Md2-b bearing carrier assembly, Md2-c bearing carrier assembly, Danger – Viking Pump TSM341.1: SG Mag Drive Series User Manual

Page 15

SECTION TSM 341.1

ISSUE

J

PAGE 15 OF 19

DANGER !

Be certain that the driving means (motor,

turbine, engine, etc.) has been “locked out”

or made non-operational so that it cannot be

started while work is being done on pump.

1.

Inspect the magnets for any steel objects, which may be

attached. Remove any foreign material. If using bearing

carrier assembly option, please see specific assembly

instructions on page 15.

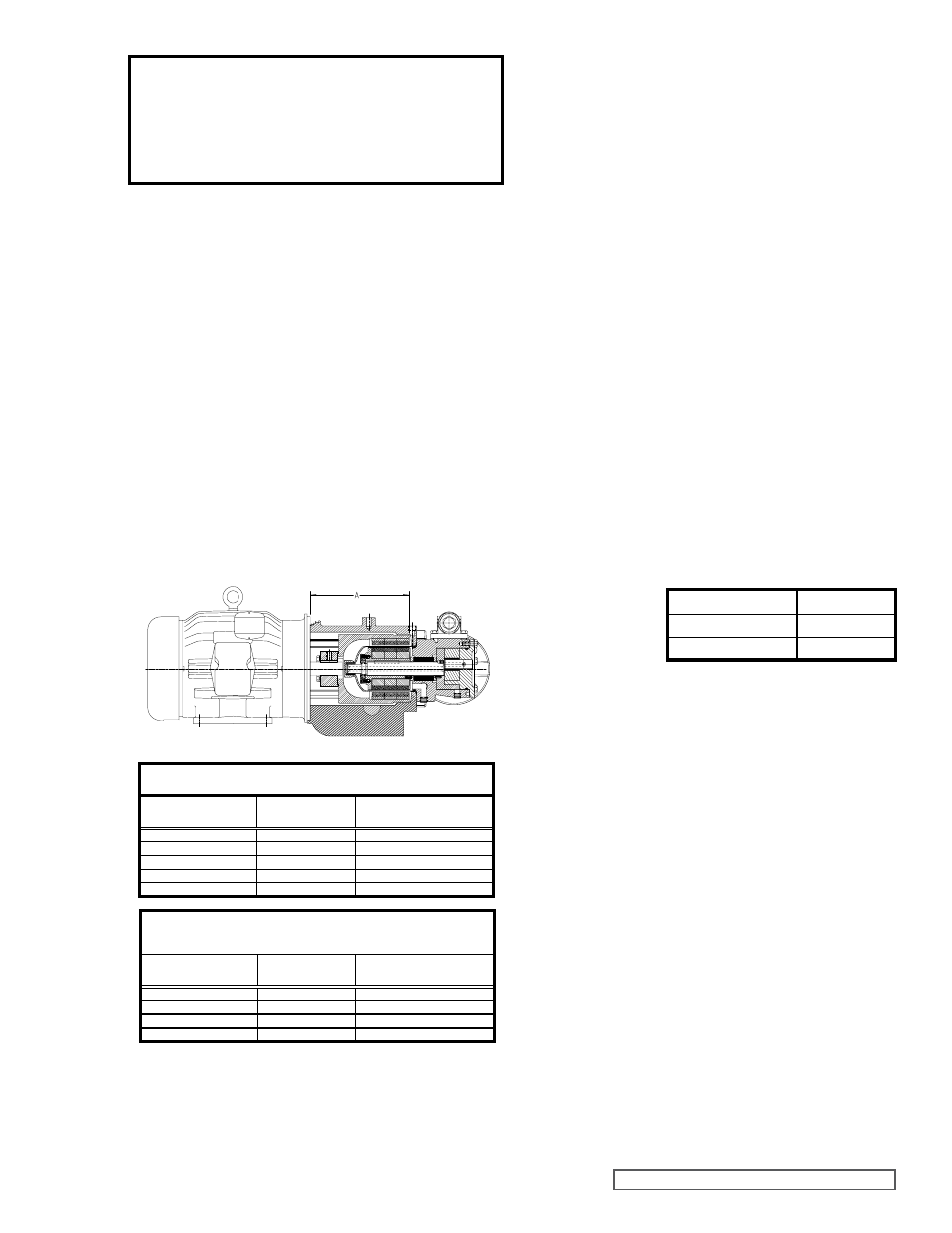

MD2-B Couplings:

Mount the outer magnet assembly. Locate the outer

magnet assembly per dimension

(See Figure 25).

MD2- C Couplings:

Units using a NEMA C-face frame motor will require

an adaptor plate. Mount the adaptor plate to the motor

if it was removed. Mount the outer magnet assembly.

Locate the outer magnet assembly per dimension

(See Figure 25).

Apply Loctite® and tighten the setscrews onto the motor

or bearing carrier key and shaft.

2. If the bracket is not fastened to a base, clamp it down.

Mount the motor or bearing carrier to the bracket. Reach

in and rotate the magnets by hand to make sure there is

no interference. If rubbing occurs check the dimension in

Figure 25 or contact the factory.

Dimensions are not the same between designs

3. Check to make sure the pump rotates freely by turning

the inner magnet assembly. Inspect the magnet to make

sure it has not picked up any foreign particles, which

could damage the pump. Make sure the canister O-ring

is in good condition and in place. Place the canister onto

Loctite® is a trademark of Henkel Consumer Adhesives, Inc.

MD2-B Magnets

(Measured from the motor face - not pilot)

Motor

“A” Dimension

(Inch)

“A” Dimension (Metric)

I.E.C. 110/112

7.89

200.4 MM

I.E.C. 132

8.68

220.5 MM

182TC/184TC

8.11

206 MM

213TC/215TC

8.49

215.7 MM

254TC/256TC

9.11

231 MM

MD2-C Magnets

(I.E.C. Measured from motor face

NEMA Measured from edge of adaptor plate)

Motor

“A” Dimension

(Inch)

“A” Dimension (Metric)

I.E.C.132

10.43

265 MM

I.E.C.160/180

11.61

295 MM

213TC-256TC

10.43

265 MM

284/286TC

10.43

265 MM

the pump and press on until the canister is in contact

with the pump mounting flange.

4. Use a fully threaded M10X120mm capscrew (jackscrew)

to guide the canister into the bracket. Thread the

capscrew all the way into the bracket as shown in

Figure 18, page 11. Use an overhead hoist to support

the pump if possible while guiding the canister into the

bracket opening.

Carefully back out the capscrew while guiding the

canister into the bracket. Secure the pump to the bracket

with four 12mm capscrews.

5. Be certain that the power supply to the pump is “Locked-

out”. Check that pump rotates freely by spinning the

motor fan blades or the bearing carrier shaft.

MD2-B BEARING CARRIER

ASSEMBLY

1. Place some Loctite® on the O.D. of the first bearing

and press into the housing bore. Position the bearing

spacer in the bore and insert the second bearing. Center

the bearing spacer then press in the shaft with one

external retaining ring on shaft. Press down until the

ring contacts the bearing race, then install the second

ring. Install the internal retaining ring into the bearing

housing.

See Figure 23, page 13.

2. Slide the outer magnet assembly onto the pump shaft.

Locate the outer magnet per dimension “A” listed below

then tighten the two setscrews.

See Figure 23, page 13.

Pump Design

“A” Dim.

U.S. Inch Design

8.49 inches

Metric Design

220.4 mm

“B” Coupling

Outer Magnet

Location Dimension*

MD2-C BEARING CARRIER

ASSEMBLY

Depending on the condition of the bearings, either replace or

repack existing bearings by cleaning and packing with multi-

purpose NLGI # 2 grease. Replace the lip seals if necessary.

See Figure 24, page13 for lipseal orientation.

1. Place the bearing housing milled-face down with cast

surface up. If the inner lip seal was removed, install with

the cup up. Install the cup of inner bearing into housing

(cup up).

2. Slide the inner tapered roller bearing cone onto the shaft

(cone down) and then the inner spacer followed by the

outer cone (cone up).

3. Guide shaft into the housing and into the inner lip seal.

Slide the tapered roller bearing outer cup into the housing

(cup down) and the bearing spacer collar onto shaft.

4. Thread in the end cap until it meets the outer cup. Install

the lockwasher and locknut. Secure the end of the shaft

in a vice with padded jaws then tighten the locknut.

Tighten the end cap until there is considerable drag on

the bearings, then back off the end cap approximately

10°. Secure the end cap into position by tightening the

two set screws.

5. Tighten the locknut again, then bend over the appropriate

lockwasher tab.

FIGURE 25

* Dimensions are not the same between designs