Section 5: service, 01 cleaning the unit, 02 cleaning the feed rolls – Tweco A 2000 Ultra-Feed User Manual

Page 31: 03 feedhead maintenance, 04 system maintenance, 05 troubleshooting hints, Section 5, Service -1, Ultrafeed a 2000

ULTRAFEED A 2000

May 1, 2006

5-1

SECTION 5:

SERVICE

5.04 System Maintenance

Scope

The troubleshooting guide is intended to be used by

qualified service technicians. The troubleshooting guide

contains information which can be used to diagnose and

correct unsatisfactory operation or failure of the various

components of the wire feeder. Each symptom of trouble

is followed by a list of probable causes and the procedure

necessary to correct the problem.

Safety

To ensure safe operation and service, read this entire

manual before attempting to service or repair this

machine. The service technician may be asked to check

voltage levels while the machine is turned ON. To assure

safety, use care and follow all instructions accordingly.

5.05 Troubleshooting Hints

Examine connections for proper assembly and contact

before replacing an electrical component or printed circuit

board. Wire lugs should be in tight contact with the lead’s

conductor and should be crimped to the lead’s insulation.

The mating surfaces of the connection should be clean

and free of oxidation.

Faulty connections or wiring problems are often the cause

of an equipment malfunction!

Do not pull on wires to disassemble connections. Firmly

grasp each lug or connector when disconnecting. Pulling

on wires for disassembly can damage the integrity of the

connection and cause future malfunctions.

Prior to disassembly or servicing of the machine, note

the wiring and connections in the machine. Reassembling

should place the wires in the same location and routing

as received from the factory. Keep wires and leads away

from hot parts and sharp objects.

All signals referenced in the following troubleshooting

guide can be measured with a digital multimeter (DMM).

5.01 Cleaning The Unit

Periodically, clean the inside of the wire feeder and feedhead

assembly by using a vacuum cleaner or clean, dry,

compressed air of not more than 25 psi/172 kPa/1.72 bar

pressure. After cleaning the unit, check all electrical

components for loose or faulty connections and correct if

necessary.

5.02 Cleaning The Feed Rolls

Clean the grooves on the lower drive roll frequently. This

cleaning operation can be done by using a small wire

brush. Also, wipe off or clean the grooves on the upper

roll. After cleaning the feed rolls, tighten the feed roll

retaining knobs accordingly.

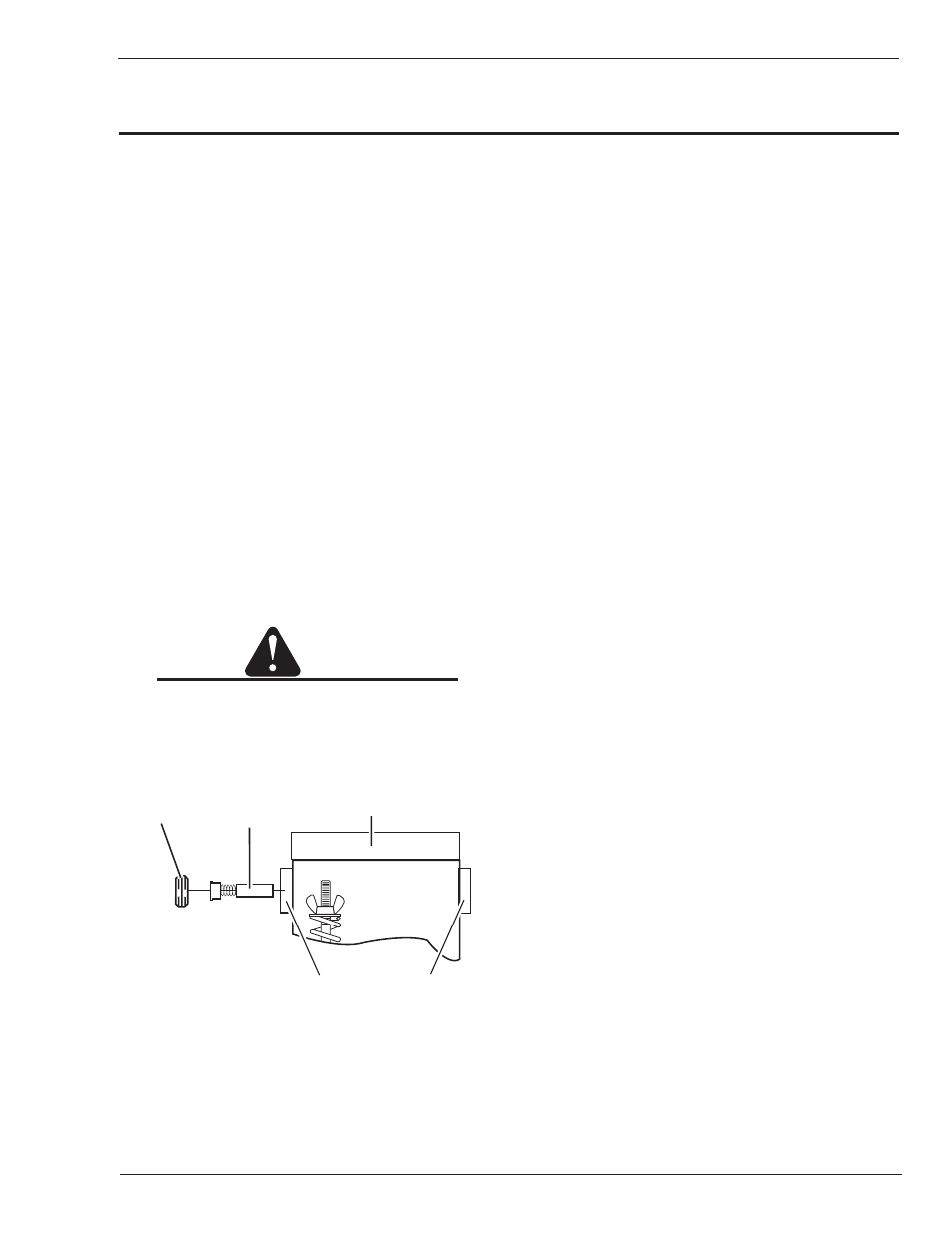

5.03 Feedhead Maintenance

The only point of maintenance in the feedhead assembly

is the motor brushes. Inspect these about every 300 hours

of operation. When these brushes are worn to about 1/8"

(3.2 mm), new brushes should be installed.

CAUTION

Neglect in brush maintenance may cause

damage to the drive motor commutator

resulting in a shorter motor operating life.

Feed Motor

Brush Holders

Brush

407191-2

Cap

407190-1

Art # A-04195

Figure 5-1: Brush Maintenance