07 shielding gas regulator operating instructions, Shielding gas regulator operating instructions -14, Transtig 170pi – Tweco 170Pi Transtig User Manual

Page 31

TRANSTIG 170Pi

Manual 0-5241

3-13

INSTALLATION, OPERATION AND SETUP

Note that when the unit is powered on the mode selection control will automatically default to LIFT TIG/HF

TIG mode. This is necessary so as to prevent inadvertent arcing should an electrode holder be connected

to the unit and mistakenly be in contact with the work piece during power up.

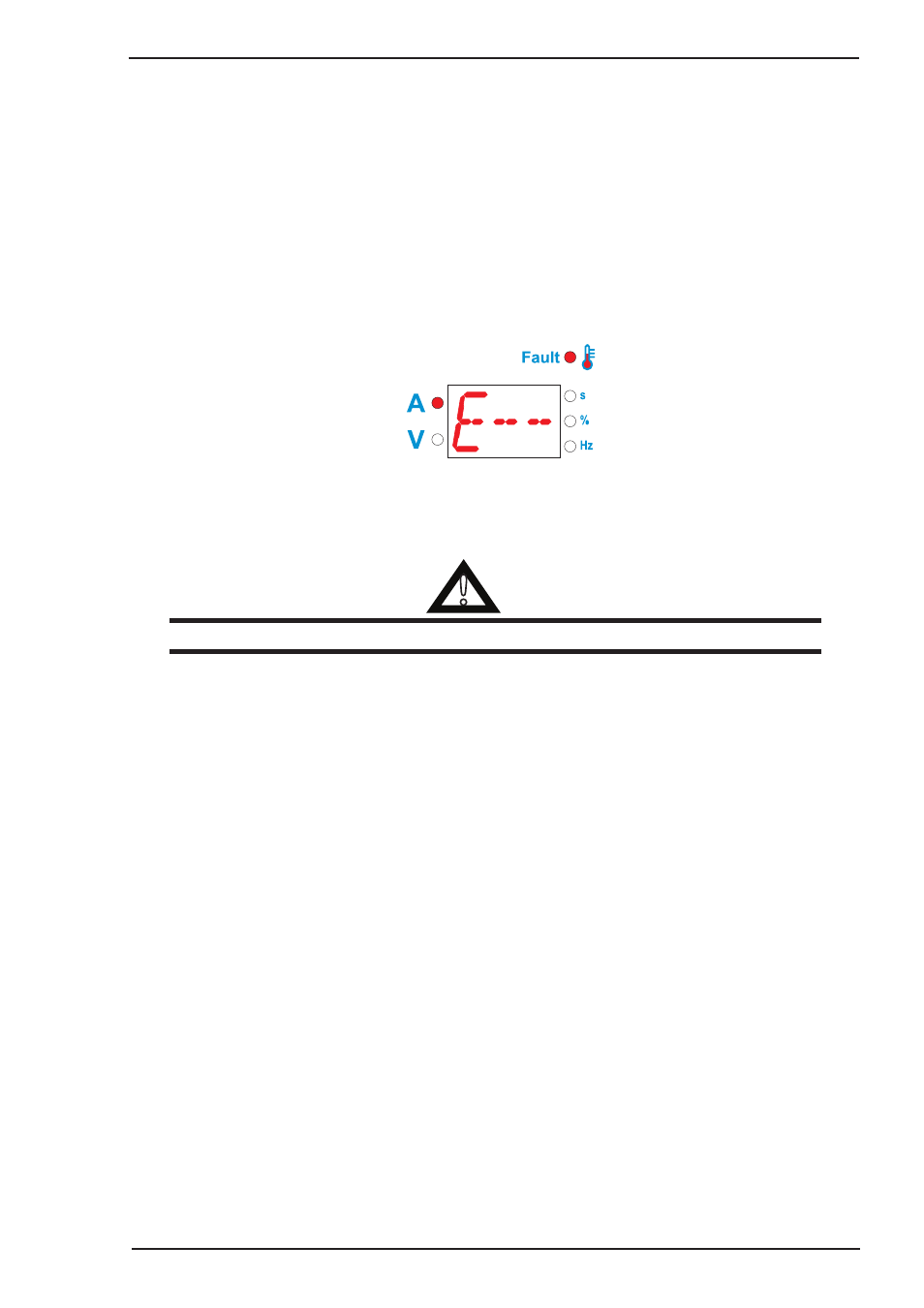

11. Thermal Overload Indicator

This welding power source is protected by a self resetting thermostat. The indicator will illuminate if the

duty cycle of the power source has been exceeded. Should the thermal overload indicator illuminate the

output of the power source will be disabled. Once the power source cools down this light will go OFF and

the over temperature condition will automatically reset. Note that the mains power switch should remain

in the on position such that the fan continues to operate thus allowing the unit to cool sufficiently. Do not

switch the unit off should a thermal overload condition be present.

The display will also show error code E-- in the event of an over current or over temperature.

A-11665

12. Shielding Gas Inlet

The Shielding Gas Inlet connection is used to supply the appropriate shielding gas to the unit. Refer to

section 3.08 for GTAW (TIG) set up details.

!

WARNING

Only Inert Shielding Gases specifically designed for welding applications should be used.

13. On / Off Switch

This switch is used to turn the unit on/off.

14. Fan on Demand

The Transtig 170Pi is fitted with a fan on demand feature. Fan on demand automatically switches the cooling

fan off when it is not required. This has two main advantages; (1) to minimize power consumption, and

(2) to minimize the amount of contaminants such as dust that are drawn into the power source.

Note that the fan will only operate when required for cooling purposes and will automatically switch off

when not required.