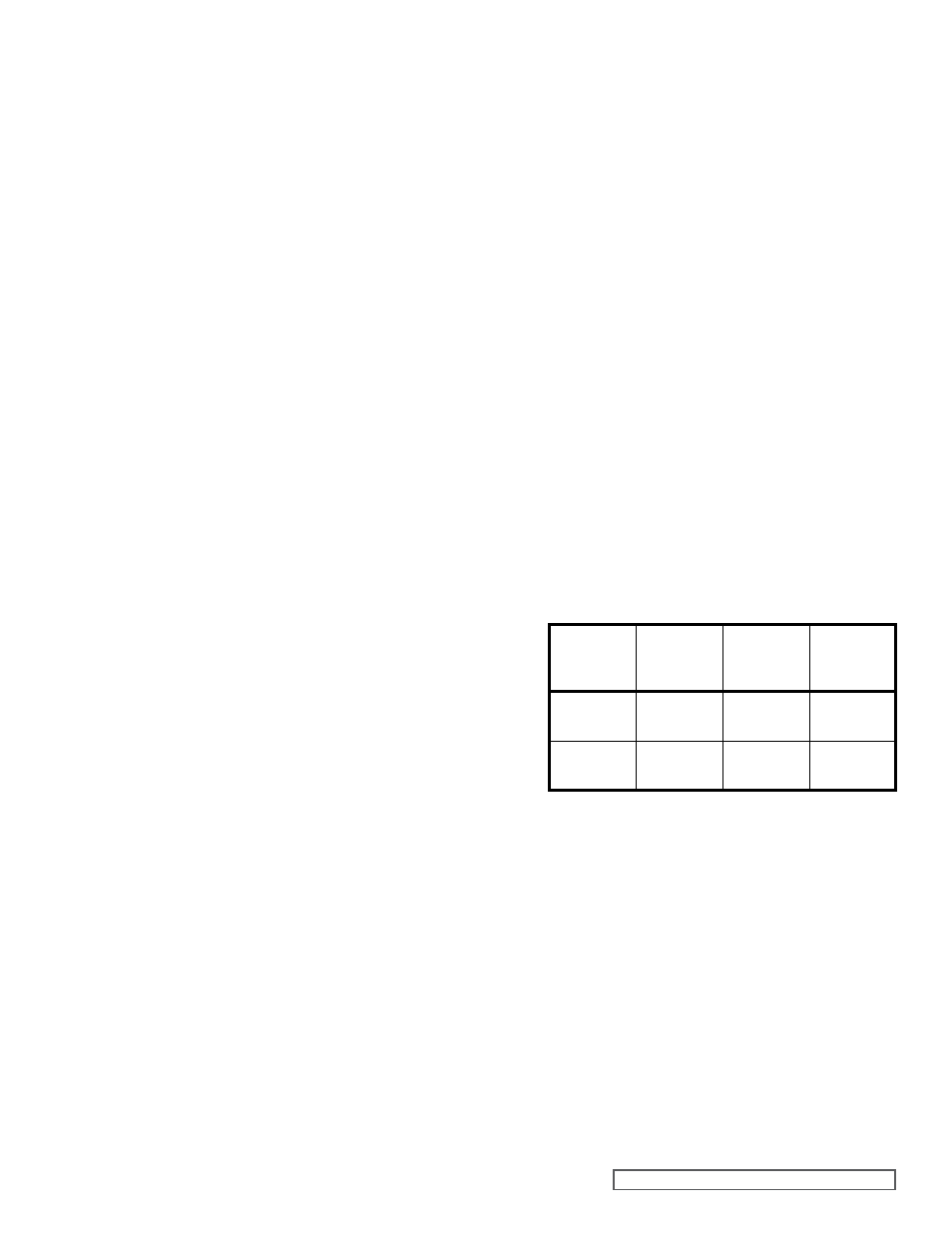

MODEL

BOLT SIZE

QUANTITY

TORQUE

SPEC.

(FT-LB)

SG-804

SG-805

¼

2

7-9

SG-807

½

4

50-55

6. Reassemble the relief valve, setting the adjusting

screw to the previous dimension. Place the gasket

onto the adjusting screw holding the adjusting screw

while tightening the locknut. Recheck the dimension,

install the second gasket on other side of the locknut

and install the acorn nut.

7. Install the drive key into the drive shaft keyset and the

inner retaining ring into the groove closest to the pump

bracket.

1. Install the bracket O-ring. If it is encapsulated (purple or

orange appearance) then follow the special instructions

below.

Do not attempt to reuse this type of O-ring if it has been

removed. Immerse a new O-ring in boiling water for

a few minutes. Remove from water and stretch out in

hands so it will fit onto the bracket hub without forcing

over a sharp edge. When in place, run hot water over

O-ring until it shrinks down tight into the hub O-ring

groove. Dry the area with compressed air.

2. Place head down on flat surface with the O-ring groove

up and place the O-ring into the groove. Install the

alignment sleeves in proper holes by tapping with soft

face hammer.

3. Slide the next section onto the alignment sleeves,

whether it is a separation plate or a casing and install

another O-ring. The pump may require more than one

pair of alignment sleeves: add additional pairs when

necessary.

4. After the casing is installed, place the driver and driven

gears and shaft into the proper positions (refer to

Figure 14 & 15) for proper positioning of driver and

driven shaft assemblies.

5. After installing the casing, there should be a short

length of alignment sleeve projecting out to line up

the bracket. Install the final O-ring between sections;

lubricate the gears and shafts, then slide the bracket

into place. Turn the pump on its side and insert

assembly capscrew and tighten each capscrew until

finger tight. Tighten with torque wrench as specified

below: