Md2-b & md2-c coupling pump removal, Caution – Viking Pump TSM341.1: SG Mag Drive Series User Manual

Page 11

SECTION TSM 341.1

ISSUE

J

PAGE 11 OF 19

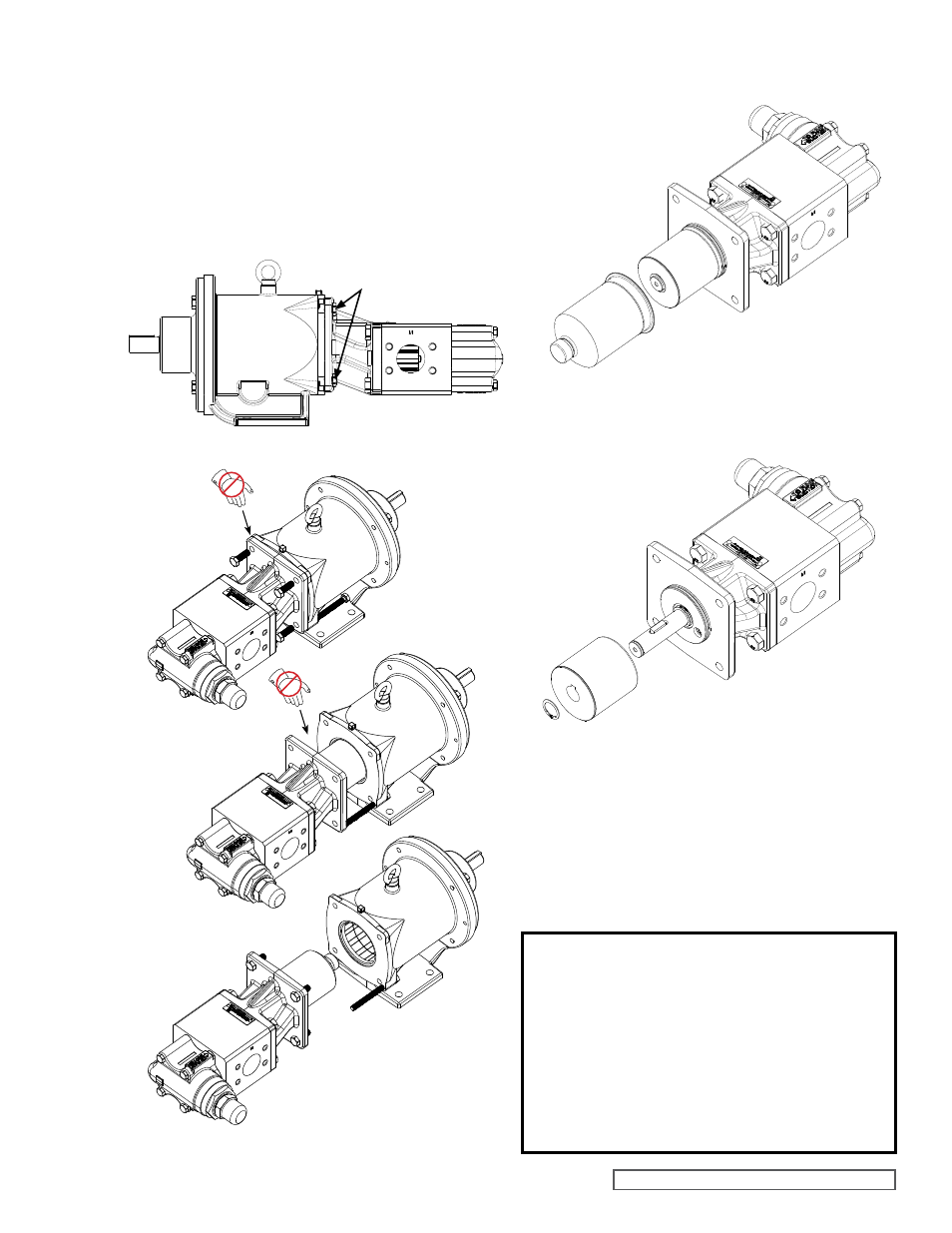

FIGURE 18

PUMP AND BRACKET SEPARATION SEQUENCE

MD2-B & MD2-C COUPLING

PUMP REMOVAL

Read all of the instructions before proceeding with

disassembly of the coupling and/or pump.

1. Remove the piping to the ports and remove the

capscrews securing the pump to the bracket. Support

the pump with an overhead hoist if possible. Use the M10

x 120 capscrew (jackscrew) in the bracket to separate

the inner magnet from the outer. (See

Figure 18).

CAUTION !

Use extreme caution, when pulling the inner

magnet away from the outer magnet (see

Figure 18). Do not place your fingers between

the pump mounting flange and the face of

the bracket. If you do not completely pull the

pump out it will snap back and could pinch

a finger or hand. Once the inner magnet is

removed from the bracket be careful setting it

down as it will attract any iron or steel object.

2. The canister will contain some liquid, therefore use care

while removing from the pump and pull it straight off. See

Figure 19.

FIGURE 17

3. Remove the external snap ring (closest to end of shaft)

and slide off the inner magnet assembly (See

Figure

20). Use caution, as this is a very strong magnet.

4. Do not remove the canister O-ring unless it is damaged,

especially if it is PTFE (Derivative) Encapsulated. If a

new O-ring is required, follow instructions in the

PUMP

ASSEMBLY section, page 12.

5. You should be able to visually inspect the outer magnets

from the end of the bracket. If removal is necessary,

start by removing the (4) capscrews and separating the

bracket from the motor or bearing carrier (See

Figure 12,

page 7). Loosen setscrews in outer magnet assembly to

pull assembly off shaft.

FIGURE 19

CANISTER REMOVAL

FIGURE 20

INNER MAGNET REMOVAL

BRACKET

CAPSCREWS (4)