Viking Pump TSM141.1: G-LL 125/4125 User Manual

Page 9

SECTION TSM 141.1

ISSUE

E

PAGE 9 OF 16

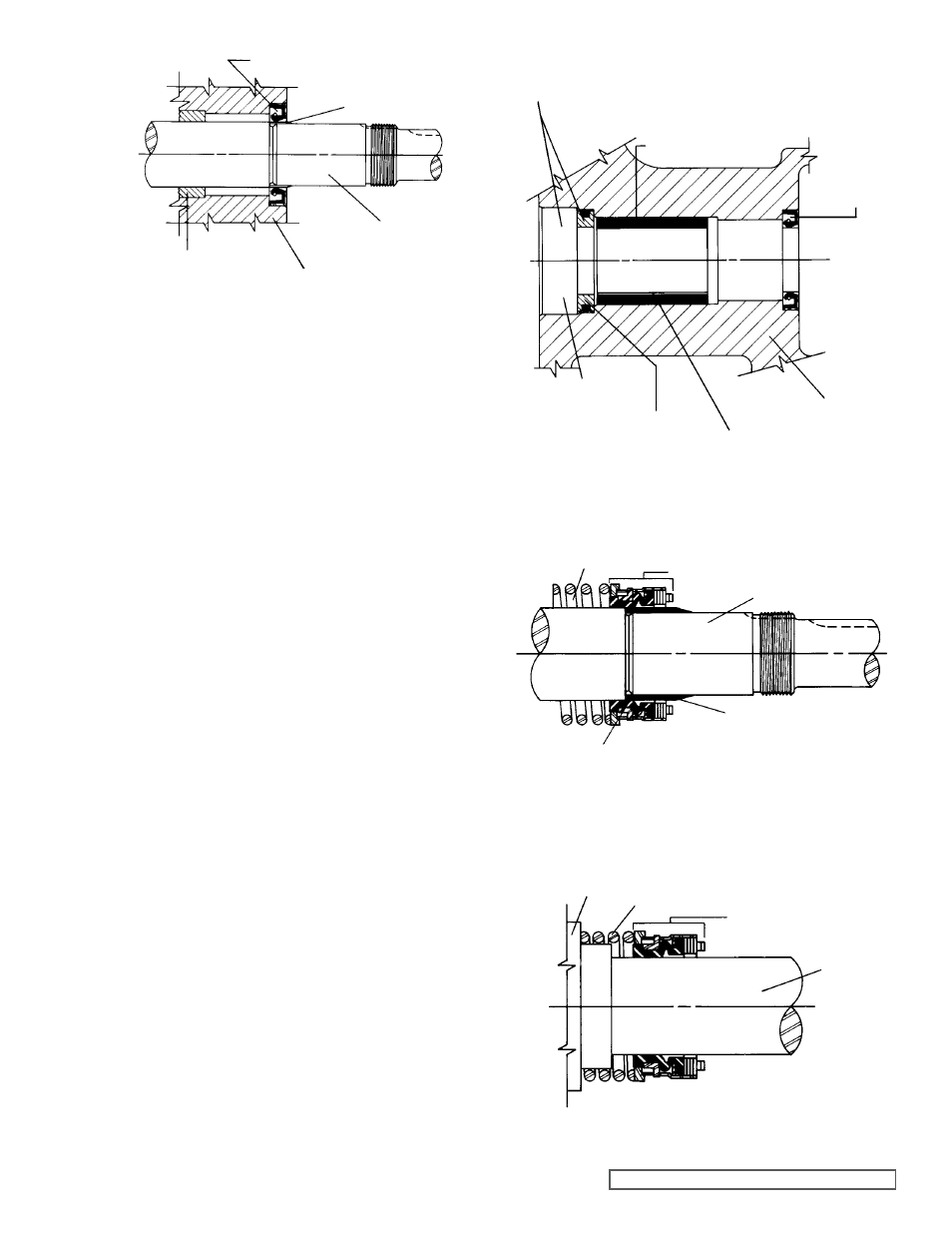

FIgURE 8

LIP SEAL FOR SEAL CHAMBER

TAPERED

INSTALLATION SLEEVE

BRACKET

BRACKET

BUSHINg

SHAFT

Prior to installing the rotating portion of the mechanical

seal, prepare and organize the rotor shaft, head and idler

assemblies and appropriate gaskets for quick assembly.

Once the rotating portion of the mechanical seal is installed

on the rotor shaft, it is necessary to assemble the parts as

quickly as possible to ensure that the seal does not adhere

to the shaft in the wrong axial position. The seal should

be expected to stick to the shaft after only a few minutes

setting time.

Never touch the sealing faces with anything except clean

hands or a clean cloth. Minute particles can scratch the seal

faces and cause leakage.

3. Coat

the idler pin with non-detergent SAE 30 weight oil

and place the idler and bushing on the idler pin in the

head. If replacing a carbon graphite bushing,

Refer to

Installation of Carbon graphite Bushings, page 14.

4. Clean the rotor hub and bracket seal housing bore.

Make sure both are free from dirt and grit. Coat the

outer diameter of the seal seat and the inner diameter

of the seal housing bore with non-detergent SAE 30

weight oil.

5. Start

the seal seat in the seal housing bore,

Refer to

Figure 9. If force is necessary, protect the seal face with

a clean cardboard disc and gently tap it in place with a

piece of wood.

6. Place

the tapered installation sleeve on the shaft,

Refer

to Figure 10. Sleeve is furnished with H, HL, K, KK, L,

LQ and LL size replacement mechanical seals. Coat the

rotor shaft, tapered installation sleeve and inner diameter

of the mechanical seal rotary member with a generous

amount of non-detergent SAE 30 weight oil. Petrolatum

may be used but grease is not recommended.

7. Place

the seal spring on the shaft against the rotor hub.

Refer to Figure 11.

8. Slide the rotary member, the lapped contact surface

facing away from the spring, over the installation sleeve

on the shaft until it is against the spring.

Do not compress the spring.

FIgURE 10

SPRINg

MECHANICAL SEAL ROTARY MEMBER

SHAFT

TAPERED

INSTALLATION SLEEVE

COAT ROTOR SHAFT, TAPERED INSTALLATION SLEEVE

AND INNER DIAMETER OF MECHANICAL SEAL WITH NON-

DETERgENT SAE 30 WEIgHT OIL BEFORE ASSEMBLY.

FIgURE 11

MECHANICAL SEAL

ROTARY MEMBER

SPRINg

SHAFT

ROTOR HUB

FIgURE 9

BRACKET

BUSHINg

LIP SEAL FOR

SEAL CHAMBER

BRACKET

BRACKET BUSHINg

LUBRICATION gROOVE

IN 12:00 O’CLOCK POSITION

SEAL SEAT

SEAL HOUSINg

BORE

COAT SEAL SEAT AND SEAL HOUSINg BORE

WITH NON-DETERgENT SAE 30 WEIgHT OIL

BEFORE ASSEMBLY.