Stainless steel 50a n, Plasma / h, O shield – Tweco XT-300 Torch Data for Distributor UltraCut-100 AG User Manual

Page 11

Manual 0-4730 Rev. AG

8-11

TORCH DATA

(ga)

(in)

inch

(PSI)

Ball

(PSI) Ball

(PSI)

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

14

0.078

60

62

120

4

55

117

0.110

170

0.200

0.2

0.043

12

0.109

60

62

120

4

55

119

0.110

150

0.200

0.2

0.047

(Bar)

Ball

(Bar) Ball

(Bar)

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

4.1

62

8.3

4

3.8

117

2.8

4310

5.1

0.2

1.1

4.1

62

8.3

4

3.8

120

2.8

3660

5.1

0.2

1.2

* Pressure of the water supply line should be regulated by customer pressure regulator.

Note1: Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the

ohmic sensing circuit.

Note2: Water source used for shield must be demineralized.

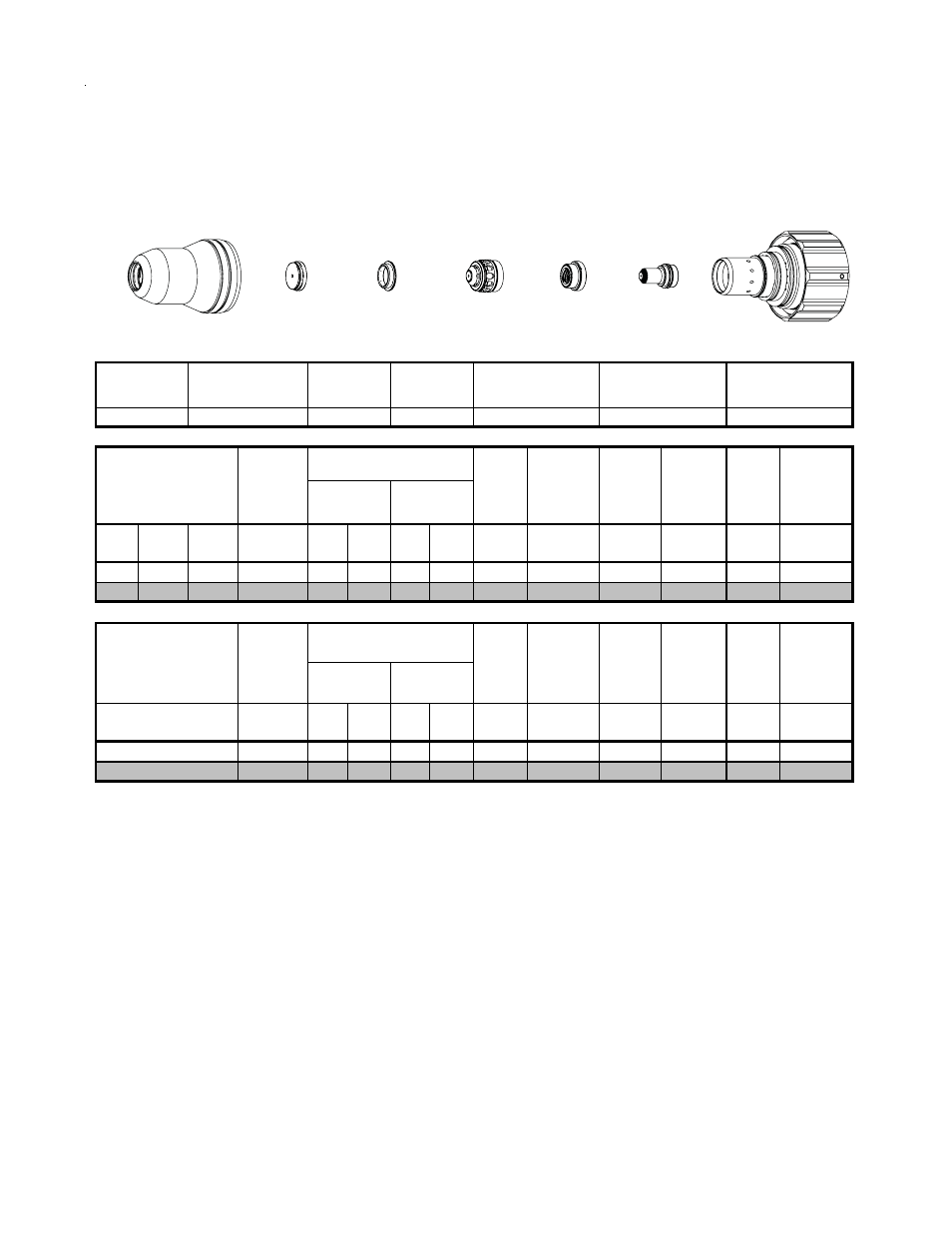

Stainless Steel

50A

N

2

Plasma / H

2

O Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Electrode

Cartridge

21-1041

21-1078

21-1020

21-1016

21-1034

21-1274

21-1060

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

Plasma

(N

2

)

Shield

(H

2

O)*

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

Plasma

(N

2

)

Shield

(H

2

O)*

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later

(mm)

2

3

BOLD TYPE indicates maximum piercing parameters.

Electrode

Shield Cap

Tip

Shield Gas

Distributor

Plasma Gas

Distributor

Cartridge

Shield Cup

This Art Is For Reference ONLY

Art # A-07958_AB