Mild steel 100a o, Plasma / air shield – Tweco XT-300 Torch Data for Distributor UltraCut-100 AG User Manual

Page 7

Manual 0-4730 Rev. AG

8-7

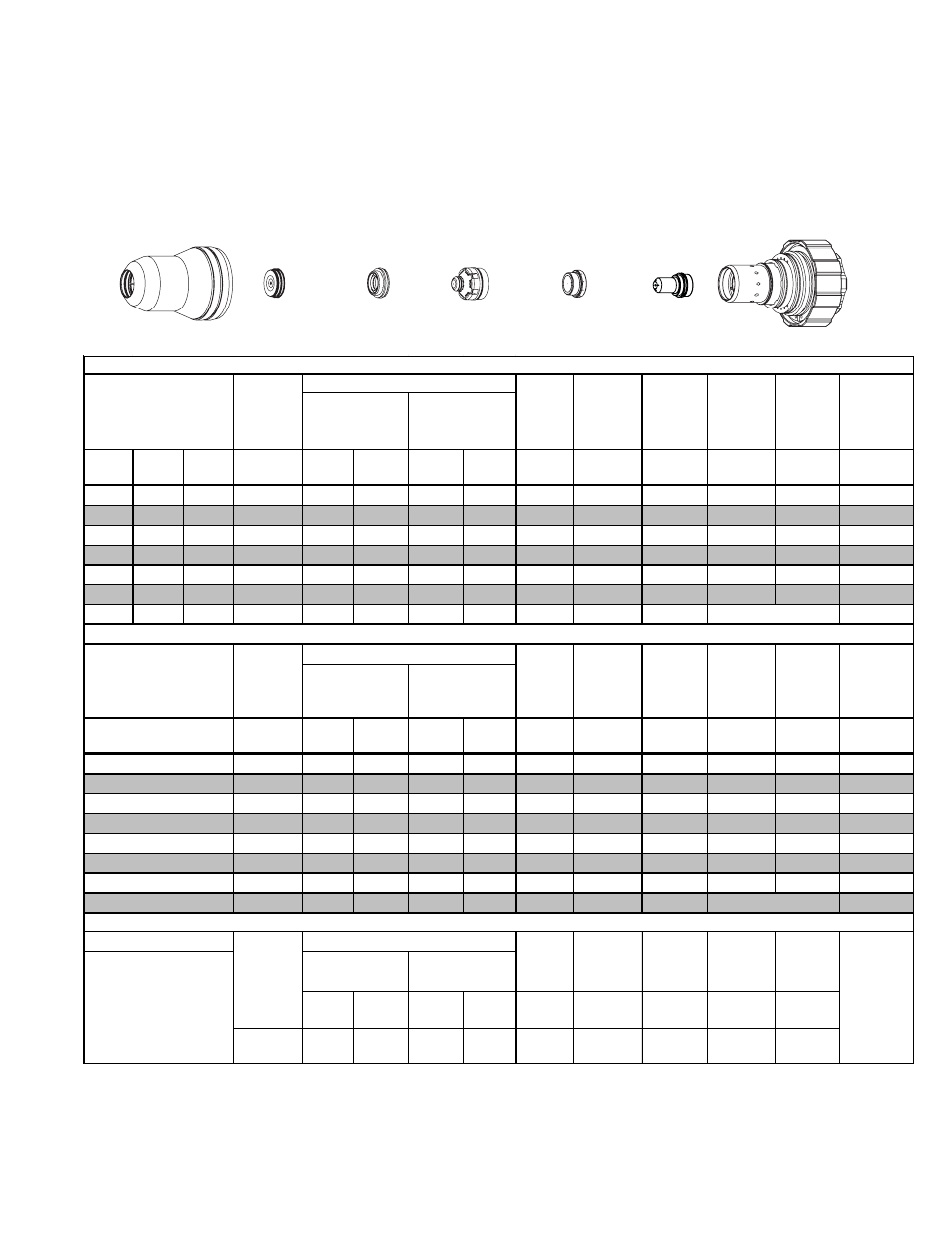

TORCH DATA

Mild Steel

100A

O

2

Plasma / Air Shield

Shield

Gas Distributor

21-1272

Cartridge

21-1020

Electrode

21-1171

Plasma

Gas Distributor

21-1041

Tip

21-1153

Shield Cap

21-1027

Shield Cup

21-1016

Art # A-07665

(ga)

(in)

inch

(PSI)

Ball

(PSI)

Ball

(PSI)

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

10

0.135

40

55

120

80

120

138

0.070

280

0.200

0.2

0.065

3/16

0.188

40

55

120

80

120

140

0.090

190

0.200

0.2

0.070

1/4

0.250

40

55

120

80

120

141

0.100

150

0.200

0.3

0.078

3/8

0.375

40

55

120

80

120

143

0.110

95

0.250

0.4

0.085

1/2

0.500

40

55

120

80

120

147

0.120

64

0.300

0.6

0.097

5/8

0.625

40

55

120

80

120

148

0.120

50

0.350

0.8

0.100

3/4

0.750

40

55

120

80

120

157

0.150

25

0.125

(Bar)

Ball

(Bar)

Ball

(Bar)

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

2.8

55

8.3

80

8.3

139

2.0

6120

5.1

0.2

1.7

2.8

55

8.3

80

8.3

140

2.3

4670

5.1

0.2

1.8

2.8

55

8.3

80

8.3

141

2.5

4030

5.1

0.3

1.9

2.8

55

8.3

80

8.3

142

2.7

3080

5.7

0.4

2.1

2.8

55

8.3

80

8.3

144

2.8

2300

6.5

0.4

2.2

2.8

55

8.3

80

8.3

146

3.0

1800

7.3

0.6

2.4

2.8

55

8.3

80

8.3

148

3.1

1370

8.5

0.7

2.5

2.8

55

8.3

80

8.3

157

3.8

640

3.2

Ball

Press

Ball

Press

Volts

in ±0.005 /

mm ±0.1

ipm /

mm/min

in ±0.005 /

mm ±0.1

(sec)

20 psi

1.4 bar

50

40 psi

2.8 bar

100

80 psi

5.5 bar

190

0.12

3

300

7600

0.12

3

0

Burn-through

may occur

for thicknesses

< 1/16" (0.063") / 1.6 mm.

Plasma

Pressure (N

2

)

Shield

Pressure (N

2

)

Marking (w ith 100A Mild Steel Parts)

15A Arc Current

Pre Flow

Pressure

(N

2

)

Cut Flow Rates / Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Marking

quality

degrades

as

thickness

decreases

Pierce

Delay

Kerf Width

@ Rec.

Speed

Edge Start Only

Edge start Only

Pierce

Delay

Kerf Width

@ Rec.

Speed

20

8

10

12

15

(mm)

4

5

6

100A Mild Steel XTL O

2

/Air

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Plasma (O

2

) Shield

(Air)

Initial

Piercing

Height

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Travel

Speed

Initial

Piercing

Height

Plasma (O

2

) Shield

(Air)

Arc

Voltage

Torch

Working

Height