Ultrafeed a 2000 – Tweco A 2000 Ultra-Feed User Manual

Page 34

ULTRAFEED A 2000

5-4

May 1, 2006

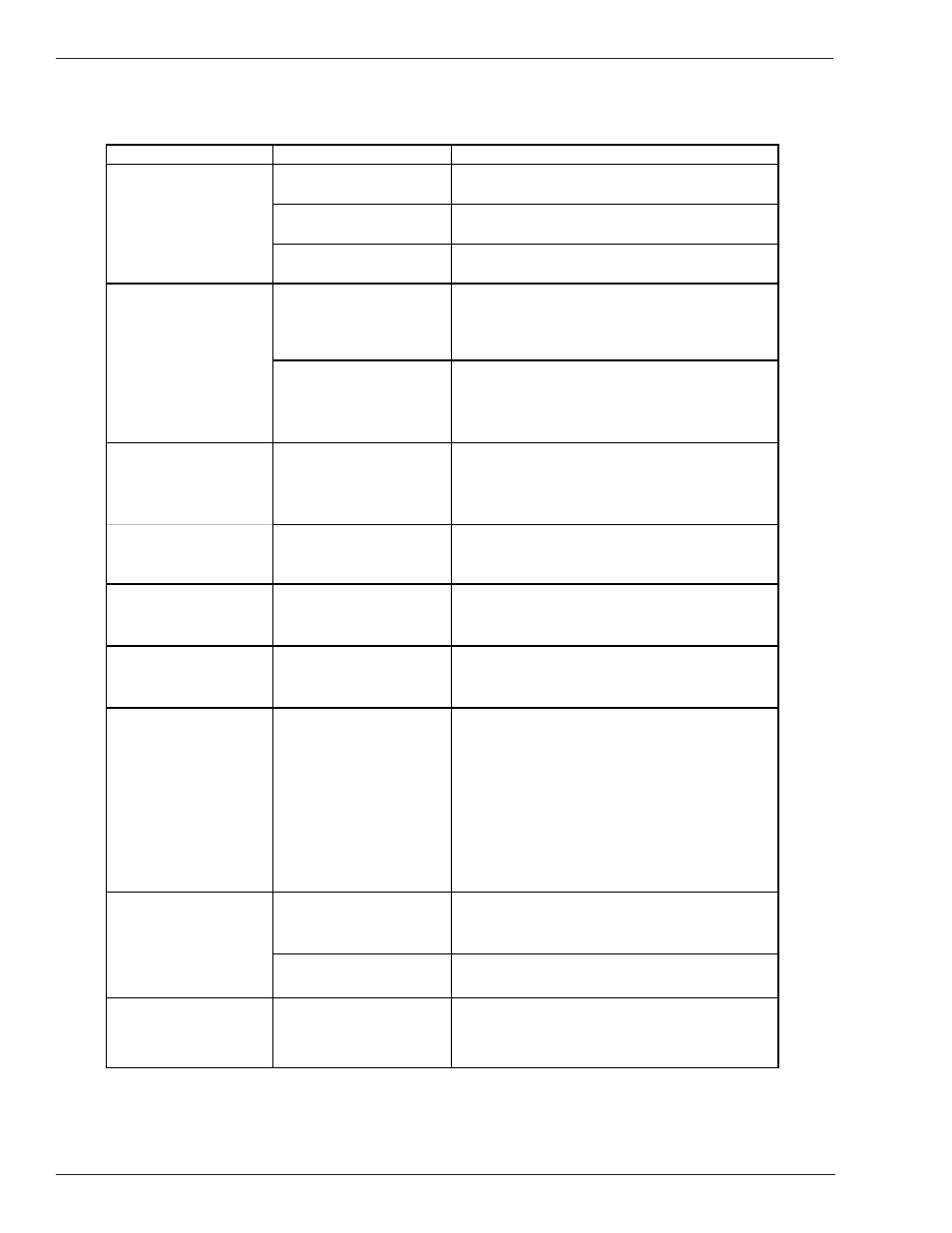

FAULT

CAUSE

REMEDY

1. Too much pressure

on feed rolls.

a. Decrease feed roll pressure.

2. Input and output wire

guides misaligned.

a. Realign wire guides. Refer to

section 3.06.

3. Incorrect cable liner

or contact tip.

a. Refer to table in welding

gun manual for correct size.

1. Faulty gun trigger

switch or connection.

a. Check gun switch recepticle connection.

b. Check continuity of gun trigger switch leads

with trigger depressed. Repair or replace

as needed.

2. Faulty feed drive

motor or connections.

a. Check feed drive motor connections.

Repair or replace as needed.

b. Check motor brushes for excessive wear.

Replace as needed.

E. Motor continues to

run after gun switch

has been released.

1. Electrical short with

gun leads.

a. Check for shorted welding gun trigger

leads. Repair or replace welding gun.

b. Check the gun switch recepticle on

the feeder for a shorted condition.

F. No arc voltage

(Volts) control.

1. WSP/Local switch in

wrong position.

a. Make sure the WSP/Local switch on the power

supply is in the "local" position. Refer to the

power supply owner's manual.

G. Wire does not

feed with INCH

button depressed.

1. Loose or faulty

connections.

a. Check the INCH/PURGE switch located

on the wire feeder for loose or faulty

connections. Repair or replace as needed.

H. Gas does not flow

with PURGE button

depressed.

1. Switch connection

a. Check the INCH/PURGE switch located

on the wire feeder for loose or faulty

connections. Repair or replace as needed.

I. Wire feeds but

no gas flows.

1. Gas cylinder flow

restricted or empty.

a. Check the gas cylinder for gas. Replace

as needed.

b. Check for possible restriction in the gas

line. Repair or replace as needed.

c. Check to see if welding gun nozzle is

plugged. Clean or replace as needed.

D. Check connections on the gas valve for

faulty or loose connections. Tighten or

replace as needed.

1. Loose or faulty

connections.

a. Check all connections from gas cylinder

to welding gun. Tighten or replace

as needed.

2. Regulator/Flow

Meter problem

a. Check for foreign material in gas valve.

Clean or replace as needed.

K. Wire feeds but

electrode wire is not

hot - there is no arc.

1. Faulty power supply

control cable.

a. Check continuity of pins A and B of the

19 pin power supply control cable.

Replace cable as needed.

C. Wire wraps around

feed rolls.

D. Wire does not feed

with gun switch

depressed.

J. Gas flows all the

time or leaks.

Table 5-1b: Trouble Shooting Continued