03 basic troubleshooting – Tweco CE Ultima 150 User Manual

Page 31

Manual 0-2530

25

SECTION 5: GENERAL MAINTENANCE

2. Flushing the System

As part of general maintenance, periodically the

cooling system should be flushed. To flush the sys-

tem, remove the hose fitting at the filter end of the

Coolant Filter Assembly and drain into an appro-

priate container. Do not turn on the pump. Grav-

ity flow will drain the Reservoir.

3. Coolant Conductivity

The coolant conductivity LED on the front panel

must be green for normal operation. If the LED is

red then flush the old coolant from the system.

To flush the cooling system, remove the hose fitting

at the filter end of the Coolant Filter Assembly and

drain into an appropriate container. Do not turn

on the pump. Gravity flow will drain the Reser-

voir. Refill cooling system with Thermal Arc

®

Torch

Coolant.

CAUTIONS

Handle and dispose of the used coolant per recom-

mended procedures.

Do Not turn on the pump. Running the cooling

pump dry will cause premature failure of the pump.

Pump pressure is preset at the factory and should

not require attention.

5.03 Basic Troubleshooting

This manual covers basic troubleshooting that requires

limited disassembly and measurements. Most common

problems can be resolved with the information provided

in this section.

For major troubleshooting for this product, see the UL-

TIMA-150 Service Manual No. 0-2503.

NOTE

If major complex assemblies are faulty, the unit must

be returned to an authorized service center for re-

pair.

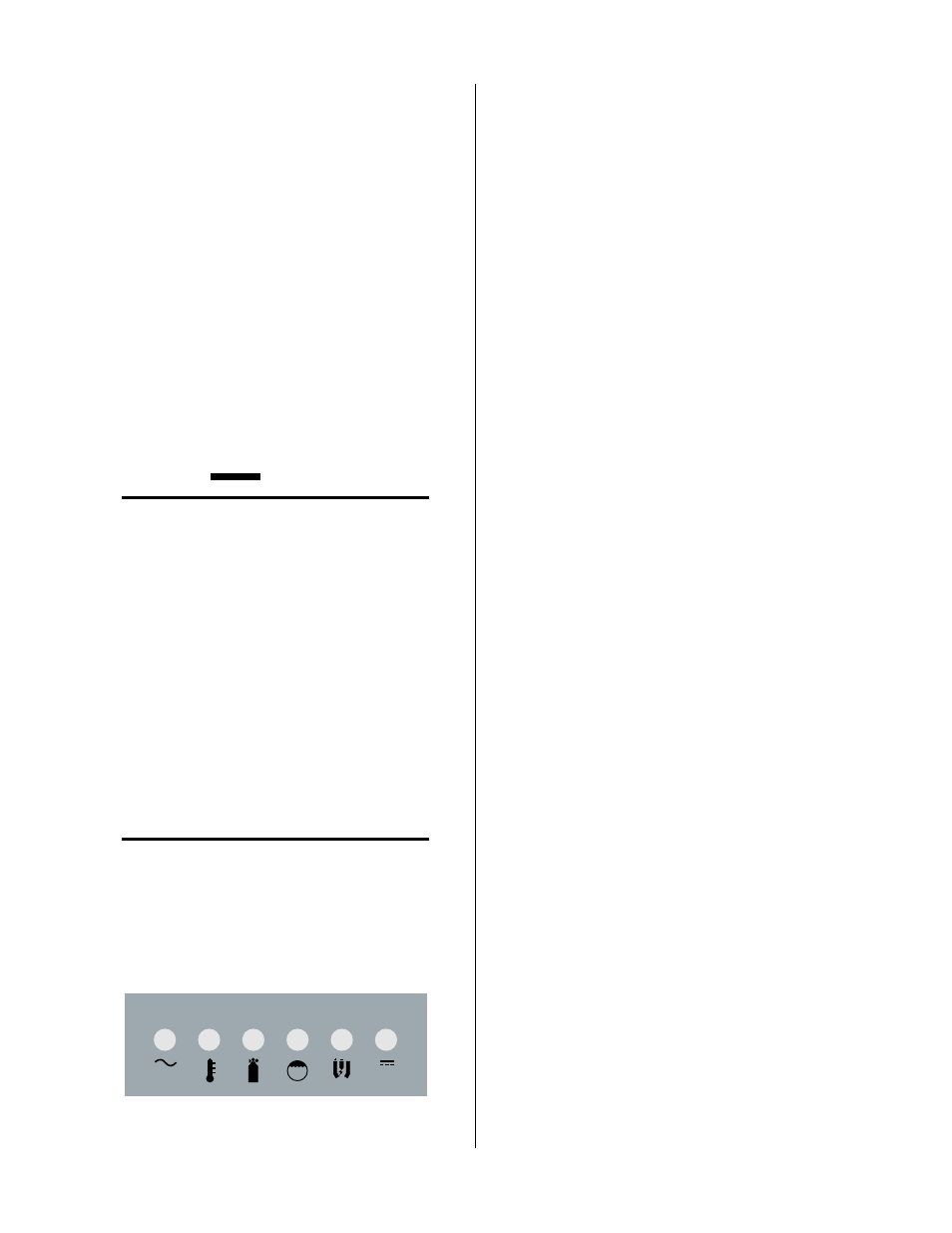

The ULTIMA-150 Power Supply provides Status Indica-

tor Lights to indicate potential source of most problems.

Check here to identify the nature of a problem.

COOL

PILOT

DC

GAS

TEMP

AC

A-00823

Figure 5-3 Front Panel Status Indicator Lights

A. AC Power Problems

1. AC light indicator not on; fan does not operate

a. Switch at customer's main power panel in OFF position

• Close main power panel switch

b. Input power fuse (F1) blown or loose

• If blown, double-check input voltage against

voltage selection inside unit. Replace input

power fuse (Refer to Section 5.04, Basic Parts

Replacement)

c. Incorrect voltage applied

• Check input line for correct voltage

d. Customer's main power fuse(s) blown or loose

• Check main power fuse(s) and replace as re-

quired

e. Input power not properly connected to customer's main

power panel

• Check that input power is present and unit is

properly connected (refer to Section 3.04, Pri-

mary Input Power Connections.

f. Defective input power cable

• Check cable and replace if faulty

2. AC light is on; fan operates slow

a. Incorrect voltage selection

• Check High-Low Voltage Selection. Must be re-

placed by a Thermal Dynamics EMI Suppres-

sion Cable.

B. Temperature Problems

1. Temp light is RED

Overtemperature of the power supply or coolant will

immediately disable the power supply output. The

recirculator pump remains running to cool down the

system and coolant

a. Obstructed air flow outside power supply

• Check to insure there is adequate space around

power supply. See Section 3.02, Site Location,

for more information

b. Exceeded duty cycle

• Exceeded duty cycle causing power supply or

coolant to overheat. Refer to Section 2.03, Speci-

fications, for correct Amps and Duty Cycle