Transtig 170pi – Tweco 170Pi Transtig User Manual

Page 59

TRANSTIG 170Pi

Manual 0-5241

5-3 POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

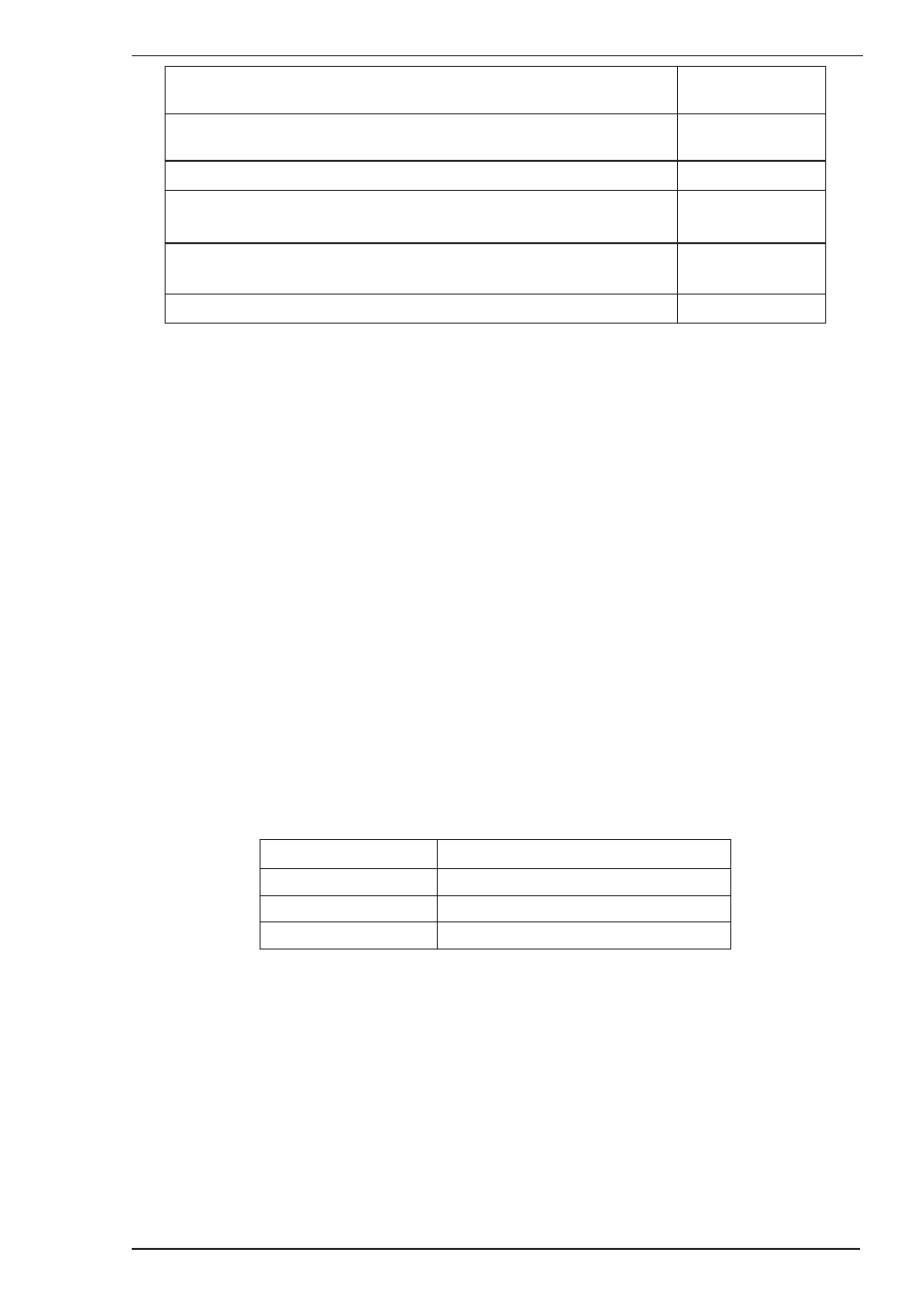

Components to be Tested

Minimum Insulation

Resistance (MΩ)

Input circuit (including any connected control circuits) to welding circuit

(including any connected control circuits)

5

All circuits to exposed conductive parts

2.5

Welding circuit (including any connected control circuits) to any auxiliary

circuit which operates at a voltage exceeding extra low voltage

10

Welding circuit (including any connected control circuits) to any auxiliary

circuit which operates at a voltage not exceeding extra low voltage

1

Separate welding circuit to separate welding circuit

1

Table 5-2: Minimum Insulation Resistance Requirements: Cigweld Inverter Power Sources

C. Earthing

The resistance shall not exceed 1Ω between any metal of a power source where such metal is required

to be earthed, and -

1. The earth terminal of a fixed power source; or

2. The earth terminal of the associated plug of a transportable power source

Note that due to the dangers of stray output currents damaging fixed wiring, the integrity of fixed wiring

supplying Cigweld welding power sources should be inspected by a licensed electrical worker in accordance

with the requirements below -

1. For outlets/wiring and associated accessories supplying transportable equipment - at least once

every 3 months; and

2. For outlets/wiring and associated accessories supplying fixed equipment - at least once every 12

months.

D. Voltage Reduction Device (VRD)

Units fitted with VRD's, shall have the periodic tests outlined in Table 6-2 below conducted by an accredited

CIGWELD service provider. Testing shall be conducted at intervals as outlined below -

1. For transportable equipment, at least once every 3 months; and

2. For fixed equipment, at least once every 12 months.

Description

Required Parameters

VRD Open Circuit Voltage Less than 35V; at nominal input voltage

VRD Turn OFF Resistance

Less than 200 ohms

VRD Turn ON Time

Less than 0.3 seconds

Table 5-3: VRD Periodic Tests

E. General Maintenance Checks

Welding equipment should be regularly checked by an accredited Cigweld Service Provider to ensure

that:

1. Flexible cord is of the multi-core tough rubber or plastic sheathed type of adequate rating, correctly

connected and in good condition.

2. Welding terminals are in suitable condition and are shrouded to prevent inadvertent contact or short

circuit.

3. The Welding System is clean internally, especially from metal filing, slag, and loose material.