Disassembly, Assembly, Danger – Viking Pump TSM141.1: G-LL 125/4125 User Manual

Page 5

SECTION TSM 141.1

ISSUE

E

PAGE 5 OF 16

1. Mark the head position relative to the casing before

disassembly to ensure proper reassembly. The idler pin,

which is offset in the pump head, must be positioned

toward and equal distance between port connections to

allow for proper flow of liquid through the pump.

Tilt the top of the head back when removing the head

to prevent the idler from falling from the idler pin.

Remove the head from the pump. Avoid damaging the

head gasket. If the pump is furnished with a pressure

relief valve, it need not be removed from the head or

disassembled at this point.

Refer to Pressure Relief

Valve Instructions, page 15.

If the pump has a jacketed head plate, it will separate

from the head when it is removed. The gasket between

the head and the jacket head plate must be totally

removed.

Always use a new gasket when assembling

the pump.

2. Remove the idler and bushing assembly.

3. Insert a length of hardwood or brass through the port

opening between the rotor teeth to keep the shaft from

turning. Bend up the tang of the lockwasher and with a

spanner wrench remove the locknut and lockwasher from

the shaft. There is no lockwasher on G size pumps.

4. Remove the packing gland nuts.

5. Tap the shaft forward approximately 0.5 inch and remove

the pair of half round rings under the inner bearing spacer

collar. There is no pair of half round rings on G, H and HL

size pumps.

DISASSEMBLY

DANgER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

Failure to follow above listed

precautionary measures may result in

serious injury or death.

ASSEMBLY

1. Install the bracket and/or idler bushing. If the bracket

bushing has a lubrication groove, install the bushing

with the groove at 12:00 o’clock position in bracket. If

replacing carbon graphite,

Refer to Installation of

Carbon graphite Bushings, page 14.

2. Coat the shaft of the rotor shaft assembly with non-

detergent SAE 30 weight oil. Start the end of the shaft

in the bracket bushing turning from right to left, slowly

pushing the rotor in the casing.

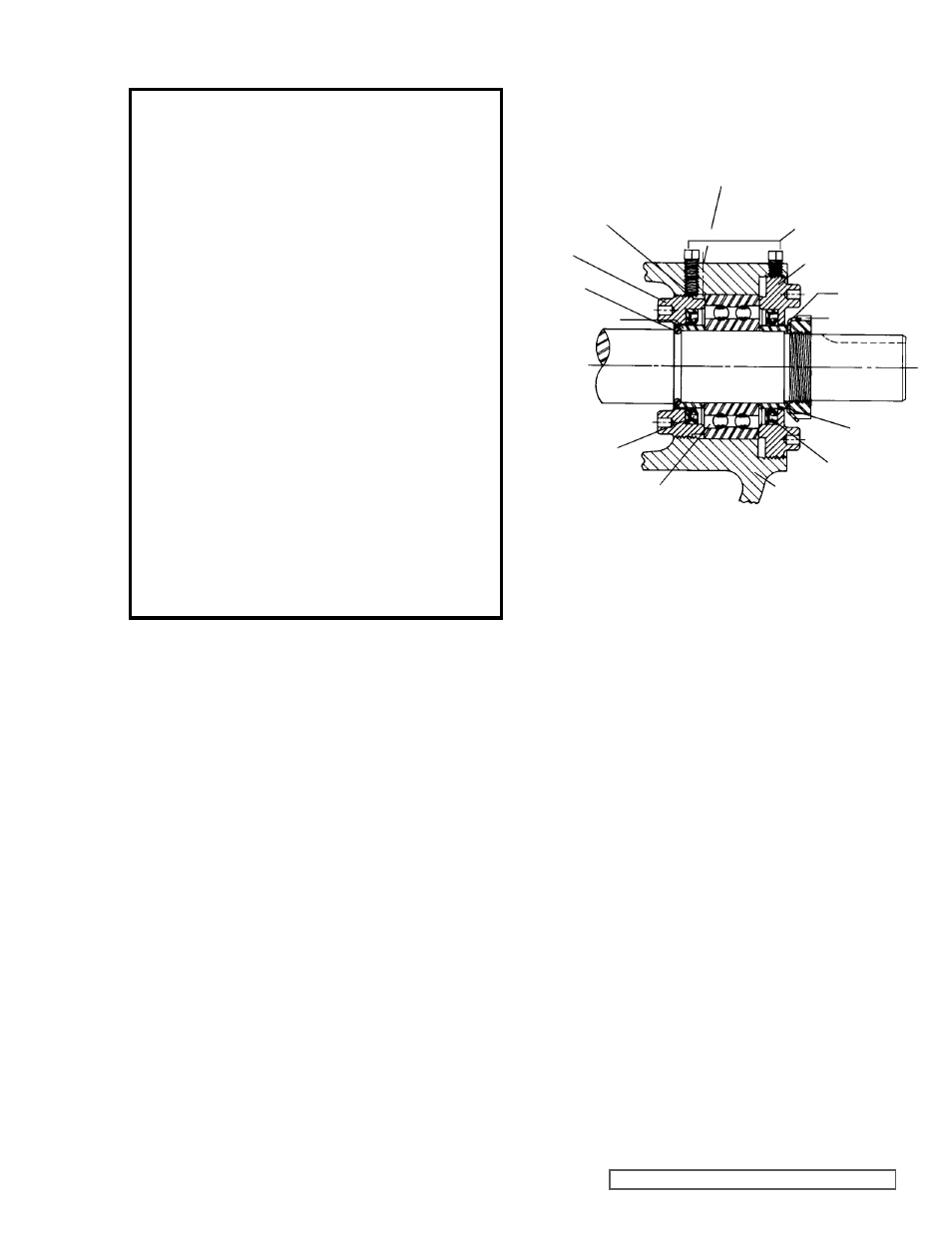

8.

Loosen the setscrews. Two on G, H and HL size pumps,

four on all other sizes. With a spanner wrench, remove

both end caps with lip seals. Remove the ball bearing

and spacer collars.

Refer to Figure 6.

9. Remove the packing and packing retainer washer.

10.

Clean all parts thoroughly and examine for wear and

damage. Check the lip seals, ball bearing, bushings

and idler pin and replace if necessary. Check all other

parts for nicks, burrs, excessive wear and replace if

necessary.

Wash the bearings in clean solvent. Blow out the

bearings with compressed air. Do not allow the bearings

to spin; turn them slowly by hand. Spinning the bearings

will damage the race and balls. Make sure the bearings

are clean, then lubricate with non-detergent SAE 30

weight oil and check for roughness. Roughness can be

determined by turning the outer race by hand.

11.

Casing can be checked for wear or damage while

mounted on the bracket.

6. Carefully remove the rotor and shaft to avoid damaging

the bracket bushing.

7.

Remove the packing gland from the side of the bracket.

gREASE FITTINg

SETSCREWS

OUTER END CAP

LOCKWASHER

LOCKNUT

OUTER

SPACER

COLLAR

OUTER LIP

SEAL

BRACKET

BALL BEARINg

INNER

LIP SEAL

INNER SPACER

COLLAR

HALF

ROUND

RINgS

INNER

END CAP

NYLON INSERT

FIgURE 6